Screw pump restores use of diversion dam, protects fish

Invented several thousand years ago and adapted in several ways in modern times, in its basic form the screw pump consists of a long continuous spiral on a shaft, the assembly being inclined at an angle. The shaft rotates in a semi-circular open channel or a closed tube, and the lift achieved is approximately half the length of the screw. In practice the screw length is limited to about 50 feet, which will produce a lift of approximately 25 feet. Rotational speeds are low, typically 30 to 60 rpm, and it is largely this characteristic that has helped resolve the fish population problem in California.

Diversion dam obstructed fish trying to reach spawning areas

At the Red Bluff Diversion Dam in Red Bluff, CA, water from the Sacramento River is impounded and diverted into a stilling basin. From there it flows southward via the Tehama-Colusa Canal for farm irrigation use and to wildlife refuges in the northwest portion of California's Central Valley.

But the diversion dam, installed in 1964, created a problem by delaying the passage of anadromous salmon and steelhead trout during their upstream migration, and as a result hindering successful spawning. In addition, predator fish tended to congregate in the dam's tail-waters, feeding on disorientated juvenile salmon as they moved downstream under the gates of the dam.

In 1994, the winter run Chinook salmon were listed as "protected" under the Endangered Species Act. Because the Red Bluff Diversion Dam was reducing the population of this species, the Federal and State Fish and Wildlife agencies (F&W) returned the Sacramento River at Red Bluff to run-of-the-river conditions.

Dam gates ordered to be opened

To solve the immediate problem, the U.S. National Marine Fisheries Service directed the U.S. Bureau of Reclamation to raise the gates on the Red Bluff Diversion Dam. The gates were ordered to remain out of the water, with the understanding that the Bureau would complete construction of a research pumping plant at the diversion dam by the end of 1994. This open-gate mode of operation allowed protected winter run adult salmon to proceed unimpeded to their upstream spawning grounds, and provided open passage for winter run juveniles out of the spawning grounds.

Results of concurrent pilot testing by Pacific Gas & Electric and the F&W at the U.S. Army Corps of Engineers Don Claussen Fish Hatchery concluded that a modified screw pump offered an acceptable and safe method of lifting downstream migrant salmon and steelhead trout. Successful pilot tests, together with the anticipated low salmon mortality rate, prompted the California Department of Fish and Game to approve the specially adapted screw pump for this application. The unit, a USFilter CPC screw pump, is said to be the first and only pump design ever approved by the department for use in pumping live fish. The pump adapted for the task is an Internalift model supplied by <%=company%> of Sturbridge, MA.

Screw pump system successful in passing fish upstream unharmed

The Red Bluff pumping facility started handling fish in March of 1996. The purpose of the research project was to identify the fish species that would be entrained during pumping and establish the mortality and injury rates of fish passing through the screw pump. During the testing period, the survival rate of the preferred species of fish passing through the pump exceeded all expectations.

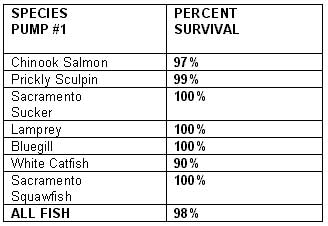

Of the nineteen identified species of fish lifted through the system so they could proceed upstream safely, 98 percent survived. More recent information continues to confirm that the new system based on the modified Internalift pump is resulting in a 98 percent survival rate. The table below shows survival rates of fish species most frequently taken at the Red Bluff research pumping station during entrainment trials in 1995 and 1996. A final report on the project is to be released in the fall of 2000.

Edited by Ian Lisk

Editor Emeritus, Water Online