Rethinking Optimization From Planning Through Long-Term Operation

By Christine deBarbadillo

“Optimization” isn’t a new word in the water sector, but it has a broader meaning now as utilities plan for the future.

Most treatment facility owners and operators recognize the importance of optimizing operations efficiency. Making the most of existing treatment is a proven way to expand capacity and/or improve performance, so optimization is well-known and long-revered as an important strategy in that respect.

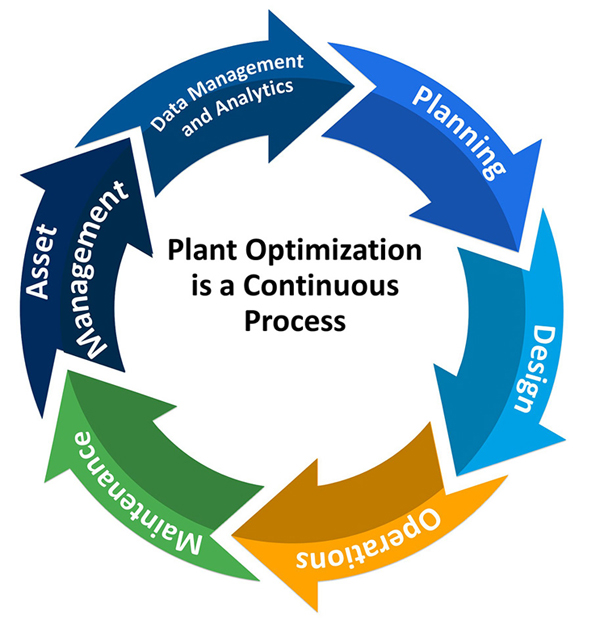

But not everyone realizes that optimization has a much broader application. More widely applied, it can help utilities meet new environmental regulations, adjust to workforce changes, and manage capital investments and operating costs. Every aspect of facility planning, design, operations, maintenance, asset management, and data management is impacted by the others, so coordinating and integrating myriad aspects of facility management is crucial (Figure 1). In a fully optimized plant, all components are working together and complementing one another for successful long-term operation.

Figure 1. Integrating all facets of planning, design, and operation can lead to optimized and reliable facility optimization (Credit: Black & Veatch)

Enhanced Operational Efficiency

The water sector continues to focus on operational efficiencies to enhance performance reliability and reduce consumption of resources such as energy and chemicals, but new directions and practices merit mention.

Selecting treatment strategies that reduce consumption of resources is a foundational opportunity to optimize a facility. Strategies that direct more organic material from wastewater toward anaerobic digestion, where it can be converted to biogas, potentially reduce the energy required for aerated biological treatment processes and provide a renewable energy source. Incorporating more resource-efficient microorganisms such as anaerobic ammonium oxidizing bacteria (anammox) into the treatment processes furthers the potential for optimization.

It’s important to consider the impacts of mechanical and electrical design choices on efficiency over the life of the facility. The design life of treatment facilities often projects 20 years or more into the future. However, equipment that is sized and selected for efficiency at a future design capacity may operate inefficiently under conditions of lower wastewater flows and loads, thus increasing energy demands relative to the level of treatment in the near term. Incorporating appropriate new processes and tools into planning and design and simultaneously considering operation and asset management for the full life of the facility is a challenging, but essential, balancing act.

Although many designers are already mindful of how designs affect future maintenance, the true costs and challenges of maintenance are often not fully realized until well after commissioning. What’s more, the results and feedback don’t always make it back to the design and planning teams. Knowledgeable engineers enhance designs by incorporating risk-management practices such as hazard-and-operability review (HAZOP) and failure modes, effects, and criticality analysis (FMECA) results into facility designs or upgrades. The quality of 3D models and building information modeling (BIM) and the ability to link equipment information can provide an intuitive way for operations and maintenance professionals to access equipment data and other information.

A membrane aerated biofilm reactor (MABR) is a promising new biological nutrient removal (BNR) technology that offers optimization opportunities through process intensification. MABRs can help utilities reduce energy costs and simultaneously increase treatment capacity and process sustainability for BNR. (Credit: Black & Veatch)

Recognizing the need for guidance on the wide range of nutrient control techniques, The Water Research Foundation in 2020 launched “Guidelines for Optimizing Nutrient Removal Plant Performance” (WRF project 4973). The resulting roadmap will help water resource recovery facilities (WRRFs) optimize nutrient removal to reduce costs, increase efficiency, and reduce nutrient discharges. Researchers have already conducted a series of webinars about optimizing existing nutrient removal facilities to improve reliability and reduce costs and discharge concentrations. The project team will incorporate operational best practices and full-scale experiences into nutrient optimization guidelines to yield a roadmap for optimized operation.

Treatment Technologies

Recent trends in optimization practices include innovations in process intensification to increase the capacity or level of treatment achieved in a given site’s footprint. Historically, owners and operators often have accomplished this through strategies that tend to increase the mechanical complexity of treatment facilities. More recently, the water sector has focused on doing so through better understanding of treatment mechanisms. Advancements in analytical methods of identifying microbial ecology and how microorganisms actually function in a given environment have substantially contributed to this enhanced understanding.

As one example, WRRF process engineers and operators are increasingly focused on optimization of performance, capacity, and space through a better understanding of biofilms. Although treatment plants in the U.S. have used biofilm processes — including trickling filters, biologically active filters, moving bed biofilm reactors, and integrated fixed-film activated sludge processes — for years, suspended growth activated sludge systems have been the mainstay. However, research and practical experience have shown that the organisms that remove pollutants from wastewater grow not only under different environmental conditions, but also at different rates. This necessitates the development and adoption of new ways to promote growth and retain slower-growing biomass in the treatment system.

The water industry is rising to this challenge by developing and commercializing processes and products to promote the growth of denser flocs or biofilm granules in activated sludge processes, applying deammonification processes using anammox biofilms in mainstream wastewater treatment, and combining an efficient aeration strategy with biofilm processes in membrane aerated biofilm reactors (MABRs). The key drivers behind this work are twofold: (1) to optimize and reduce space and costs, and (2) to optimize the use of resources. The application of MABR technology provides not only a reduction in reactor volume but also an enhanced means of delivering oxygen to microorganisms, which in turn reduces energy costs.

Under the U.S. EPA G2020-STAR-A1 program, The Water Research Foundation is managing a collaborative project team comprised of several utilities and universities to better understand the microbial ecology and establish design and operating conditions needed to apply partial denitrification/anammox (PdNA) process strategies for efficient mainstream nutrient removal (WRF project 5095, “Mainstream Deammonification with Biological Phosphorus Removal”). This process can reduce the reactor volume needed for nitrification (oxidation of ammonia to nitrite) while employing slower-growing anaerobic ammonium-oxidizing bacteria on biofilms that use both nitrite and ammonia to achieve nitrogen removal. It therefore minimizes energy consumption and the need for dosing chemicals.

Data Management And Analytics

The world has greater access to data than ever, but the water industry is still developing data collection, management, analytics, and controls to more effectively use those data to inform decision-making across all management and operational functions. Many treatment facilities have centralized supervisory control and data acquisition (SCADA) systems or distributed control systems (DCS) for plant process and equipment control. Operators monitor equipment for status and performance, with perhaps thousands of signals collected as unique data points in the control system that can be stored in a data historian. Separately, and often manually, combining key operating data such as wastewater flows with laboratory data in spreadsheet software to develop trends for process analysis can be very time consuming. As a result, much of this data is relatively untapped to support decisions that would enable higher levels of performance and control. Recent advancements that leverage business-intelligence tools offer an opportunity to save time extracting, transforming, visualizing, and analyzing data for faster and more meaningful performance monitoring.

Data management platforms that serve as a datahub using inputs/data from the SCADA or DCS, laboratory information management systems (LIMS), and computerized maintenance management systems (CMMS) enable more efficient combination of these datasets for dashboards, tracking of key performance indicators, automated reports, and saving staff time for other things. Facility-specific systems can provide real-time (or frequent) updates for management and operations staff.

Once collected and organized, advanced analytics can identify trends and predict outcomes that in turn provide opportunities to optimize the performance of equipment and processes. Utilities are also starting to incorporate digital twins for asset management and/ or wastewater processes. Advanced equipment monitoring and data analytics yield insights into equipment health and performance that maximize prioritization benefits.

Asset Management

Asset management is key for optimizing capital investments in treatment facilities. Taking care of equipment and infrastructure to ensure that it performs as required for the full design life of the facility is essential to managing cost and risk. A data-driven mindset is essential in this regard. Utilities continue to develop monitoring programs to collect the right data, populate maintenance management systems, and track and analyze data to facilitate better decisions. After implementing asset-level likelihood-of-failure and consequence-of-failure metrics, asset condition assessment procedures, and onsite condition assessment of critical assets at its largest treatment plant, the Hampton Roads Sanitation District has nearly completed the process at its other plants as well. Real-time asset management dashboards were developed to provide easy access to selected performance data at the overarching facility and asset levels. Various groups within the organization can easily harness the asset management data to inform workflow improvement, asset maintenance, replacement planning, capital planning, and regulatory compliance.

Looking outside the water industry has helped — and can continue to help — water utilities advance asset management practices for facility optimization. Development of ISO standards demonstrated the value of collaboration across industries and countries for effective asset management. There is room to learn more from manufacturing, electric, gas and oil industries, particularly with their advanced monitoring and diagnostics of asset health.

Planning

Utilities are continuously challenged to balance many demands on resources and must find ways to cost-effectively upgrade aging infrastructure and maintain high levels of service. A focus on innovation and best-value solutions is critical to making the most of assets. In a recent project, the Miami-Dade Water and Sewer Department (MDWASD) leveraged an aggressive value-engineering approach with innovative design that provided cost savings of more than $300 million for capital projects and O&M efficiency savings of $3 million annually at the county’s treatment facilities. Through a pilot program with Black & Veatch, MDWASD demonstrated that newer, less-expensive filtration technology would comply with Ocean Outfall Legislation Program’s requirements while providing significant savings. Reducing costs and nutrient discharges to the ocean optimizes resource management.

Full-Facility Optimization

Optimization is a proven way to enhance water resource recovery and sustainability. Incorporating water resource recovery processes that reduce energy, chemicals, and/or costs through initial design or subsequent improvements continues to be important, and emerging tools such as process intensification through biofilm technologies can also help communities meet new environmental regulations, adjust to workforce changes, and manage capital investments as well as operating costs. But within the water sector, there’s an overall refocus on the bigger picture as exemplified by increasing use of “One Water” and watershed management strategies. This integrated-solutions approach also applies to optimization practices and creates valuable synergy across the myriad aspects of facility management. Long-term operation is most effective when all components work together in a fully optimized facility.

About The Author

Chris deBarbadillo, PE and ABC class IV wastewater operator, is an associate vice president and plant optimization practice leader for Black & Veatch. In this role, she helps water resource recovery professionals develop and implement strategies that optimize projects at each stage of their lifecycles, from assessments and planning through technology selection, process design, and project implementation with long-term operations in mind

Chris deBarbadillo, PE and ABC class IV wastewater operator, is an associate vice president and plant optimization practice leader for Black & Veatch. In this role, she helps water resource recovery professionals develop and implement strategies that optimize projects at each stage of their lifecycles, from assessments and planning through technology selection, process design, and project implementation with long-term operations in mind