Reducing Water Waste And Increasing Reuse With Remote Monitoring And Control

By Marco Achilea

Now more than ever, it’s time to explore circular water management solutions to prevent loss of the world’s most valuable resource.

According to the World Economic Forum’s Global Risks Report (GRR), water was a significant factor in conflict in at least 45 countries around the world in 2017. The report also highlights water scarcity as one of the top five risks for the world, a spot it has held for eight consecutive years.

For the United Nations (UN), water is a core element of its Sustainable Development Goals (SDGs), with SDG 6 promising access to clean water and sanitation for all. According to the UN, water scarcity, poor water quality, and inadequate sanitation negatively impact food security, livelihood choices, and educational opportunities for poor families across the world. Currently, more than two billion people are living with the risk of reduced access to water resources; and by 2050, at least one in four people is likely to live in a country affected by chronic or recurring water shortages.

It is against this backdrop that operators of water networks are striving to reduce waste and increase operational efficiency, with the end goal of making water part of the circular economy.

This scenario has increased the focus on automation and the role that it, along with the increasing influence of smart intelligent devices, can play in the management of this scarce resource. We see much of the attention concentrating on minimizing the loss of potable water, but also to increase the utilization of treated water. That all must be set against the fact that, traditionally, the water sector has been extremely conservative both in processes and its adoption of technology. The adoption of automation and the sector’s investment in the technology has been slower than many others, such as oil and gas, power, or even the process industries. As a result, many sites today have minimal automation, a situation that is increasing the pressure on operators to modernize.

A couple of examples of this include the growing number of desalination plants that are now concentrating on reducing the high energy use that is traditional with that process, and wastewater plants that need to reduce the release of the water while increasing its availability for irrigation or to put back into the water cycle for humans. These challenges are pushing the sector to rethink the way that they operate, and the consequence is that there is an increasing demand for more automation and control in the sector. In general, requests for automation and control are becoming more and more sophisticated in terms of automation and control, with remote monitoring moving higher up the wish list. In effect, they are becoming more network-focused with increased communications. In the past, the facilities were not operating in a connected manner. The trend now is that more assets are becoming connected, which is enabling remote monitoring in a big way.

The Facilitators

Another important element here is people. Like most industrial sectors, the water industry is suffering from a skills shortage, and the ability to remotely monitor assets is looking increasingly attractive. It allows them to run their operation in a different way and consolidate the availability of skilled resources, with one expert not only taking care of the location where he or she is based, but also other connected sites across the network. Then there is also the change to an operator’s business model with intelligent systems that can provide data from which they can extract valuable insights into how to run the operation in a more efficient way.

When it comes to remote monitoring, pumping stations are a key element given their high energy use. With the ability to remotely monitor and control geographically spread pumping stations, these networks can be operated more efficiently. Operators want to be able to manage pumps in their network in a harmonized manner. Currently, a series of pumps can be operated on the same network with visibility over the entire operation and supervision by a control system that allows remote operation, allowing the ability to shut some down or run some at reduced capacity while maintaining optimum performance.

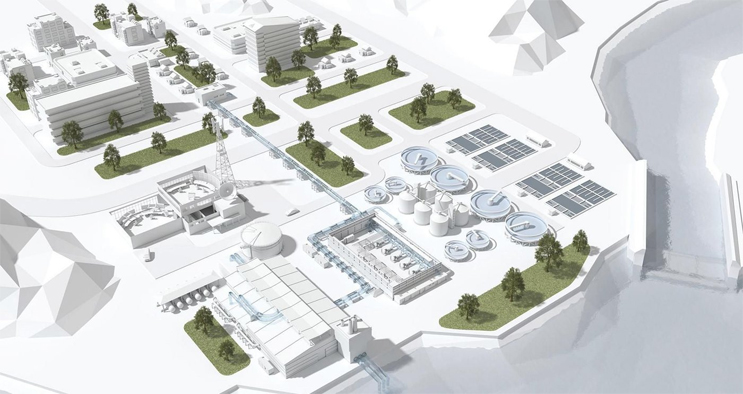

But it goes beyond that. Some utilities are trying to connect their entire networks for remote monitoring and control. This could include pumping stations, water treatment plants, and the distribution network. Clearly, the advent of the Industrial Internet of Things (IIoT) and smart sensors in more and more places on the network are of great assistance in this aim of real-time visibility and control.

Today, the backbone of all these new initiatives is still the SCADA system, although boosted by several smart applications on top. The water industry has been a big user of SCADA systems, but what is different today is that we now have the technology and expertise to collect, aggregate, and analyze more data, which will help us to increase productivity and availability.

In terms of technology, the right mix includes local intelligence devices based on IIoT technology, together with a telecommunication network for distance communication, using a very cost-driven protocol that will allow the customer to operate a remotely connected network without a huge investment compared to the past. ABB Ability™ is an example of a packaged solution that allows the customer to operate in that manner. Although it is cloud-based, it has the flexibility to allow some local computation and intelligence for customers who are not ready to fully embrace the cloud.

But we can also look beyond this visibility of a single network to a future where this extends across a series of networks, creating a network of networks. Traditionally, each single network has operated as a closed loop, but in this age of water scarcity, there is a drive to connect networks and allow water and services to flow to where they are most needed. This will also move the water sector closer to delivering a circular economy model where utilities deliver fresh water, collect wastewater, treat it, and then deliver it back to the population. If we want more accurate water usage in the future, we cannot afford the risk of wasting water — and monitoring solutions are key to this aim.

The Challenges

Although the technology is tried and tested and ready for deployment, there are still some challenges when it comes to implementing remote monitoring solutions. Along with increased visibility, driven by the growth of IIoT sensors, there is proliferation of data. Aside from collecting and storing the huge amount of data collected from disparate sources and operating systems, it needs to be harmonized into a common format before we can analyze it to deliver the vital insights needed to drive decision-making.

Another challenge is the process of extracting value and meaning from the realms of synchronized data, and this is where data scientists and data analysts play a very important role.

The final challenge that operators face is the internal network itself. Even when you have collected the data from the field, cleaned it, and allowed the data scientist to work on it, there remains the task of linking this information higher up the company’s IT infrastructure and pulling in information from the enterprise resource planning (ERP) system. You cannot have a stand-alone application today within your technological landscape, so the companies that best manage this internal integration will be the ones that are most successful.

This is not all theoretical — it is something that can be achieved immediately. In one such project, ABB is working with the rural water and sanitation department in Karnataka, India to deliver a multistage water supply scheme for two villages. In this solution, we are linking the different parts of a water scheme into one project, including pumping stations, water treatment, and water distribution. Located in a rural district with scarce water resources onsite, the project will bring more and higher-quality water for human and agricultural use, while reducing water losses. The single solution includes SCADA, programmable logic controller (PLC), and General Packet Radio Service (GPRS) across the three different applications. This will give the utility increased availability of drinking water for villagers, improved water quality via treatment and remote monitoring, and decreased water loss.

As water becomes scarcer and a greater premium is placed on reducing waste and increasing reuse, this type of system will become the norm for moving our water supply into the age of remote monitoring and control.

About The Author

Marco Achilea leads ABB Energy Industries’ water business as the water and infrastructure segment manager responsible for global strategy development and roll-out of solutions spanning water treatment, wastewater treatment, cyclical water management, irrigation, desalination, coastal and flood protection, and pumping, transfer, and distribution systems. With over 15 years of industry experience across power and water markets, he has in-depth knowledge of supply chain management, leading operations and holding responsibility for product development, market deployment, and growth. Achilea has a degree in economics and master’s in supply chain management.

Marco Achilea leads ABB Energy Industries’ water business as the water and infrastructure segment manager responsible for global strategy development and roll-out of solutions spanning water treatment, wastewater treatment, cyclical water management, irrigation, desalination, coastal and flood protection, and pumping, transfer, and distribution systems. With over 15 years of industry experience across power and water markets, he has in-depth knowledge of supply chain management, leading operations and holding responsibility for product development, market deployment, and growth. Achilea has a degree in economics and master’s in supply chain management.