Rebuilding American Infrastructure: Utilizing Lifecycle Data To Evaluate The Environmental Impact Of Piping Systems

By Tad Radzinski

In 2017, America's aging piping infrastructure, corroded piping systems, and water quality concerns are at the forefront. Examples like Flint, MI, have engineers and policymakers working to design piping systems that excel in longevity, durability, and cost-effectiveness. The controversy and magnitude of this national problem has resulted in many false claims and complicated solutions from competing piping manufacturers, leaving engineers and municipalities unsure of what solution will work best for their infrastructure needs.

Throughout North America, many infrastructure standards and building codes are now integrating lifecycle thinking into guidelines and specifications, asking the question, what is the true impact of the products we use to build our nation? When analyzing water piping systems, we ask the same question: What are the environment and cost impacts over the entire lifecycle of the piping system? Lifecycle thinking is considering all stages of a product’s lifecycle — from raw materials to end-of-life disposal — in order to fully comprehend a product’s environmental impact. In our “take-make-waste” society, we do not often consider the impacts of the materials we use in day-to-day life, nor the costs associated with resource extraction, energy use over the life of the system, disposal, water pollution, or emissions. Understanding the lifecycle impacts of a product can help design teams to identify sustainability and cost goals; spot problems and solutions that may have gone unnoticed; and design the piping system that fits the specific needs of the community.

Sustainable Solution Corporation’s (SSC) recent report, the Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials, is the first comprehensive environmental review of underground piping systems in North America. Using lifecycle assessment methodology which was critically reviewed by an independent third-party panel of experts, the report examines the long-term environmental impacts of alternative piping systems. This report asks the reader to consider the long-term impacts of our water infrastructure, and use lifecycle thinking as a tool to view piping cost, environmental impacts, and health data through a new lens.

Background: An Independent Review

SSC was commissioned by the Uni-Bell PVC Pipe Association (Uni-Bell) to conduct an independent, industry-wide lifecycle assessment (LCA) of polyvinyl chloride (PVC) pipe and to review publicly available lifecycle data of all alternative piping materials. In order to remain independent, the LCA references recognized resources and studies, underwent a third-party review, and adheres to internationally-accepted standards.

The final LCA utilizes a 100-year service life to study PVC pipe according to lifecycle assessment standards ISO 14040-series, covering commonly used PVC pipes for drinking water, sanitary sewer, and storm sewer piping within the 4” to 60” rigid PVC pipe market. This study is representative of PVC pipe manufactured in the U.S. and Canada, which uses a tin-based stabilizer and does not contain phthalates, lead, or cadmium.

The corresponding report references the data provided in this LCA to provide a comparative review of alternative pipe products, based on over 200 publicly available sources of statistical and environmental data.

Identifying a Sustainable Piping Product

A sustainable piping system is not just easier on the environment, it will generate cost savings over its lifecycle, and provide community and health benefits. By examining all potential impacts of a system over its lifetime, we can identify key value areas. According to the report, a sustainable piping system should encompass the following attributes:

- Low initial and operating costs

- Longevity, with a service life of at least 100 years

- Low pumping energy over the lifetime

- Corrosion resistance (no additional materials or costs required)

- Low maintenance

- Low embodied energy

- Minimum waste during manufacturing

- Sustainable manufacturing practices

- Minimal installation costs

- Minimal transportation impacts

- Recyclability at end of life

- Consistent high water quality without chemical additives

- No infiltration or exfiltration

When designing a piping system for your community, these characteristics can be your checklist. What type of piping system will help you to meet most, or all, of these points? Work with your supplier to answer these questions, conduct your own research, and seek out lifecycle data to assist you in making these decisions.

Look Inside: Examining the Data

The report seeks to examine the above characteristics, including performance, health and safety, and sustainability attributes of pipe materials in North America. Specifically, SSC examined characteristics of a piping system such as service life, friction factor, manufacturing impacts, and chemicals leaching into water systems; some areas of importance are described below.

Raw materials and manufacturing

As part of lifecycle thinking, it is important to evaluate all raw materials used in the manufacturing process of the product and related impacts, such as: energy use, water use, waste generation, emissions, and more. While a single attribute such as recycled content can contribute to a reduction in environmental impact, this may not tell the whole story. In the case of piping, some metal materials in fact require significant amounts of energy to recycle and emit additional toxins during manufacturing; therefore, in some cases, processing surpasses alternatives in terms of environmental impact. In comparison, PVC pipe manufacturing is a considerably low-impact process, requiring low inputs of energy and water. Closed-loop water systems and scrap reuse in the manufacturing process additionally contribute to lowered manufacturing impacts. The report found that even when using virgin materials, the manufacturing impact of PVC pipe was less than that of alternative materials. By examining the manufacturing impacts of a product as a whole, rather than focusing on one sustainable attribute, engineers can develop systems that meet their sustainability goals.

Longevity

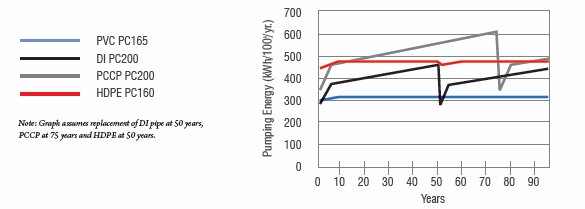

Longevity is of key importance when considering piping systems; in part due to frequent breakages in our aging water and sewer infrastructure. With 850 breaks per day in the U.S., and 300,000 breaks annually, leaking pipes are responsible for the loss of more than 2.6 trillion gallons of treated drinking water each year, or 17 percent of all water pumped in the country (United States Conference of Mayors, Municipal Procurement: Procurement Process Improvements Yield Cost-Effective Public Benefits, March 2013). When considering lifecycle impacts of pipe, it is necessary to consider the impacts of corrosion and the replacement of pipe. In the figure below, we see the estimated lifetime of various piping systems and related energy consumption.

As shown above, the service life of PVC pipe is expected to exceed 100 years, with Ductile Iron, PCCP, and HDPE pipe requiring replacement within the same time frame. Since PVC pipe does not require replacement during the 100-year design life, it eliminates traffic costs; related construction; environmental impacts of excavation and installation; as well as other lost revenue associated with pipe replacements.

Low pumping energy over lifetime

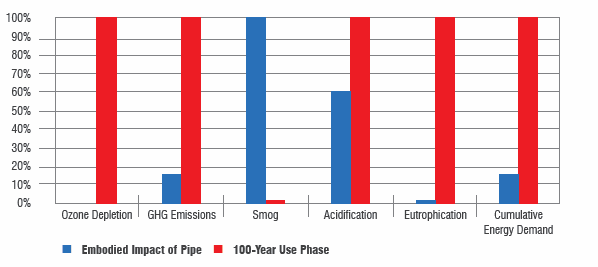

Four percent of all U.S. electricity is consumed for water distribution, representing 80 percent of municipal water processing and distribution costs (University of Michigan Center for Sustainable Systems, U.S. Water Supply and Distribution Factsheet, August 2016). This represents a significant opportunity for municipalities to reduce costs and environmental impact. The figure below shows that for PVC pipe, like all other piping systems, the environmental impacts of the use phase far outweigh the impacts associated with the cradle-to-gate impacts in almost all categories. With this understanding, it is critical to understand the differing use-phase energy impacts of alternative piping materials. Based on research and evidence from dig-up studies, the energy required to pump water through PVC pipe over a 100-year design life remains constant because PVC pipe walls are smooth, and do not roughen over time. When compared to piping materials that corrode internally, and therefore require additional energy for pumping through a smaller space, PVC pipe generates overall lifecycle cost savings and a lower carbon footprint.

Planning for the Next Decade

Based on the results of this study, PVC pipe provides both environmental and economic advantages to meeting the water infrastructure goals set by municipalities and communities. Using a lifecycle approach when compared to alternatives, PVC pipe exhibits reduced environmental impacts from a lifecycle and carbon footprint perspective, resulting in additional cost savings for municipalities.

Engineers, municipal officials, and other stakeholders need to integrate and utilize lifecycle thinking when considering the costing, environmental impacts, and the longevity of water infrastructure when making piping decisions. These decisions will impact first cost and operating costs, lifetime energy consumption, and greenhouse gases for the life of the piping system. Again we ask the question — what is the true cost and impact of the products we use to build our nation?

For more information on the results of this study, or to download the Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials, visit our website at: http://sustainablesolutionscorporation.com/papers.html

About Tad Radzinski

With over 30 years of practical experience, Tad Radzinski is a leading expert in corporate responsibility and environmental management. Tad, co-founder and president of Sustainable Solutions Corporation, delivers consultative services to companies in a wide range of global industries. Additionally, Tad is co-founder of, and Certification Officer at, GreenCircle Certified, LLC, providing third-party verification of environmental claims and ensuring transparency in the green marketplace. Formerly the EPA’s Waste Minimization Program National Expert, Tad has been a trusted advisor for Fortune 500 companies including ASSA ABLOY, Merck, Saint-Gobain, and Kohler. www.sustainablesolutionscorporation.com