PART II: How do you install fiber optic lines via your sewer system?

Part I told how a telecommunications attorney came up with the idea to utilize aging sewer lines as the conduit for new cable lines. Not only does it eliminate the problems of excavation when laying a line but the leasing of the sewer lines provides badly needed renovation revenue. Today's installment talks about the actual technology in detail.

By Jey K. Jeyapalan, P.E., Ph.D.

Pipeline Engineering Consultant

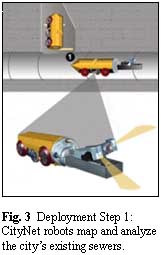

CityNet, a company pioneering the concept of using sewer lines as a conduit for fiber optic cable, uses a small computer-driven robot, called a Sewer Access Module (SAM) equipped with CCTV cameras, as shown in Fig. 1, to install alloy rings to support the fiber optic cables inside of the sewer pipes.

Up to 9 fiber optic cables in alloy conduits can be installed side by side in a sewer system. These cables are of either 216 fibers, arranged in 9 bundles of 24 each, 144 fibers, arranged in 6 bundles of 24 each or 72 fibers arranged in 6 bundles with 12 fibers in each.

Each of these fibers is about 150 microns in diameter, a mere 50% thicker than a human hair shown in Fig. 2, transmitting data at the speed of 300,000 km/sec at multiple wavelengths using either DWDM or WDM technology.

The outer diameter of these bundled cables in protective conduits measures 11.5 to 15.5mm. The planning of the work commences with a CCTV inspection of the sewer line, and reporting as shown in Fig. 3.

All maintenance work needed is carried out at the onset before installing any cables. In the next step, the clamps are installed in the sewer by using the robot as shown in Fig. 4.

The clamps are loaded into a magazine that is attached to the robot, which then travels through the sewer, using a laser guide to precisely place each ring in its prescribed location within the sewer -- approximately 1.5m apart.

After supporting rings installed, robot comes back to get conduit

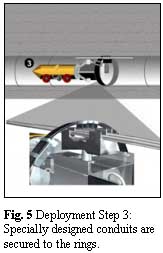

Once all the rings are placed, SAM crawls back out of the sewer and fitted with another head, transports the conduit through the sewer as shown in Fig. 5.

Once again using the laser guides, SAM fastens the inner duct to the clips, locking it securely in place. Using high-pressure air, the cable is blown through the inner duct as shown in Fig. 6, and terminated to a patch panel for use by carrier customers.

Using this technique, the existing sewer pipe structural integrity remains unscathed. As a matter of fact, the rings of cross-sectional thickness less than 1mm deployed at 1.5m centers act as a reinforcing skeleton, increasing the load carrying capacity of the aging sewer pipe, while taking up less than 1% of the flow capacity of the sewer in most cases.

Man- entry sewer pipes with a diameter of 800mm and above are equipped using a sled system with clip holders bolted to the inside sewer wall, at a distance of 1.5m. To mount the expansion bolt, a hole must be drilled into the sewer wall, which poses no major structural problems due to the adequate wall thickness in sewers with a 800mm dia. and above. Similar to the installation in non-man entry sewers, protective conduits carrying fiber optic cables are fastened to the clip holders.

Sewer inspections and maintenance can resume as before

Sewer inspections by means of CCTV robots can be carried out as before. Sewer cleaning can be done as usual with high-pressure washing without disturbing fiber optic installations. Inspections proved that no grit collected at the installed components.

Operation can continue in same manner, too

Sewer systems equipped with CityNet's technology can be maintained by a number of standard trenchless rehab methods. The operation of the sewer system can be continued in the usual fashion. Leak tests such as smoke testing can be carried out without major problems. The sewer owner is able to generate additional revenue from the lease of the underground sewer network while adding value to the buildings in the city that now have access to end-to-end fiber optic connectivity. Cost is minimal due to the use of robots to install the cables. Because fiber optic cables and components are housed in the sewer network for a design life of 25 years, CityNet takes responsibility to inspect and maintain the sewer network for the city while sharing in the revenue.

It's a win-win situation for all concerned

The in-sewer deployment offers a win-win situation for all parties involved. For telecom carriers and network service providers, it's a true, end-to-end last-mile fiber optic network, which they control. For cities, it's a unique and powerful economic development tool, added revenue from an existing infrastructure, and of course protection from damage to roads and disruptions to traffic.

For building owners, it provides a major upgrade for their buildings for free, and in turn brings extra value to the buildings. Finally the promises of 1996 are coming to pass. Access will be available without disrupting other activities. Carriers, both incumbent and competitive will be able to deliver on their promises of lower rates, higher speeds and better service. The last mile instead of being slow and painful with barriers and potholes will become a smooth ride.

For more information, contact jkjeyapalan@earthlink.net

Edited by Joyce Everhart

Content Manager, Public Works Online

jeverhart@vertical.net