Overcoming Operations Challenges For Direct Potable Reuse

By Justin Mattingly

The Water Environment & Reuse Foundation introduces a “bundle of research” to help direct potable reuse and its practitioners reach full potential.

As communities in water-stressed regions look to pursue new and more sustainable water supplies, direct potable reuse (DPR) is expected to become an increasingly common option. DPR is the introduction of advanced treated water from a wastewater treatment facility directly into a drinking water treatment facility or distribution system without the use of an environmental buffer. The advanced treatment used in a DPR system will include processes such as reverse osmosis (RO) that are largely uncommon in conventional wastewater and drinking water facilities. Understanding how to manage these processes is a critical component for making DPR a reality.

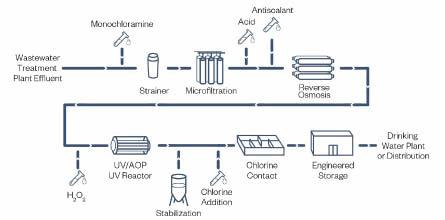

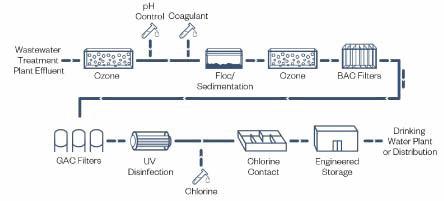

Recent research from the Water Environment & Reuse Foundation (WE&RF), led by Troy Walker and Dr. Ben Stanford of Hazen and Sawyer, breaks down the treatment trains expected to be part of DPR systems to identify the operational points of most importance, as well as strategies for effective maintenance (see below). This research is part of WE&RF’s Direct Potable Reuse Initiative aimed at supporting efforts in California and elsewhere to advance DPR.

Safety First: Ensuring Water Quality

The first project in this bundle of research, Critical Control Point Assessment to Quantify Robustness and Reliability of Multiple Treatment Barriers of a DPR Scheme (Reuse-13-03), used the hazard analysis and critical control point (HACCP) method to identify the critical control points (CCPs) of two advanced treatment trains for DPR. Originally developed by the food industry, the HACCP method is a means of controlling microbial hazards. It is used to develop operational controls to detect and correct deviations in quality at the earliest possible opportunity before a health hazard occurs, which is accomplished through a focus on monitoring and maintaining the barriers of treatment, rather than on end-of-pipe sampling and testing.

RO-based treatment train

For this research, a CCP is a point in a treatment process whereby controls to reduce, prevent, or eliminate process failure can be applied, and whereby monitoring is conducted to confirm that the control point is functioning correctly. The ozone-biological activated carbon (BAC) based treatment train is an example. Initially, BAC could not be considered a CCP because there was no control mechanism to adjust its ability to achieve pathogen reduction or contaminant removal. Yet, by modifying the process to incorporate a coagulation step ahead of filtration, BAC became a control point. BAC effectively reduced turbidity and hence levels of microorganism removal if operated as a biological filter. The HACCP method facilitated this decision, although it was straightforward from a process design and selection viewpoint.

On top of identifying the CCPs in DPR treatment trains, the robustness of those treatment processes was also evaluated. The researchers conducted a Monte Carlo simulation with full-scale data to model contaminant removals across the multiple barriers for both treatment trains studied. The two treatment trains exceeded the current California regulations for groundwater injection of 12-log removal of viruses, 10-log removal of Cryptosporidium, and 10-log removal of Giardia, the results confirmed. The only exception was removal of Cryptosporidium in ozone-BAC treatment. However, the processes in that treatment train could be further optimized within a specific facility to reach the removal targets. This research is clear in its determination that non-RO based treatment is adequate for removal of Cryptosporidium, bringing DPR another step closer to reality in many communities.

Ozone-BAC treatment train

A third element of this research explored the reliability of monitoring systems for advanced treatment processes. Where there is risk that a critical process may fail, monitoring needs to be in place to inform operators of needed adjustments. The reliability of these monitors is a critical component of a DPR system to ensure that operators are aware of process upsets, ensuring that public health is not at risk. The results indicated that trace organic compound (TOC) analyzers have the highest risk for failure to measure the true value. It is notable that the TOC analyzers seem to have the highest risk of failure to provide an accurate measurement, but the disinfection processes and associated monitors had the greatest impact on potential risk. This is important, as it can help identify where calibration and verification need to be high-priority functions, and it may indicate where redundant monitors may provide additional security.

Ops Detail: Ensuring Operator Know-How

The second research project in this bundle, Development of Operation and Maintenance Plan and Training and Certification Framework for Direct Potable Reuse Systems (Reuse-13-13), looked at O&M protocols in DPR systems as well as operator training and certification programs. As previously mentioned, unlike conventional wastewater and drinking water treatment facilities, DPR facilities deploy a greater variety of advanced treatment processes. Because of greater public scrutiny of DPR, operators will have different requirements for performance, thereby necessitating the need for comprehensive training and operations procedures. To develop this operational framework, the researchers first completed a gap analysis to determine the important operational and maintenance requirements for integration into a permitting structure for DPR. They focused on California.

In California, current permitting practices for water reuse contain regulations regarding cross-connection control and backflow prevention to prevent contamination of potable water systems from wastewater and recycled water systems. The need for this is obvious, but because DPR purposely creates a link between recycled water and drinking water systems, changes are necessary. To help mitigate potential risks from this change, strong O&M safeguards need to be in place. Additionally, there will likely need to be modifications to source control programs to accommodate more impaired water sources, staffing and operator certifications, and monitoring and reporting requirements. In addition, while current regulations in California do not specifically address DPR, the California State Water Resources Control Board has released a final report stating that it is feasible to develop regulations for DPR. As California moves forward with criteria for these regulations, issues in O&M are expected to be addressed.

With the HACCP system already defined, the O&M framework developed in this second project takes the next step to define further the key elements required for successful operation. The elements include:

- integrating CCP monitoring parameters into SCADA systems,

- alert and alarm levels that trigger specific response procedures,

- assessment management practices to properly manage assets and protect the CCPs of a treatment train, and

- a DPR operations plan with

- elements of occupational health and safety for operators,

- recruitment and training of qualified staff, and

- emergency management.

Case studies are also included in the final research report as examples of actual facilities that utilize advanced treatment processes.

The last element of this research is a recommended operator training and certification framework for DPR. Current certification programs typically target wastewater operators and drinking water operators. However, because DPR has elements of both wastewater and drinking water, operators in advanced treatment facilities do not explicitly fall into either category. In California, the focus of existing certification programs is on conventional wastewater and drinking water treatment trains. While this will be important for DPR operators, the programs do not address advanced treatment technologies such as membrane treatment or ozone in depth. There is certification in California for nonpotable water reuse, but it exists as a subset to wastewater requirements, and there are significant gaps. Having training on advanced treatment processes available to operators will help overcome these gaps and further facilitate implementation of DPR.

For most existing indirect potable reuse facilities that employ advanced treatment processes, facilities have operators with a combination of wastewater and drinking water certifications along with supplemental training provided for specific processes. For example, the Orange County Water District in California requires operators to have wastewater treatment certifications along with additional training in membrane and advanced oxidation processes. This approach may work in large utilities that have the capacity to train operators properly themselves, but smaller utilities or those with fewer resources may not be able to do so. The research report provides an assessment of operator certification and training needs for DPR using examples from throughout the U.S. and Australia.

In anticipation of a need for qualified DPR facility operators, the California-Nevada section of the American Water Works Association is working with a broad coalition — including WE&RF — to develop a new certification program for advanced water treatment. This new program will include advanced treatment processes and help ensure operation of DPR facilities to a high standard, which consistently protects public health. In addition, WE&RF has new research underway with the Hazen & Sawyer team, along with the Santa Clara Valley Water District and other stakeholders, to develop DPR operator curriculum and training materials for utilities, educational institutions, and other interested organizations. When combined with our vast portfolio of completed, ongoing, and planned research on DPR, WE&RF will be at the forefront of the effort to ensure that DPR becomes a sustainable, reliable, and safe source of drinking water for communities nationwide.

About The Author

Justin Mattingly is a research manager at the WE&RF focused on treatment systems for potable reuse, industrial reuse, and water economics and finance. Prior to joining WE&RF, he completed a four-year fellowship at the U.S. EPA in the Clean Water State Revolving Fund program, working with states and communities to develop innovative financing tools and strategies to fund a diverse array of water quality projects. During this time he also focused on stormwater management and combined sewer overflows, helping communities develop management plans and financing programs to promote the use of green infrastructure. In his current role at WE&RF, Justin has presented at multiple conferences, authored several papers and articles, and participated on several working groups and advisory committees related to water reuse. He is also engaged with decision makers at the state and federal level to overcome the regulatory and financial barriers related to water reuse. Justin graduated from the University of Delaware with a Bachelor’s degree in Biological Sciences and a Master’s degree in Environmental Science from American University.

Justin Mattingly is a research manager at the WE&RF focused on treatment systems for potable reuse, industrial reuse, and water economics and finance. Prior to joining WE&RF, he completed a four-year fellowship at the U.S. EPA in the Clean Water State Revolving Fund program, working with states and communities to develop innovative financing tools and strategies to fund a diverse array of water quality projects. During this time he also focused on stormwater management and combined sewer overflows, helping communities develop management plans and financing programs to promote the use of green infrastructure. In his current role at WE&RF, Justin has presented at multiple conferences, authored several papers and articles, and participated on several working groups and advisory committees related to water reuse. He is also engaged with decision makers at the state and federal level to overcome the regulatory and financial barriers related to water reuse. Justin graduated from the University of Delaware with a Bachelor’s degree in Biological Sciences and a Master’s degree in Environmental Science from American University.