4 OSHA Changes To Be Aware Of In 2015

The utility sector mirrors what happens with the general industry and construction sectors throughout America. The field personnel conduct trenching, excavations, even erecting structures on a regular basis. Plant personnel are exposed to chemical, biological hazards, and many other hazards that can cause injury or illnesses. OSHA, the Occupational Safety and Health Administration, is the regulatory body that has jurisdiction to guide the employers in ways to protect the employees.

However, only states that have their own approved OSHA program can regulate public water and wastewater utilities. Each state plan must be as strict as or more stringent than the federal OSHA as a term of their program approval. In addition, the state programs must adopt the federal OSHA regulations within six months for the final ruling in the Federal Register. This article will highlight four key regulatory changes or pending changes in 2015.

According to OSHA’s Unified Agenda, there are three stages for rules to become law:

- Pre-Rule

- Emergency Response and Preparedness

- Communication Towers

- Proposed Rule

- Cranes and Derricks in Construction: Operator Certification

- Occupational Exposure to Crystalline Silica

- Final Rule

- Improve Tracking of Workplace Injuries and Illnesses

- Confined Spaces in Construction

Recordkeeping requires the employer to denote workplace injuries, illnesses, catastrophes, or fatalities within a certain timeframe. After January 1, 2015, a catastrophe will be one hospitalization instead of three, which has been modified. Once the worker is admitted to the hospital, OSHA has to be notified within 24 hours of the hospitalization. In addition, any amputation or loss of an eye must be reported to the OSHA office within 24 hours. A workplace fatality must be reported no later than eight hours of notification.

The utility can report to OSHA by:

- 1-800-321-OSHA (6742)

- Calling the closest OSHA Area Office

- Use the upcoming online form

Process Safety Management (PSM)

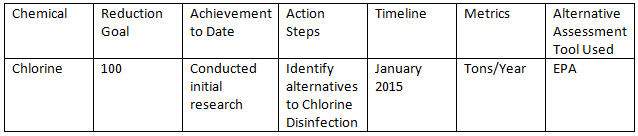

OSHA has been making a push to get companies to switch from highly hazardous chemicals to safer alternatives. This switch will help reduce the exposure to chemical hazards to the workers and the community. Liquid utilities have to disinfect with chemicals in a large quantity, therefore, several are under the Process Safety Management program or the EPA Risk Management Program. There is a guidance electronic tool (e-tool) provided by OSHA that gives seven steps transition to safer chemicals. These steps are:

- Engage

- Develop a team to outline a plan with achievable goal and milestones to the transition.

- Include engineering, service workers, maintenance, operators, laboratory personnel, and any applicable stakeholder.

- Develop a work plan (OSHA sample work plan model used below).

- Inventory and Prioritize

- Evaluate your current chemical use.

- Prioritize what chemical is the greatest concern for the utility.

- Do an inventory to date to ascertain how much product must be replaced and in what timeframe.

- Identify

- Look for all possible chemical alternative that will be as effective as or more effective than the target chemical.

- Make sure to check with NPDES permit issuers for regulatory guidance on alternatives.

- Look for all possible chemical alternative that will be as effective as or more effective than the target chemical.

- Assess and Compare

- Be aware of the hazards associated with the alternative chemical.

- Know how to protect the workers from the new hazards, if any, in accordance to regulatory requirements.

- Select

- Continue to assess the pros and cons of each alternative, but select one after the analysis.

- The EPA has a design for alternative assessments for chemicals to help the utility in this quest.

- Test

- Do a small and large-scale test to make sure the anticipated result matches the actual performance.

- Consider a job hazard analysis for the handling and use of the new chemical to identify and select protection for each stage of the tasks.

- Evaluate

- Did the alternative chemical work as well as you wanted?

- Keep tracking performance to verify effectiveness.

- Share your results with fellow utilities.

Fall Protection for General Industry

Falls in constructions is a known hazard that is addressed in OSHA’s Focus 4 (the four leading causes of death) initiative. The construction standard, 29 CFR 1926, even has Subpart M, which is expressly for Fall Protection. However, the General Industry standard 29 CFR 1910, there are sporadic mentions of fall protection. Falls to lower levels can end tragically, but there are not standards to cite when a general industry worker is maintaining a building at an elevated height. A simple task of changing a windsock on a steep pitched roof would not violate a specific standard except the General Duty Clause in 5A1 of the OSH Act of 1970 that states in part that an employer must furnish a place of employment free from any known or suspected hazards.

In the Unified Agenda, OSHA has a final rule on the revision of the Walking Working Surfaces and Personal Fall Protection System (Slips, Trips, and Fall Prevention). However, this final rule for this 29 CFR 1910 revision to Subpart D (Walking Working Surface) and Subpart I (Personal Protective Equipment) has been pending since May 2010. If 2015 were the year that the fall protection for general industry passes, then the utilities would have an additional regulation to be aware of and comply. Training on compliance requirements and additional PPE will be needed by the utility.

Confined Space Entry for Construction

Confined Space is defined:

- as any space that a worker can get into and perform assigned work; and

- it is not meant for continuous human occupation; and

- has limited access and egress

When a confined space has a hazard present such as electrical, atmospheric, configuration, etc., then it becomes a permit-required confined space. The permitting process is in-house, but it takes account of the situation, entrants responsibilities, attendee responsibility, and how to protect the worker from the hazard that is present.

In construction, excavations meet the definition of a confined space; therefore, the workers must be protected in the same manner as general industry. OSHA has made the final rule for this change, so now the utility must adjust and train workers as to how to protect themselves.

Although, this article only highlighted four occupational safety concerns and future and/or current regulations, the utility must remain vigilant to protect the workers from injury and illnesses. As always, protecting the workers is a high priority with each public sector throughout the U.S.