Odor And Corrosion Control For Sewage Lines, Pump Stations, And Collection Systems

The Gener-Ox LS process is a chemical-free technology that addresses the root cause of H2S odor and corrosion problems in sewage transport. The process is completed by converting sewage flow from anaerobic to an aerobic biology.

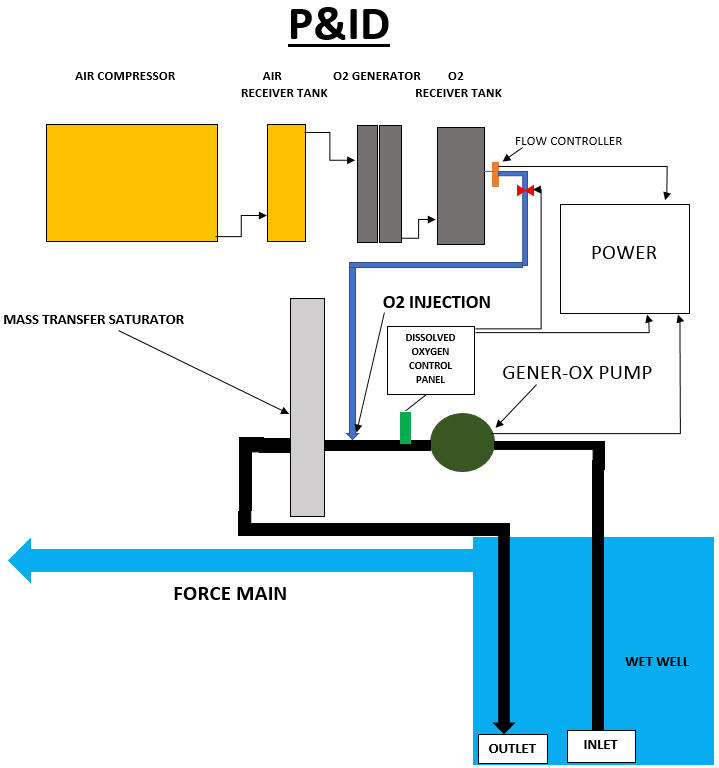

The Gener-Ox LS system draws a side-stream of sewage water from a pump station wet well, pressurizing the sewage flow while simultaneously aerating with on-site generated high purity oxygen. Under the pressure and flow conditions of the process, gas phase oxygen is driven into solution to achieve a desired dissolved oxygen (DO) concentration. This oxygenated flow is then reinjected to the wet well to continuously maintain aerobic conditions in the wet well. The Gener-Ox LS system is placed on one skid, with the option to be single phase or three phase power. The oxygen injection is controlled by a dissolved oxygen sensor and introduces oxygen only when the dissolved oxygen levels fall below a pre-determined set point.

Piping and instrumentation diagram (P&ID) for the Gener-Ox LS

About Gener-Ox, Inc.

Gener-Ox, Inc. was formed for the primary goal of developing chemical-free technologies to minimize the occurrence of odor and corrosion in wastewater lines, pump stations, collection systems, and land irrigation systems. IER’s odor control team offer a combined 75 years of experience in water and wastewater treatment. Our mission in sewage treatment is very simple: Minimize the use of industrial chemicals while maximizing solutions that originate from nature. For more information, visit www.inlande.com/generox.htm or email Joe Hennessy, Product Manager, at Jhennessy@inlande.com.Jhennessy@inlande.com.

Source: Gener-Ox, Inc. Oxygenation Systems