New Solids Separation System Prevents Lift Station Blockages

Thomasville, GA — EMUPORT Packaged Lift Stations—currently available from WILO EMU USA LLC—are now available with an integral solids separation system. This robust system effectively prevents lift station blockages including systems with a high percentage solid content. This includes sewage containing material that will not dissolve and keeps it original form and structure i.e. cellulose towels, sheets and other fibrous or non-dissolving items.

Thomasville, GA — EMUPORT Packaged Lift Stations—currently available from WILO EMU USA LLC—are now available with an integral solids separation system. This robust system effectively prevents lift station blockages including systems with a high percentage solid content. This includes sewage containing material that will not dissolve and keeps it original form and structure i.e. cellulose towels, sheets and other fibrous or non-dissolving items.

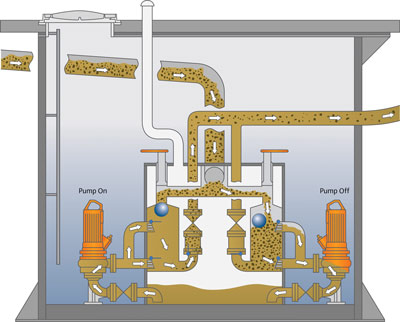

EMUPORT Packaged Lift Stations are available for wet pit and dry pit applications; however, the EMUPORT Solids Separation System is a dry pit design and allows pumps to be maintained without contact with the sewage and can be installed either above or below ground.

The EMUPORT Solids Separation System allows sewage to flow into a primary collection chamber where the solid content of the sewage is held back.

During the filling sequence the pump is inactive and solids are held back by a screen in the solids separation reservoir—only the smaller sewage particles (1") and the liquid flow into the main collection chamber. When the main collection reservoir is full, the pump is then activated by a series of level controls and the flow of the filtered sewage is pumped back through the solids separation reservoir, agitating the collected solids in the separation reservoir and pumping them into the out going force main.

This means that the major solid particles never come into contact with the pump, but are still moved and pumped into the discharge pipeline efficiently.

The use of an EMUPORT Solids Separation System allows WILO-EMU to utilize smaller and more energy-efficient pumps in place of the much larger pumps that would be required without the use of an EMUPORT Solids Separation System. This greatly reduces the Life Cycle Costs of the pumping station.

The EMUPORT Solids Separation System is available as a single or dual pump station. With the dual system it offers the benefits of alternating duty pump cycle.

SOURCE: WILO EMU USA