New Nashville Equalization Facility Helps Manage Wastewater Flows

By Thomas Renner

Workers in Nashville recently completed an $18.9 million project to supplement an existing pump station to help manage excessive flows in the existing sewer system.

The Gibson Creek Equalization Facility included the construction of a 10-million-gallon pre-stressed concrete tank and a 22-MGD pump station. The storage tank is utilized when sewer flows exceed the capacity of the Gibson Creek Pump Station. The peak flows are stored until the flows in the system recede, and the stored volume can be conveyed through the system to treatment.

The project was part of upgrades approved by Clean Water Nashville. The Clean Water Nashville Overflow Abatement program, established in 2011, will update infrastructure to decrease sewer overflows, reduce health risks associated with exposure to bacteria and contaminants, and improve water quality in the Cumberland River and Davidson County’s extensive network of streams, creeks, and tributaries. The project was designed in 2016, construction began in August 2021 and completed in February 2024.

“The primary goal of the project is to improve the infrastructure due to a growing population and increase flow,’’ according to Thomas Ward, Assistant Project Manager at Reeves Young, the general contractor for the project.

Project Centerpiece

The new equalization storage tank is the centerpiece to the facility, and those tanks play an important role in wastewater management.

Equalization tanks are designed to buffer flows to a wastewater treatment plant with variants in influent flow due to diurnal variation and wet weather events. Mixing is required in the basins to maintain solids in suspension, preventing deposition, and equalizing load to the treatment plant.

Waste treatment is most effective when conditions are constant. Inconsistent flow rates or batch dumping — which occurs when wastewater is gathered, treated, and then discharged at one time — create changes that affect the biological environment. It also creates the need for constant modification of chemicals.

Equalization minimizes the modifications required for treatment and results in superior operation of the process. It also reduces the amount of capital expenditures for supporting equipment.

Equalization tanks also play an important role in the critical effects of rainwater overflow in wet weather regions and excess sewage. Surprisingly, Nashville receives more rain than Seattle and many other U.S. cities. More than 56 inches of rain a year douse The Music City. Seattle averages around 37 inches per year.

“When the pump station gets overloaded and there is too much wastewater coming through, the system will divert it to equalization tank until it settles down,’’ Ward said. “Then the wastewater will drain back into the regular system. It prevents the storm system from getting backed up. These tanks are fairly common and help the system handle the flow.”

Additional Improvements

The equalization tank served as the primary component to the new facility. There were, however, a wide range of other improvements.

The Reeves Young team improved the existing pump station facility to address settlement and cracking issues and coping repairs. The plan also called for the construction of a new flow diversion structure vault, flow metering vault, equalization pump station, and foundation work including piles, slabs, beams, walls, and miscellaneous concrete work.

Workers also built electrical motor control centers with a standby power generation system and architectural buildings. The project also called for general site work including paving, grading, drainage, fencing and signage, and installation of a sewer pipe and manhole.

“We dealt with flooding several times while we were in construction,’’ Ward said. “In that case, there’s nothing you can do except wait for it to subside. We’d just be dewatering into the Cumberland River and it would flood again. You have to wait until the water settles down, and sometimes that can take about a week. It’s something that we experience quite a bit during some of the wetter months.”

Project At A Glance

What: Workers completed construction of the Gibson Creek Equalization Facility in Nashville. The $18.9 million project included a 10-million gallon pre-stressed concrete tank and a 22-MGD pump station.

Why: The project was part of upgrades approved by Clean Water Nashville to update infrastructure to decrease sewer overflows, reduce health risks associated with exposure to bacteria and contaminants, and improve water quality in the region.

Project timeline: The project was designed in 2016, construction began in August 2021 and was completed in February 2024.

Fighting off corrosion: The project includes 15 access doors manufactured by BILCO. The doors are manufactured with materials that resist corrosion, which occurs frequently in wastewater management facilities.

Did you know? Nashville is one of the top 10 cities in the nation in annual rainfall amount, with an average of more than 56 inches of rain every year.

Corrosion-Resistant Doors

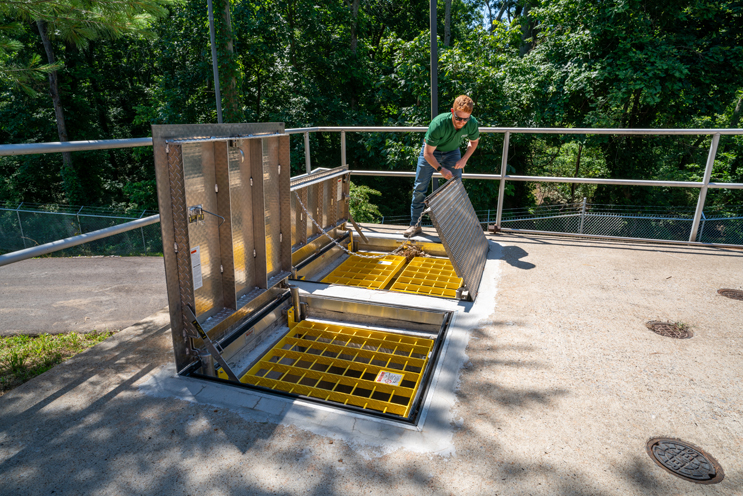

One of the important updates to the new facility was the inclusion of 15 access doors manufactured by The BILCO Company. Various sizes were included in the project, including several H20 doors that are reinforced for AASHTO H-20 wheel loading.

Constant moisture and contaminants create highly corrosive conditions that attack metal and concrete structures, causing deterioration and forcing early repair or expensive replacement. The BILCO doors are manufactured with corrosion resistant materials and provide exceptional durability in a caustic environment.

“You need to have stainless steel when dealing with sewage treatment plants and corrosive materials,’’ Ward said. “They also have gaskets to seal in moisture. From a containment standpoint, that’s the biggest advantage to those doors.”

The doors allow access to valve vaults, a wet well and the diversion structure. Some doors were replaced on existing buildings at the pump station, Ward said.

BILCO doors are engineered with lift assistance for smooth, easy one-hand operation regardless of size, even on the unusually heavy H-20 doors. Some of the H-20 doors weigh more than 1,100 pounds. They also include hold-open arm locks to keep the cover in the open position, heavy duty construction, and a positive latching mechanism to prevent unauthorized access. Compton Sales, BILCO’s representative in Georgia, provided the doors for Reeves Young.

Population Boom

The upgrades authorized by Clean Water Nashville are part of a systemic plan to keep pace with a growing population. Earlier this year, the Nashville Area Chamber of Commerce reported the region increased by more than 31,500 residents in 2023. The Chamber said that figure equals about 86 people per day.

Increasing population, however, also requires critical infrastructure improvements. Clean Water Nashville established an Overflow Abatement Program in 2011 to address sewer capacity issues, improve infrastructure, and reduce health risks associated with exposure to bacteria and contaminants.

“The program to improve the wastewater infrastructure system will provide lasting benefits for future generations, improve water quality, and provide a clean, healthier environment for our citizens,’’ the agency says on its website.

Thomas Renner writes on building, construction, and other trade industry topics for publications throughout the United States.