Need More Water? Think Ozone-BAC For 'One Water' Resolution

By Vijay Sundaram

If you thought reverse osmosis was the one and only choice for potable water reuse, think again. Ozonation followed by biological activated carbon (ozone-BAC) is more suited to inland communities and may be better at removing chemicals of emerging concern (CECs).

A finite freshwater supply and an ever-increasing demand for water are making sustainable water resource management necessary for many cities. Inland and coastal communities alike are becoming more waterconscious and are planning or have already implemented waterconservation measures to reduce their water demand/water footprint.

For most communities, the next step in sustainable water resource management is diversification of their water supply portfolio. Considering the available new water supply options, highly treated municipal wastewater is the most reliable, yet underutilized source of freshwater in many urban areas.

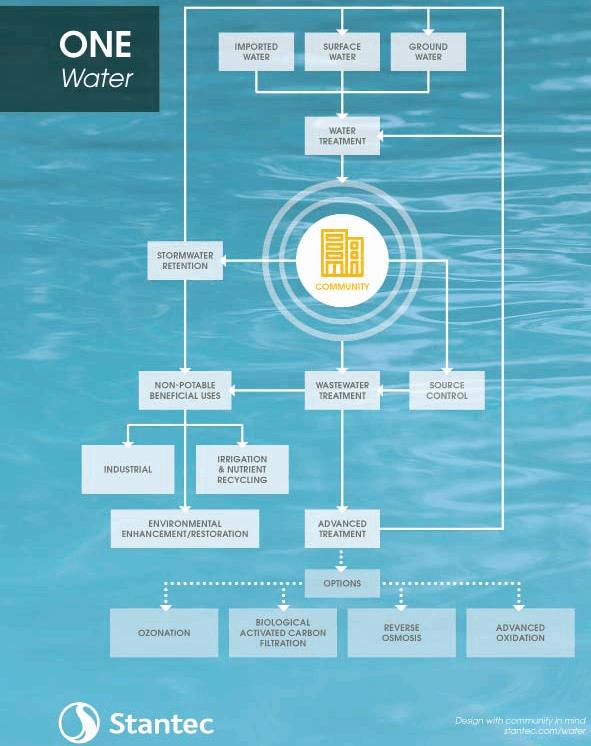

Figure 1. Illustration of One Water approach

Reuse of refreshed municipal effluent is not new. Well-known reuse projects have been in practice since the 1980s. However, the methods for providing advanced treatment to wastewater and the realistic options for reuse water have changed significantly. The new water planning paradigm considers all water in the hydrosphere as “one water,” and the potential for use and reuse is summarized schematically in Figure 1. When considering wastewater as a reliable source for augmenting a community’s water supply, there are two basic options:

Dual Pipe (Conventional): Dual plumb the community (i.e., install “purple pipe”) to keep recycled water separate from potable water.

Single Pipe (The Future): Refresh the wastewater to where it is safe for potable water augmentation.

The “Dual Pipe” approach spends less money on wastewater treatment but more on the dual-pipe distribution system, its long-term maintenance, and control of “cross connections” risk.

The “Single Pipe” approach spends more money on advanced wastewater treatment but less on distribution piping and has no cross-connection concerns. Improvements in advanced wastewater treatment technologies are tilting the economics in favor of the “Single Pipe” approach. Consequently, numerous cities and towns are currently planning and implementing potable reuse projects as the more economical alternative.

In implementing a One Water future, both regulators and the public are concerned about pathogens, carcinogens (such as disinfection byproducts [DBPs], pesticides, heavy metals, etc.), and chemicals of emerging concern (CECs, which include hormones, pharmaceuticals, personal care products, etc.).

Pathogens, DBPs, And CECs

Pathogens are the foremost concern with every reuse project, particularly One Water projects. Because no water can be tested for every possible pathogen, the regulatory community has studied the matter in detail and has developed analytical protocols that protect public health. Specifically, if removing particular indicator pathogens (e.g., Giardia lamblia, Cryptosporidium parvum, enteric viruses, and coliforms) is demonstrated, then the water is judged safe for reuse, even drinkable. The technologies to remove pathogens from drinking water standards exist and are being implemented.

DBPs are commonly detected in potable water supplies, regardless of whether water reuse is involved. Common DBPs include total trihalomethanes (TTHMs), haloacetic acids (HAA5), bromate, and NDMA (N-Nitrosodimethlyamine). Control of DBPs during water treatment and distribution requires a deep understanding of DBP precursors and formation pathways. As examples, total organic carbon (TOC) is a good indicator of the presence of TTHM precursors; TTHMs can be formed during chlorine-based disinfection processes; formation of bromate during ozonation becomes a concern if relatively higher levels of bromide are present in the influent; NDMA is an emerging DBP formed during chloramination and, to a lesser extent, during ozonation. The key to One Water projects, as with conventional projects to a lesser extent, is controlling DBP concentrations to acceptable levels by the design and operation of the treatment methodologies used. Control of DBPs and other carcinogens to meet drinking water standards is now possible and is being demonstrated by several One Water projects.

Within the water resource profession, the presence of CECs is considered the “fingerprint” that the water has been impacted by human activity, even if the water and its source appear pristine. CECs include hormones, pharmaceuticals, and personal care products. Obviously, municipal wastewater, being heavily impacted by human activity, contains relatively high concentrations of a wide range of CECs. CEC removal has been possible but expensive. Recent innovations related to the application of the ozone-BAC (ozonation followed by biologically activated carbon) treatment process train are paving the way for cost-effective CEC control and potable reuse across the nation.

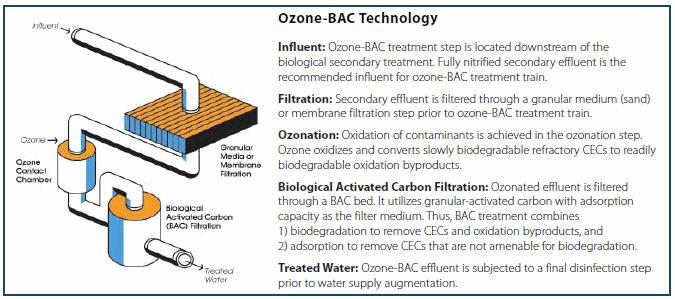

Figure 2. Ozone-BAC technology description

RO — The Gold Standard

Reverse osmosis (RO) is the current “gold standard” for potable reuse of municipal wastewater. RO-based treatment trains have demonstrated removal of pathogens, DBPs, and CECs to drinking water standards. Unfortunately, RO treatment and associated pretreatment steps are expensive to build and operate, and all the removed contaminants are concentrated in a waste stream (sometimes called “reject” or a “brine stream”) that is 10 to 20 percent of the influent flow to the RO process. Disposal of this brine stream is another major expense if oceanic discharge is not available. Therefore, inland locations considering potable reuse are either planning very expensive RO-based treatment trains with brine-handling facilities, or they are exploring alternative treatment trains that are equally effective in providing barriers for pathogens, CECs, and DBPs.

To address the One Water project needs of inland communities, the question was asked whether RO (a desalination process developed decades ago) was truly the best technology for removing CECs, which are primarily organics. The answer to this question may well be no; it’s ozone-BAC technology. The ozonation step oxidizes CECs that are residual from conventional wastewater treatment processes into short-chain organic compounds that are biodegradable. Next, the BAC step metabolizes these shortchain organics into even simpler organics. A schematic of an ozone- BAC process is shown in Figure 2. As shown, treated wastewater must be filtered prior to ozone-BAC treatment. This filter may be part of the wastewater treatment plant or part of the water reuse treatment process. A description of the ozone- BAC process relative to the Figure 2 schematic is presented below.

Ozone-BAC Technology Development And Maturation

While some communities have been utilizing ozone-BAC for decades, engineering services company, Stantec, reported one of the earliest data sets on the CEC removal capabilities of ozone-BAC when treating filtered wastewater. That data set was based on the field performance of an ozone-BAC process operated from 2008 to 2010 at the City of Reno’s Reno-Stead Wastewater Reclamation Facility (WRF). CEC removal in ozone-BAC was extensive and reliable and was achieved mainly via three treatment mechanisms: 1) oxidation, 2) biodegradation, and 3) adsorption, resulting in true treatment, not just concentration.

Filtration tanks for biological activated carbon treatment

Since then, Stantec has been working on the optimization and design of ozone-BAC for potable reuse applications, including water treatment in Gwinnett County. Since reporting the Reno project findings, several full-scale ozone-BAC projects have been implemented in New Mexico and Texas, and field investigations are being conducted in Virginia and Florida. Stantec is currently designing full-scale ozone-BAC processes for agencies in Southern California.

Optimization Of Ozone-BAC For Potable Reuse Applications

Water Environment & Reuse Foundation (WE&RF) Project 15-10 is a research project in collaboration with American Water, Stantec, Washoe County, Nevada, Xylem, and WE&RF. The goals of the project are to:

- Understand water quality differences between ozone-BAC and RO effluents.

- Optimize ozone-BAC treatment mechanisms and design parameters.

- Develop an ozone-BAC guidance manual for potable reuse applications.

The project team is currently conducting diagnostic pilot testing at Washoe County’s South Truckee Meadows WRF in Reno, NV. This research project has been providing valuable insights on the roles of the ozone and BAC steps in controlling DBP formation and maximizing CEC removal. The guidance manual is considered as the next step in ozone-BAC technology maturation as it allows regulators and designers to better understand the technology’s capabilities and limitations.

Ozone-BAC And Its Role In Future Water Management

Ozone-BAC has an important role in removing CECs found in municipal wastewater prior to reuse as part of One Water resource planning. Ozone-BAC-based treatment trains are proven to be effective in providing pathogen log reductions and minimizing DBP formation as well. RO still has a place in One Water planning, but primarily for use in its original role to remove salt if needed, and only to the extent needed based on One Water project-specific factors. In such cases, the RO unit would treat just a portion of the reuse water downstream of the ozone-BAC process.

About The Author

Vijay Sundaram, a chemical engineer by training, has 15 years of experience designing advanced water and wastewater treatment systems using physical, chemical, and biological processes. He is the water resource technology leader at Stantec, and as a resident of drought-sensitive California, he’s focused on creating safe, cost-effective, and reliable water sources.

Vijay Sundaram, a chemical engineer by training, has 15 years of experience designing advanced water and wastewater treatment systems using physical, chemical, and biological processes. He is the water resource technology leader at Stantec, and as a resident of drought-sensitive California, he’s focused on creating safe, cost-effective, and reliable water sources.