Mutag BioChip High-Performance Biofilm Carrier Used In Municipal Wastewater Treatment

In the recent past, a new and very innovative biofilm carrier named Mutag BioChip™, developed and produced by the German company Multi Umwelttechnologie AG, has increasingly and very successfully got into the news with regard to the biological treatment of municipal/domestic sewage. In this field of application, the chip-shaped high-performance biofilm carrier is unsurpassed especially when it comes to nitrification. Attached to the carrier media surface, which accounts for more than 3,000 m²/m³ (914 ft²/ft³) and which is provided in the form of a detailed pore system, the highly sensitive nitrifying bacteria are optimally protected from external mechanical influences. Despite the low diffusion depth of substrate and oxygen, the bacteria are optimally supplied from both sides of the thin carrier (thickness: approx. 1 mm).

In the following, it will be explained by taking the example of the Swiss-based municipal sewage treatment plant (STP) called “oberes Surbtal” how relatively easy it is to significantly enhance the nitrification performance of existing STP’s by applying Mutag BioChip carriers.

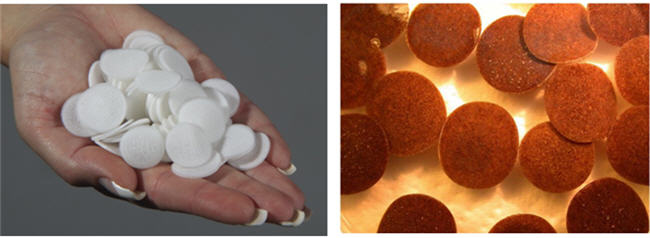

Fig. 1 and 2: Mutag BioChip high-performance carrier media for biofilms – uncolored, w/o biofilm (white) and colored, w/o biofilm (orange).

Before the reconstruction measure, the STP oberes Surbtal had been operated with activated sludge process and was originally designed for treating the sewage corresponding to 16,000 population equivalents (PE). In 2012 and 2013 the reconstruction measure was performed in multiple steps by the Swiss company Techfina SA located in Winterthur whereas the process-technological designing of the new moving bed bioreactor stage (MBBR) was effected in close cooperation with the technology provider Multi Umwelttechnologie AG. After the reconstruction, the STP is now treating the sewage accounting for 20,750 PE and is designed for automatic permanent operation with hybrid process (combination of activated sludge and MBBR process).

The scope of the plant reconstruction was the supply of the complete electro-mechanical equipment for the biological wastewater treatment (hybrid process), of the return sludge pumps as well as the blower station by the company Techfina SA.

The biological treatment stage of the STP consists of three identical trains whereas each train comprises three treatment zones. Within the scope of the reconstruction measure, the respective nitrification zone of each treatment train was equipped with Mutag BioChip high-performance biofilm carriers.

Fig. 3: Sewage treatment plant “oberes Surbtal“. The biological treatment part of the plant consists of three identical treatment trains. Fig. 4: Ammonium-oxidizing (red) and nitrite-oxidizing bacteria (green) in a pore of the Mutag BioChip carrier.

Each single nitrification stage has an active reaction tank volume of 200 m³ and is filled with 27 m³ Mutag BioChip carriers. Hence, the carrier media fill fraction accounts for 13.5 percent of the active reactor volume which is available for the nitrification process.

As mentioned above, the plant had originally been operated with activated sludge process which is characterized by the pollutant-degrading bacteria being present in the form of activated sludge flocs which freely move in the wastewater. After the plant reconstruction, the nitrifying bacteria attached themselves to the Mutag BioChip carrier media. The previous activated sludge reactors are now being operated with hybrid process (also called IFAS; combination of MBBR and activated sludge process) whereas the biofilm carriers are retained by a system of carrier media retention screens installed in the respective nitrification reactor.

Accompanied by the pollutant load which increased according to the upgrade target of the plant, the correspondingly increased oxygen requirement had to be considered. Consequently, the existing blower station was equipped with more powerful blowers.

The aeration systems which had been available in the reaction tanks earlier were completely replaced with high-performance plate-type membrane diffusers.

Within the scope of the upgrading measure of the STP oberes Surbtal, 81 m³ of Mutag BioChip carriers in total were filled into the previous activated sludge tanks at similar percentages and the treatment concept was hence changed from activated sludge process into hybrid process (IFAS). In this connection, the treatment capacity was increased from 16,000 PE to 20,750 PE in terms of the BOD5 load whereas the design of the nitrification part of the plant is based on the ammonium nitrogen load (NH4-N load) of 118 kg to be removed per day. After the finalization of the plant upgrade, all wastewater discharge requirements have been safely and reliably complied with within the scope of the performance test.

Additionally, it must be mentioned that the Mutag BioChip carrier is also in operation in the municipal sewage treatment plant of the city of Erkelenz (Germany) in clear water nitrification since 2010. Another five municipal sewage treatment plants are successfully being operated with Mutag BioChip in Vietnam and Bangladesh since 2012. Moreover, another municipal sewage treatment plant near Leipzig (Germany) having a treatment capacity of 900 PE was equipped with the high-performance biofilm carrier in 2014. At present, further municipal sewage treatment plant projects are about to being implemented and in the future, the Mutag BioChip will show its high efficiency also in these projects.

As outlined above, the treatment capacity of existing wastewater treatment plants is possible to be significantly enhanced simply by adding Mutag BioChip carriers. With regard to this, also containerized wastewater treatment plants, which are complete units from the conceptual point of view, can reach significantly higher treatment efficiency by using the high-performance biofilm carriers.

Fig 5: Containerized wastewater treatment plant operated with Mutag BioChip, installed in Iraq in 2014.

For more information, please visit our website www.mutag-biochip.com and also watch our numerous movies on Youtube (keywords: Mutag, Mutag BioChip).