Leachate — A Key To Unlocking The Chain Of Recirculating PFAS Forever?

By Fabrizio Sabba, Christian Kassar, Patrick McNamara, and Gary Hunter

PFAS contamination is ubiquitous in the water cycle, but landfill wastewater leachate poses an opportunity to treat concentrated streams and break up the continuous movement through the water cycle.

Per- and polyfluoroalkyl substances, better known by their acronym — PFAS — and often called “forever chemicals,” have been gaining increased attention over their presence in the water cycle. Indeed, PFAS are found in all parts of the water cycle, including wastewater, groundwater, surface water, and drinking water. They are ubiquitous because of their widespread use in consumer products such as food packaging, electronics, carpets, shampoo bottles, non-stick pans, and a plethora of other items. Moreover, these PFAS were designed to fight fires and coat our pans while cooking — it should be no surprise that they do not readily biodegrade in the environment. Since a wide variety of everyday products contain PFAS, landfills, and therefore leachate, are a hotspot for PFAS. If PFAS can be treated at landfills prior to leaching into surrounding waterways, the movement of PFAS through the urban water cycle could be limited. So, while leachates are undoubtedly a high, concentrated stream of PFAS, they are also an opportunity for treatment.

Landfill Leachate And PFAS Issues

Leachate is the product of precipitation infiltrating through the solid waste and potentially resulting in a rather complex mixture of dangerous contaminants for human and ecosystem health. Municipal landfill leachate is a source of PFAS contamination due to the extensive discharge of PFAS-rich consumer products. PFAS could take several different routes towards environmental contamination after placed in landfill facilities.

In the U.S., publicly owned treatment works (POTW) are usually responsible for the treatment of this waste leachate, which is commonly co-treated with domestic sewage. While the volume of leachate varies, it can be as much as 1% of the total influent volume at a POTW. The concentrations of PFAS can reach high concentrations in the order of ppm (or mg/L). PFAS treatment can be a challenging problem given the physical and chemical composition of landfill leachate that includes high levels of total organic carbon (TOC), total dissolved solids (TDS), and total suspended solids (TSS), and, in some cases, heavy metals, which may also be at ppm levels. These variables can all impact the downstream technology and the resulting removal and destruction efficiency. Different technologies have been implemented to reduce the discharge of PFAS into the environment.

Technologies To Treat PFAS In Leachate

It is important to state upfront that there are no technologies to date that are able to provide complete PFAS removal in the presence of disrupting species, such as high TOC and TDS, which might cause scaling, fouling, competition, or reduction in treatment efficiency. Conventional biological processes are proven ineffective for PFAS treatment due to their recalcitrance nature. Overall, treatment technologies remove PFAS via either separation/concentration or chemical transformation/destruction.

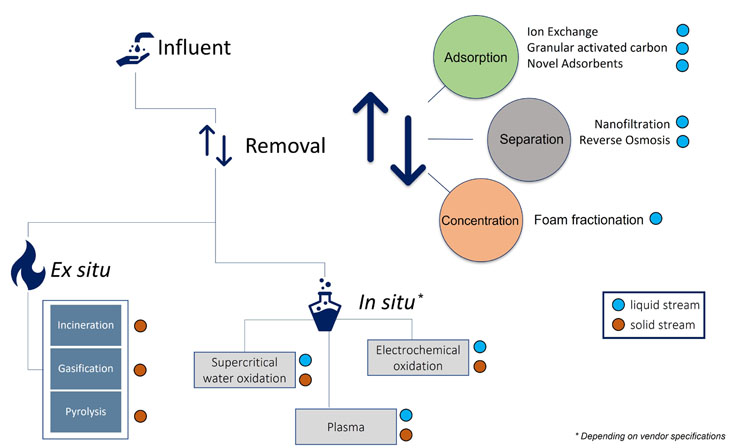

PFAS can be separated and concentrated into different media based on the technology used. For example, membrane separation processes (e.g., reverse osmosis) accumulate PFAS into a concentrated reject stream; liquid-liquid separation processes (e.g., foam fractionation) coalesce PFAS into a sludge-like foamy waste, and adsorption technologies (e.g., activated carbon and resins) precipitate PFAS onto porous materials or recover PFAS in the spent ion-exchange regeneration solution. Chemical transformation/destruction processes are comprised of redox-based and heat-based technologies. Redox-based technologies include supercritical water oxidation, electrochemical oxidation, and plasma. These processes are highly effective at meeting treatment requirements, while at the same time also offering a modular and in situ alternative. Heat-based destruction technologies are characterized by the presence of heating units and can occur in the presence (e.g., incineration and gasification) or absence (e.g., pyrolysis) of oxygen. These processes can volatilize PFAS and contribute to the formation of new, and sometimes unknown, PFAS gaseous byproducts.

As a guiding principle, minimizing the volumes and increasing the PFAS loading rate by concentrating the influent increases the effectiveness of destruction technologies and reduces operational costs. However, these technologies are far from being perfect and have some limitations, as discussed in the next section.

Available technologies to concentrate, separate, remove, and destroy PFAS from waste streams (Credit: Black & Veatch)

Shortcomings Of Current Technologies

Separation/concentration technologies provide cost-effective means for PFAS removal. Among these technologies, foam fractionation shows to be the most promising for landfill leachate applications, since it leverages the common foaming issues of leachate and the surfactant properties of PFAS while minimizing biological waste production due to low pretreatment requirements (for example, TOC removal can be avoided). Given that PFAS remains harmful after shifting to another media (e.g., foam), a destruction step is still necessary. The current common ex situ approaches of dealing with PFAS-laden waste can have sustainability challenges. For instance, incineration would generate high carbon dioxide (CO2) emissions and harmful halogenated species as products of incomplete combustion, while disposal of PFAS waste would only re-contaminate landfills.

Treating and managing PFAS-laden waste has been comprehensively evaluated through life-cycle assessments (LCAs), which showed that combustion technologies, especially incineration, were the greatest contributors to adverse environmental impacts linked to high energy demands and fossil fuel depletion. The leading impact categories pertained to human toxicity cancer, water eutrophication, and ecotoxicity, whereby communities with lower levels of income, education, and infrastructure development were the most impacted. Moreover, a well-trained staff should operate the incinerators and thermal reactors to provide the right temperatures (i.e., >1,000°C), residence times, oxygen supply, and proper maintenance. Failure to secure at least one of the latter conditions would result in the formation of PFAS intermediates due to partial mineralization. A middle-ground solution is needed to address equity and social justice issues associated with exposure to PFAS from untreated waste (i.e., disposal) or harmful emissions (e.g., incineration).

Emerging destruction technologies have proven to be viable in situ alternatives with >99% treatment effectiveness, high modularity, and short reaction times, but have also presented several limitations given the minimal number of scale-up studies, which reflects the low level of readiness for full-scale deployment. Most novel processes require high energy inputs to degrade PFAS — whether by increasing the temperature and pressure of the receiving waters and/or producing radical species. Additionally, the complexity of leachate presumes continuous fouling and replacement of expensive equipment due to salt deposition, electrode passivation, or system degradation from extreme operating conditions (e.g., high temperatures, pressures, hardness, TDS). Other challenges include the formation of toxic byproducts such as trihalomethanes (THMs), haloacetic acids (HAAs), chlorate, and perchlorate through the degradation of untargeted species (e.g., TOC, natural organic matter). Finally, destruction processes have only been proven effective for long-chain PFAS (e.g., perfluorooctane sulfonate (PFOS), perfluorooctanoic acid (PFOA) while shorter-chain counterparts (e.g., perfluorobutane sulfonate (PFBS), PFBA) are understudied. The latter compounds are less surface active and more soluble in water, therefore requiring the addition of chemicals such as coagulants, metal catalysts, polymers, and surfactants to promote degradation.

Ongoing And Evolving Regulatory Changes To PFAS Levels

On October 18, 2021, the U.S. EPA laid out a strategic approach to address PFAS and set a roadmap with specific timelines to deliver advanced policies and take action to protect human health and the environment, and hold polluters accountable for PFAS contamination. Particularly, this comprehensive approach is a commitment to action for the years 2021-2024. The roadmap is based on three goals: research, restrict, and remediate:

- Research represents an important aspect of tackling the “novel and unknown” topic of PFAS as we increase the understanding of the environmental impacts and the adverse health effects associated with long-term exposure to PFAS.

- Restrict becomes a cost-effective key action to minimizing human exposure and ecotoxicity by reducing industrial discharges of PFAS-containing products in the environment. Since PFAS partition between several phases other than water, such as soil and air, tackling PFAS at its source would mitigate its ubiquity.

- Remediate is to clean up what is already out there in the environment. This is a critical step that calls for urgency to minimize ecotoxicity and human health concerns.

As research on this topic advances, the EPA is issuing lower drinking water health advisory limits for legacy PFAS (e.g., PFOA, and PFOS) while concurrently finalizing new advisory limits for other PFAS (e.g., hexafluoropropylene oxide dimer acid, GenX, and PFBS). While waiting for federal guidance, some states have moved forward with PFAS control measures for biosolids as well. More than 30 states have already started taking state-level approaches to control and mitigate PFAS, whether as part of a monitoring strategy or a source reduction plan.

The regulatory pillar to resolving the issue associated with PFAS contamination is crucial but promising. This becomes even more promising on a federal level with the EPA’s most recent and exhaustive PFAS Strategic Roadmap, which will provide a stricter course of action and an alleviated PFAS environment in the coming years.

What Will Research Focus On In The Future?

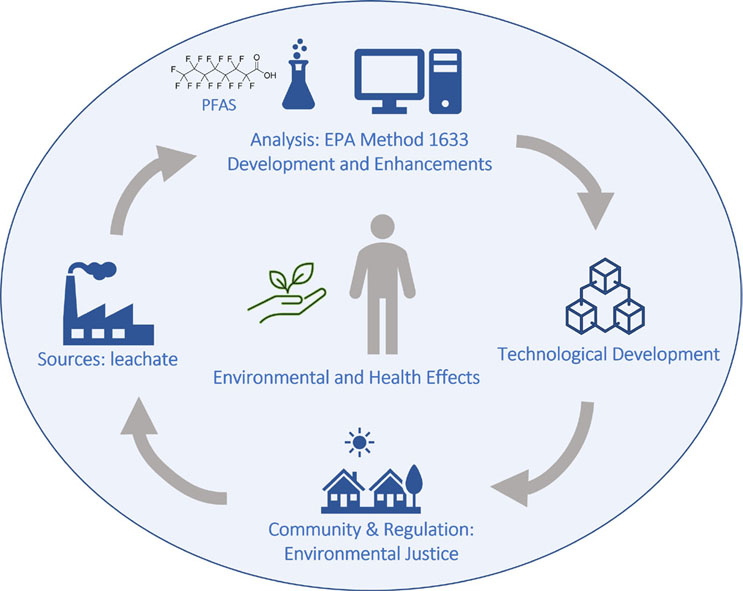

In recent years, the removal and destruction of PFAS has become an active topic of research with substantial progress. However, research is still heavily needed on this matter, and the following points require particular attention:

- The quest for scale-up studies

Despite the effectiveness of innovative PFAS-specific technologies, most studies are still at laboratory-scale level and pertain to specific operating conditions, thus limiting their commercial applicability. There is a need for conducting scale-up studies that compare multiple technologies under uniform conditions to provide a standardized treatment approach for PFAS applications.

- The need for better detection

As of June 2022, the EPA has issued new health advisory limits in drinking water several orders of magnitude lower than the existing detection limits. Given that the federal PFAS exposure regulations are expected to be promulgated soon, an enhancement of PFAS detection methods should be highly pursued to provide cheaper and more accurate detection measures. Noteworthy, Method 1633 is anticipated to be approved soon, and it tests for 40 PFAS in a variety of environments, including wastewater, biosolids, soil, and landfill leachate. Validation and subsequent approval of this method will allow research, monitoring, and potentially even regulations to move forward.

- Highly wanted economical solutions

PFAS are highly resistant to degradation, ubiquitous in the environment, and harmful to humans. Emerging destruction technologies are propitious in terms of treatment efficiency but are not ready for implementation due to lack of scale-up studies and associated capital and operating costs. To better serve deprived communities that do not have the prestige of acquiring high-end technologies, the federal government should continue promoting research investments in municipal facilities to pursue economically viable solutions for managing PFAS in treatment plants.

- Environmental justice concerns over incineration

Incineration, due to its unknown production of PFAS gaseous byproducts, has been the focus of attention for many studies of environmental justice. Particularly, a connection between the location of these incinerators and the characteristics of the communities indicates that individuals with lower incomes and lack of education are at higher risk of exposure, denote a case of environmental justice and health equity. Further research is needed on incineration to advance the knowledge about its safety and to establish exposure prevention practices to ameliorate individual and community protection along with health equity.

The Bottom Line

Several emerging treatment arrangements have been used to address PFAS contamination in landfill leachate using bench-scale tests and showed promising candidacy to substitute conventional processes. Nonetheless, the applicability of emerging technologies is still constrained by the limited availability of bench- and pilottesting results. More research development is needed using the multi-technology validation approach (i.e., side-by-side testing under uniform conditions) before deployment at full-scale and under more challenging conditions. The additional data will help identify the most cost-effective tandem treatment trains, reduce the formation of toxic intermediates, and refine the operating costs by improving the hydraulic capacity and energy requirements. While these emerging technologies may not be ready for use on a practical scale, their prospects and development show rapid progression as new water regulations increase their pressure.

Summary of future key issues related with PFAS in leachate (Credit: Black & Veatch)

In the meantime, as emerging technologies strengthen, a particular and comprehensive strategy is required to reduce the use of PFAS chemical at the source. There will be more pressure as state regulatory agencies ban the use of PFAS in industrial and commercial applications. For example, Michigan and New York are banning PFAS in firefighting foams and Washington State passed bills eliminating PFAS in food packaging, all of which is encouraging other state regulatory agencies such as Rhode Island and New Jersey to consider similar measures.

The adverse health impacts associated with chronic exposure to PFAS are inevitable in deprived communities due to exponential bioaccumulation in environmental matrices. This calls for urgent and immediate measures. Will the regulatory and technological developments transpire in time? Or will the rapid spread of these harmful chemicals be too large to be contained? Whatever the future holds for regulatory environments, as long as PFAS are in consumers’ products, then PFAS will be in leachate. Therefore, leachate will serve as an opportunity to break the chain of PFAS going from consumer products and into the ever-cycling urban water cycle.

About The Authors

Fabrizio Sabba, PhD, is a Process Engineering Associate with Black & Veatch. His interests include biological processes for nutrients removal and resource recovery during water and wastewater treatment, with a focus on process modeling, biofilm modeling, and biofilm treatment technologies. Currently, he is tackling PFAS removal and destruction via evaluation of different technologies at bench-scale and full-scale.

Fabrizio Sabba, PhD, is a Process Engineering Associate with Black & Veatch. His interests include biological processes for nutrients removal and resource recovery during water and wastewater treatment, with a focus on process modeling, biofilm modeling, and biofilm treatment technologies. Currently, he is tackling PFAS removal and destruction via evaluation of different technologies at bench-scale and full-scale.

Christian Kassar is currently working in the Process and Design Water Engineering industry at Black & Veatch. Christian’s work interests include surface and subsurface water treatment processes for target chemical contaminants, with a narrower emphasis on emerging substances such as PFAS.

Christian Kassar is currently working in the Process and Design Water Engineering industry at Black & Veatch. Christian’s work interests include surface and subsurface water treatment processes for target chemical contaminants, with a narrower emphasis on emerging substances such as PFAS.

Patrick McNamara, PhD, PE, is a wastewater process engineer with Black and Veatch and an associate professor with Marquette University. He researched the impacts of PFAS on anaerobic digestion for his PhD, and has been leading research on pyrolysis of biosolids for the last 10 years. He was recently awarded a Water Research Foundation project with his Black & Veatch team to study the impacts of thermal treatments on the fate of PFAS in solid, liquid, and gas streams.

Patrick McNamara, PhD, PE, is a wastewater process engineer with Black and Veatch and an associate professor with Marquette University. He researched the impacts of PFAS on anaerobic digestion for his PhD, and has been leading research on pyrolysis of biosolids for the last 10 years. He was recently awarded a Water Research Foundation project with his Black & Veatch team to study the impacts of thermal treatments on the fate of PFAS in solid, liquid, and gas streams.

Gary Hunter is a Wastewater Treatment Technology Practice Lead at Black & Veatch. He is responsible for process evaluation for both domestic and industrial wastewater treatment facilities. In this role, he is responsible for industrial pretreatment programs, screening, grit, filtration, and disinfection process trains of the treatment plant. In this work, he has gained expertise in the design, operation, and troubleshooting of wastewater treatment processes. He serves as a UV process consultant to EPRI, conducting studies and training for water and wastewater facilities across the U.S.

Gary Hunter is a Wastewater Treatment Technology Practice Lead at Black & Veatch. He is responsible for process evaluation for both domestic and industrial wastewater treatment facilities. In this role, he is responsible for industrial pretreatment programs, screening, grit, filtration, and disinfection process trains of the treatment plant. In this work, he has gained expertise in the design, operation, and troubleshooting of wastewater treatment processes. He serves as a UV process consultant to EPRI, conducting studies and training for water and wastewater facilities across the U.S.