JWC Environmental Introduces Finescreen With UHMW Panels

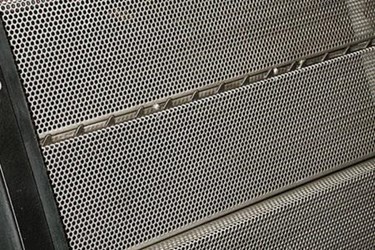

Costa Mesa, CA — For decades JWC's Finescreen Monster® has utilized stainless steel, perforated plates bolted directly to the drive-chains. Now, for the first time, JWC has created a unique ultra high molecular weight (UHMW) polyethylene perforated panel — similar to the panels used on the high capture efficiency Bandscreen Monster® for many years.

A significant benefit of this design is the use of JWC's Staple Guard technology to reduce the chance of debris "stapling" (or hair-pinning) on the highly abrasion/wear/corrosion resistant panels. With less debris sticking to the panels, the design reduces the use of panel cleaning brushes and maximizes the efficiency of the existing spray-wash system.

Each UHMW panel slides into the stainless steel frame allowing for easy removal and maintenance. While similar in design to the existing stainless steel panels, UHMW panels can be removed from the frame without removing the entire panel assembly from the screen.

One benefit of easy to remove panels is the ability to change the entire screen from one perforation size to another as flow or design parameters change. For example a screen with 6mm perforations can easily be changed to one with 3mm perforations.

According to the 2005 United Kingdom WIR report, perforated plate screens have a screenings capture ratio double that of bar screens- ensuring more of the trash is removed at the headworks.

SOURCE: JWC Environmental