Improving The Resilience Of A UV System For Wastewater Disinfection

By Gabriela Ber and Ludwig Dinkloh

Climate change is increasing severe weather patterns and it is a global phenomenon. For the United States, the U.S. EPA has summarized climate change indicators from 1910 to 2020 including heavy precipitation, showing an increase in heavy precipitation over time frames ranging from single days to seasons to years. One important consequence for wastewater treatment plants (WWTPs) is that they now need to cope with sudden increases in the effluent volume with the receiving waterbodies equally carrying more water and being in flood conditions. This is especially true for the final treatment step — disinfection prior to discharge.

Background And Challenge

The Lebanon WWTP in Southeast Pennsylvania discharges into the Quittapahilla Creek. The plant requires that effluent be disinfected 365 days a year. The main disinfection step has been an ultraviolet (UV) since 1996. With increased flooding events from the adjacent creek the existing UV system became inoperable during flooding. The WWTP turned to Veolia Water Technologies & Solutions (Veolia) to help resolve their challenge of additional water volumes and flooding.

The customer needed a system that could consistently disinfect with UV and a flow rate designed for peak flow of 8 MGD (~1,250 m³/h), with a peak instantaneous flow of 30 MGD (~4,700 m³/h). The typical influent quality into the UV system is:

- UV transmittance (UVT) 65%

- Total suspended solids (TSS) < 5 mg/L

- Influent fecal coliform (FC) counts. 2 x 105 colony-forming units (CFU)/100 ml

After analyzing the situation, Veolia proposed an immersed UV system, the Aquaray* 3X, to handle the variable treatment flows and potential flooding conditions. In order to adopt this updated technology, the Lebanon WWTP needed to validate the UV system.

Because the new submersible UV system had the identical in-channel mechanical design for both the submersible and non-submersible systems, the customer was able to use an identical validation equation. This reduced cost for the customer as civil structures did not need to be adapted.

Why UV Validation Testing Is Needed

Establishing a uniform protocol for the performance testing of UV systems first took place for the application of drinking water disinfection in central Europe. Similar protocols were created either specifically for wastewater disinfection (including reuse) or irrespective of application: Ultraviolet Disinfection Guidelines for Drinking Water and Water Reuse by NWRI, Ultraviolet Disinfection Guidance Manual by the U.S. EPA, and Uniform Protocol for Wastewater UV Validation Applications by the IUVA.

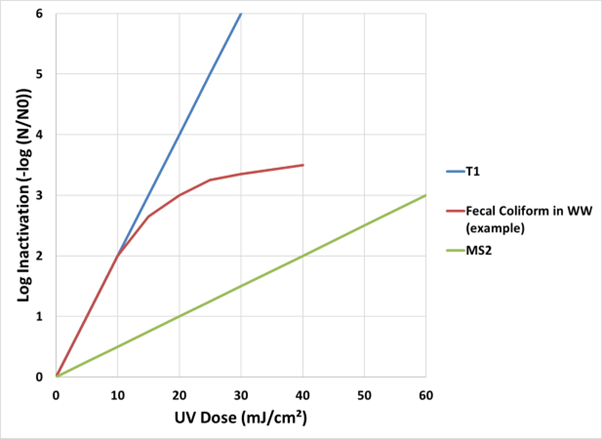

The actual disinfection requirements for wastewater discharge and/or reuse are diverse and include limits for different organisms (e.g., coliforms, enterococci, protozoa, virus). Due to their difference in UV sensitivity, it has become common practice to validate the performance of a UV system with two different indicator organisms, one with a high UV sensitivity and the other with a lower UV sensitivity:

Figure 1. Log inactivation of 3 organisms during validation/testing

With this approach, the resulting validation equation (performance prediction) brackets any organism with a UV sensitivity within the two tested ones. As per Figure 1, T1 is an excellent surrogate for bacterial indicator organism inactivation since they have a similar sensitivity to UV light. Equally important is that any specified UV dose value needs then to be coupled with the UV sensitivity of the relevant organism in order to avoid misleading statements.

Veolia’s Aquaray 3X was designed with a validated UV dose of 31.5 mJ/cm² (for MS2) at peak flow, delivering a 3-log reduction (99.9%) as fecal coliform and ensuring consistent effluent fecal coliform counts of less than 200 CFU/100 ml in the summer, and less than 2,000 CFU/100 ml in the winter. Additionally, the UV disinfection system meets the National Pollutant Discharge Elimination System (NPDES) permit for the effluent limits assigned to the Lebanon WWTP having instantaneous maximums for fecal coliform as a geometric mean of 1,000 and 10,000 CFU/100 ml for the summer and winter, respectively.

Figure 2. Aerial view of Lebanon WWTP

Solution

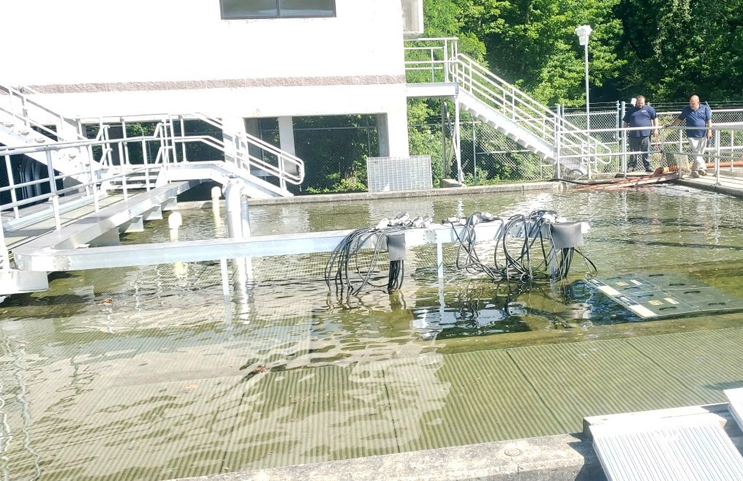

The submersible-design Aquaray 3X-S was installed at Lebanon in June 2021. For this upgrade, the civil structure was left unchanged as the two channels provided adequate room to install new UV modules downstream of the existing ones.

With the new Aquaray 3X-submersible modules installed, the plant now operates the UV system during high rain and water level events and the UV system does not require removal of the UV modules from the channel in preparation of plant flooding events. All fecal coliform counts in the effluent were ≤10 CFU/100 ml which corresponds to a maximum 4-log reduction (99.99%) through the UV system.

Figure 3. UV system in operation under normal conditions

Figure 4. UV system under flood conditions during testing

Conclusion

Increasing the resilience of critical infrastructure and process equipment is a critical task for wastewater utilities around the world.

UV disinfection systems are typically the last step prior to discharge and hence potentially in a more frequent flood zone within the WWTP.

Submersible designs which are equally validated and can therefore be applied for the same design requirements are available as retrofits to eliminate damage to the process equipment and hence minimize off-time and/or discharge violations.

Because the retrofit project at the Lebanon WWTP was successful, other, larger WWTP UV systems used this immersible UV technology to achieve the resiliency realized in Lebanon.

Gabriela Ber has been Product Manager for Purification & Disinfection at Veolia Water Technologies & Solutions since April 2023. She mainly supports the development of the Aquaray UV product line, bringing with her eight years of experience in product management and development in the energy industry.

Gabriela Ber has been Product Manager for Purification & Disinfection at Veolia Water Technologies & Solutions since April 2023. She mainly supports the development of the Aquaray UV product line, bringing with her eight years of experience in product management and development in the energy industry.

Ludwig Dinkloh, Global Sales and Commercial Strategy Leader - Purification & Disinfection, has been Global Sales Leader at Veolia Water Technologies & Solutions since July 2020, being responsible worldwide for the sales of Ozonia* ozone systems and Aquaray UV systems. He has a cumulative 30 years of experience in the water treatment industry.

Ludwig Dinkloh, Global Sales and Commercial Strategy Leader - Purification & Disinfection, has been Global Sales Leader at Veolia Water Technologies & Solutions since July 2020, being responsible worldwide for the sales of Ozonia* ozone systems and Aquaray UV systems. He has a cumulative 30 years of experience in the water treatment industry.

*Trademark of Veolia; may be registered in one or more countries.