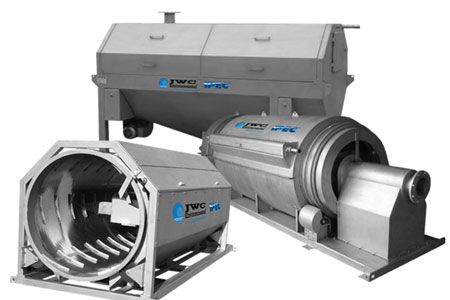

IFO, IFS & IFU Internally Fed Drum Screens

Industrial Screens To Achieve Superb Solids Separation

JWC’s line of Internally Fed Rotary Drum Screens (IFO/IFU/IFS) for industrial applications are designed to provide superior solids recover from wastewater streams. JWC has been providing reliable and robust screening solutions globally through its IPEC brand since 1979. They have been used in a variety of food & beverage and industrial wastewater applications including beef, hog, poultry, and seafood offal, protein rendering, fruit and vegetable processing, pulp & paper production just to name a few.

JWC offers its IFO, IFU and IFS Internally Fed Drum Screen products as a family of solutions to meet the variety of unique industrial applications. All of the product are constructed with 304 stainless steel with the cylindrical drums rolling UHMW polyethylene trunnion wheels with sealed bearings. Influent into the screens enters through a specially designed headbox that efficiently distributes to flow onto the drum to maximize throughput and minimize the required size of the screen. The drums rotate at 4-5 rpm allowing liquid to flow out while internal flights drive solids out the end of the drum. All units include a fixed external spray bar that operates only as needed to minimize water usage.

All units are customized to meet the specific needs of the application. Options can include 316 stainless steel, internal spray bars, customized controls, and variable frequency drives. The screening drum medias, which include wedgewire, perforated plate, and wire mesh is selected to optimize the processing performance of the application.

The IFO screen is supported on a 4” tubular frame, has a top-mounted TEFC motor and is typically applied to flume waters.

The IFU is a compact uni-frame screen that typically is applied to effluents containing moderate to low solid loadings.

The IFS is a base frame mounted screen that is versatile and can handle high flows and/or high solids.

Benefits

- Head box design optimizes throughput to minimize size of required screen

- Intermittent spray wash reduces water usage

- Screening media optimized for various applications

- Collect solids for sale or disposal

- Proven design offers time-tested, consistent results

- Robust design and all stainless steel construction reduces down-time and maintenance costs

- Easy access to all maintenance items

- Higher capture rate compared to conventional moving media screens

Specifications

- Drum Diameters range from 18 to 80 inches

- Drum Lengths range from 24 to 180 inches