World Water Works MBBR™ / IFAS™

The Moving Bed Biofilm Reactor (MBBR) process is a state-of-the-art fixed-film (or attached growth) biological process used for wastewater treatment both municipally and industrially for BOD removal, nitrification and denitrification. This process provides the smallest footprint biological system, which is tolerant of both load swings and temporary load deprivation.

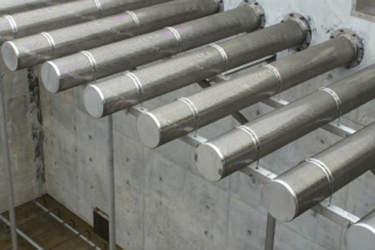

The Ideal MBBR™ consists of a tank with submerged, but freely moving, specially designed bio-media. The large surface area of the bio-media provides abundant surface for bacteria to grow and thrive. A stainless steel aeration manifold installed in the bottom of the aerobic reactors provides both dissolved oxygen for BOD removal / nitrification and mixing by means of a blower. A stainless steel sieve near the top of the tank allows the water to exit the reactor while retaining the bio-media in the tank. The bacteria will digest the organics in the waste stream and convert the soluble material to biomass, which can be removed downstream. A World Water Works’ Ideal DAF™ is placed downstream of the MBBR tank to separate the biomass and the solids from the wastewater.

For denitrification, anoxic MBBR tanks are used. The anoxic tank is similar to aerobic MBBR tanks except that no oxygen is supplied. The tank contains no diffusers and the media is kept in suspension in the reactor through submersible mixers. Other features are the same as in the aerobic reactor although the design may be slightly different.

World Water Works specializes in the combination of the MBBR technology with Integrated Fixed Film Activated Sludge (IFAS) technology or Dissolved Air Flotation (DAF) technology for advanced wastewater treatment.

ADVANTAGES

- Simple to operate

- Easily retrofitted with a small footprint

- Low capital cost

- Stable under load variations

- Increases plant capacity and allows upgrades to new nitrogen limits using existing tanks

- Industrial pre-treatment to lower loads to POTW

- Generates low solids and requires no sludge recycling

- Shaves off 60-80% influent BOD for easy industrial upgrades to existing systems

- Reduces the load to downstream activated sludge process

- Dissolved oxygen meter allows control of the amount of dissolved oxygen injected into the waste stream

IDEAL IFAS™

The upgrading of conventional activated sludge systems to meet new effluent ammonia or total nitrogen limits is done by incorporating specialized bio-media into portions of the existing aerobic zones to cultivate the slower growing AOB/NOB bacteria to aid in the reduction of ammonia. The MLSS will degrade the nitrate in pre-denitrification (MLE configurations) while the MLSS in aerobic reactors will provide for BOD removal and possible partial nitrification. The use of our Ideal IFAS™ system is a cost-effective upgrade for wastewater treatment plants needing to meet new more stringent effluent limits.

ADVANTAGES

- High loading rates

- Small footprint and low capital cost

- Requires minimal new tankage for IFAS upgrade

- Reliability

- Ease of operation

- Compact design

- Designed for future loading

- Stable under load variations