How To Minimize Downtime In Ultrapure Water Systems

Ultrapure water (UPW) systems are vital for industries such as semiconductors, pharmaceuticals, power plants, and secondary battery production. However, climate change poses significant risks to their stable operation, with extreme weather and rising sea levels affecting water quality and supply. These challenges demand innovative solutions to ensure efficiency, reliability, and sustainability in UPW production.

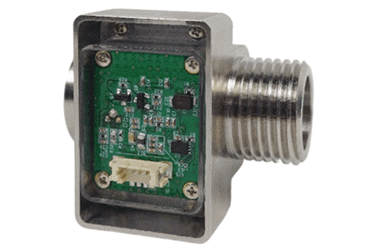

This article will explore a cutting-edge sensor technology that addresses these challenges by revolutionizing key processes in UPW systems. Real-time integrity testing in Reverse Osmosis (RO) systems enhances predictive maintenance, prolongs equipment life, and minimizes costs. In Ultrafiltration (UF), real-time turbidity sensors optimize backwashing intervals, reducing downtime, water, and energy consumption. Meanwhile, the integration of bacteria quantification sensors in Total Organic Carbon (TOC) processes allows near-instant detection of bacterial contamination, dramatically reducing response times compared to traditional methods.

These advancements ensure operational stability, cost-effectiveness, and resource efficiency, setting new benchmarks for UPW management. By leveraging real-time monitoring and predictive analytics, these solutions not only mitigate the impacts of climate change but also empower industries to achieve sustainable growth. As ultrapure water becomes increasingly indispensable, these technologies redefine industrial standards, fostering resilience and competitiveness in a rapidly evolving global market.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.