How To Install pH Sensors

By Frederick J. Kohlmann, Endress+Hauser

This article is for those of you who need to install a new or redo an existing pH loop. These tips can help ensure accurate and consistent readings.

First of all, handle pH sensors carefully. A pH sensor is a delicate instrument and should be handled accordingly. As most pH sensors are made of glass, or plastic bodies with glass measuring ends, care must be taken so the glass is not broken by mishandling or abuse.

For new installations, make sure the sensor is accessible, and easy to remove and re-install for cleaning and calibration (Figure 1). If outdoors, consider how winter freezing or summer heating will impact the sensor. Locate the sensor away from rain or snow if possible.

Figure 1: An example of a pH sensor installation in a convenient location for maintenance by plant personnel.

Sensors have to be removed periodically for calibration, cleaning or replacement—so don’t install a pH sensor in a tank without insertion and retraction hardware. It’s more expensive than just threading a sensor through a nipple, but less expensive than having to drain the tank to remove the sensor.

If installed in a tank, mount the sensor away from the reagent addition so proper mixing can occur. If installed in-line, verify proper mixing has occurred between the process and reagent, through use of an inline mixer if required.

Redundant installation of pH sensors is often required to ensure accurate measurement. Where possible, triple redundancy is the best bet, and the three readings should be sent to an automation system enabled with a 2-out-of-3 voting control scheme. If one sensor consistently disagrees with the other two, it probably needs to be cleaned and calibrated.

Finally, make sure the desired pH measurement is feasible. pH sensors are manufactured for specific uses. Different models are made to withstand high/low temperatures and/or pressures, and the effects of different types of media that tend to coat, plug or otherwise contaminate the reference electrode. It’s important to work with the manufacturer to select the pH sensor best suited for your application.

Process Conditions

For most applications, the flow velocity across the pH sensor should not exceed 10 feet per second. At elevated flow rates, metal salts leach from the glass surrounding the sensor, turning its membrane into ordinary high impedance glass.

Excess pressure and/or temperature can negatively affect sensor life, particularly if process temperatures rise above 80C for prolonged periods. Newer types of glass and flowing references help, but this rule of thumb is a good one.

pH sensors and transmitters are often equipped with temperature compensation routines. These software tools are designed to compensate for the effect of temperature on the sensor glass. Each process behaves differently, and the effects of temperature on the pH measurement should be examined independently for each solution.

Keep it Clean

It’s important to remove pH sensors for cleaning on a regular basis. pH sensors get exposed to materials that can coat or foul the device. pH sensors should be cleaned regularly with soap and water. A weak acid can be used (4-5% W/V HCl) to remove scale from the measuring glass.

Knife blades or wire brushes shouldn’t be used to clean deposits left on the glass bulb as they can scratch the glass or break off the bulb at the neck. A soft bristle brush should be used instead.

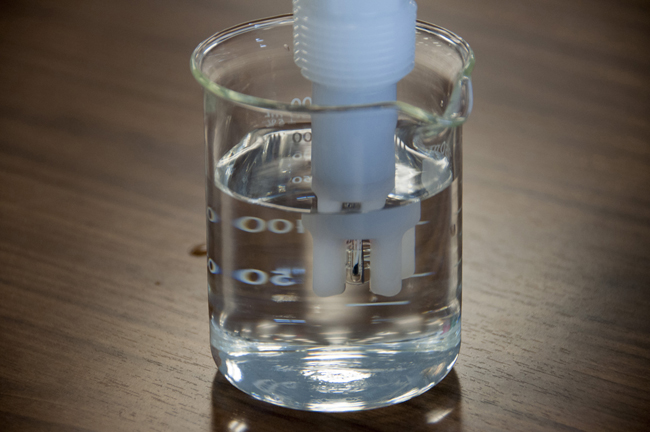

After cleaning, the sensor should sit in a bath of 50% 3.0 molar KCl / 50% 4-buffer for one hour to recondition the sensor and bring the junction potential back to a neutral state. pH sensors should remain wet at all times (Figure 2). Individual plastic boots for the sensor tips can be used, or one large tub for communal soaking. The sensor must also remain wet while installed in process lines and tanks.

Figure 2: pH sensor being kept wet in tap water.

How long will a pH sensor last? A pH sensor in a drinking water plant measuring should last a year or more. We’ve seen pH sensors last for more than six years. We’ve also seen applications where the sensors last just a few days. Sensor life depends on pressure, temperature and flow—as well as the pH and chemistry of the process.

About the author:

Fred Kohlmann is the U.S. Midwest Business Manager for Analytical Products with Endress+Hauser. Since 1976, he has been involved in engineering, design service, marketing, and sales of online analytical water quality and process control instrumentation.