How To Generate (More) Renewable Energy From Water Pipelines

By Ben Wright

A major breakthrough with micro-hydropower turbines allows water distribution networks to generate twice as much renewable energy as previously possible.

A series of pilot projects has been running across the West Coast for the past few years to test and hone next- generation turbine systems which use micro-hydropower to generate renewable energy from the pressure in water pipelines. With those pilots proving overwhelmingly successful, projects have been commissioned across the U.S. and Canada, with further plans (and requests) to install systems from Jamaica to Australia. These new systems will vary from currently installed micro-hydropower pipeline projects in a key way: They will incorporate variable speed drives (VSDs) that double energy-generating capacity.

“The water industry uses as much power as the aviation industry. If we are to fight climate disruption effectively, we need carbon-neutral utilities,” said Gregg Semler, CEO of InPipe, the company behind the pilot projects and technology described above.

|

|

|

|

How And Why It Works

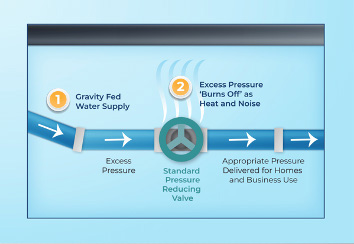

Moving water is energy-intensive. Water utilities and industrial facilities spend an average of 40% of their budget on power — and this cost is rising rapidly alongside the price of energy. At the same time, large water users are constantly managing and regulating water pressure in their systems. Within water distribution systems, water is conveyed across vast networks of pipelines, navigating diverse elevations while maintaining a crucial balance between a minimum operational pressure and avoiding excessively high pressure. To regulate conditions effectively, distribution systems must incorporate pressure-reducing valves that “burn off” excess pressure — turning it into heat, noise, and system wear.

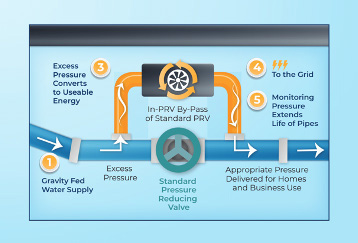

Such valves result in a substantial energy wastage — but this is also an untapped resource. InPipe’s HydroXS systems replicate the functionality of a control valve, but instead of “burning off” pressure, they use micro-hydropower to turn it into a consistent and reliable source of renewable energy.

“Millions of miles of pipelines carrying enormous amounts of potential energy lie beneath our streets and can be tapped to generate predictable, reliable, carbon-free electricity,” said Semler. “We see a future where water pipelines across the world can be tapped to ensure we have power when the electric grid goes down due to extreme weather events."

These systems work on rudimentary hydropower principles — an impeller’s blades rotate as water flows through a turbine at pressure. This mechanical energy is turned into electrical energy by a generator-like component, with the resulting power used either for local utility functions or returned to the grid.

A number of utilities across the West Coast are now incorporating the technology, such as the installation in Hillsboro, Oregon, which produces over 200,000 kWh of electricity annually, translating to roughly one million dollars of electricity over its projected 30-year life span. In addition to power generation, InPipe’s systems offer a suite of analytic tools, enabling operators to manage networks according to actionable data in real time. However, earlier systems used single-speed turbines that, while cost effective, remained limited in the range of flow conditions they could efficiently operate under, resulting in lower energy output and challenging economics for smaller systems.

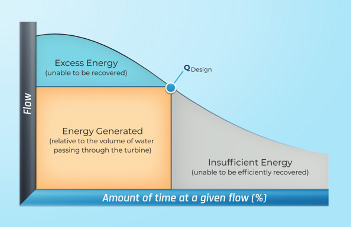

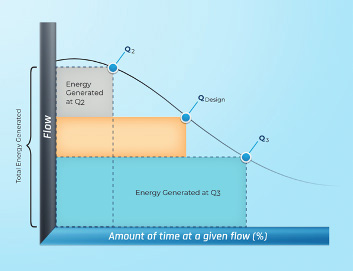

This is because single-speed turbines have a specific efficiency window (design point), regardless of variations in flow or pressure. This creates challenges when operating in variable flows where the hydraulic conditions are not conducive to the design point, and the turbine is not able to optimally or efficiently convert the pressurized water’s potential energy into electric energy. By contrast, the new variable drives modulate the frequency of the generator, ramping the impeller speed up or down to accommodate varying flow and pressure conditions. The pressure control loop aids the process by informing the variable drive how fast or slow to modulate the impeller speed.

“The variable speed drives are innovative and complex — but a simple way to think about it is to compare the difference between riding up and down a hill on a single-speed beach bike to doing so with a multi-speed mountain bike,” explained Semler. “With the single-speed bike, you work hard to get up the hill and coast on the way down. On a mountain bike, you shift the gears up and down to match the ups and downs and maximize your effort. You get up and down the hill with both bikes, but with the mountain bike you have enough left in the tank to climb another!”

An Innovation Imperative

Hydropower is nothing new to the water industry but, until recently, harvesting energy from pipe networks hasn’t been financially or technologically feasible. Placing turbines directly into pipelines has run the risk of disrupting water flow across seasons and conditions. In addition, fossil fuels have historically been plentiful, grids reliable, and federal incentives meager. From a technical perspective, these new systems have gained traction in recent years due to their placement around existing control valves. However, the confluence of grid inconsistency, new federal decarbonization incentives, and heightened urgency around climate change have also played roles in shifting the value proposition. Variable-speed drives look set to push the technology over the threshold.

InPipe is seeing this momentum with a new HydroXS system installation for the East Bay Municipal Utility District (set to generate 130,000 kWh of green energy per year), a distribution partnership on the East Coast with industry veterans GA Fleet, customer engagement to maximize Inflation Reduction Act incentives, and project interest from utilities in locations as diverse as Canada, Jamaica, India, and Australia.

“We exist in such a vital and exciting industry,” noted Semler. “I’m grateful for utilities like Hillsboro and East Bay for their forward-thinking commitment to decarbonization. If we are going to fight climate disruption and empower climate resiliency, we need to decarbonize the water industry. We believe micro-hydropower is a powerful tool in the fight, and it’s up to us to make it available and affordable for many.”

About The Author

About The Author

Ben Wright is a speechwriter, content creator, and media strategist who works across the water/wastewater, higher education, and legislative sectors.