How Acoustic Water Leak Detection Is Used To Tackle Water Loss

By Oded Fruchtman

Italy’s biggest multi-utility, A2A S.p.A., like many water utilities in North America and around the world, had to corral water loss to sustain efficient operations. A2A piloted acoustic leak detection as a potential solution, achieving A+ results.

Water loss is one of the major challenges for water utilities, especially as the global shortage of this critical resource increases. One of the main reasons for water loss is due to the creation of leaks in unseen pipes, which usually develop and expand over a long period of time. Water pipe deterioration leads to a constant increase in operational costs for leak repair, pipe replacement, water waste, and energy waste. Catastrophic bursts are much more expensive to repair than scheduled repairs of background leaks that are detected before surfacing.

Proactive detection and repair of background leaks have huge operational benefits as enormous amounts of water and energy are saved. Furthermore, identifying 1 to 2 percent of critical pipe sections that cause over 80 percent of bursts and replacing them can be cost-effective in the long run.

Acoustic Leak Detection

One of the most successful methods for detecting and locating water leaks that frequently develop in the depths of buried piping is acoustics. In this method, acoustic sensors are permanently installed on the water distribution network and automatically record samples of noises obtained from the water flow in the pipes. In case there are any disturbances such as holes in the piping — i.e., leaks — various noises will be received to indicate this. Different types of pipes and leaks will produce different noises (small vs. large leak, small vs. large diameters, pressure levels, iron vs. plastic pipes, asbestos cement, etc.). Combining acoustic correlation sensors with appropriate analysis algorithms will achieve reliable results that distinguish between different noises and findings. The sensors must be highly sensitive on the one hand — so that they can pick up abnormal noises in the piping — and on the other hand, they must be able to filter background noises outside the pipeline (such as irrigation systems, truck traffic, and more).

An Israeli innovative company, Aquarius Spectrum, developed acoustic solutions that enable water utilities to perform proactive monitoring of their underground assets and hence detect background leaks in their initial stages of development and fix them before they surface and cause serious damage. These solutions, based on sensitive correlating fixed and mobile sensors, can be applied in all types of pipes.

Each night, the sensors record the noise on the pipes and send this information to a cloud-based server. The signals are processed, correlation algorithms are executed, and alerts are issued to the utility regarding leaks or malfunctioning appurtenances, such as hydrants and valves. Analyzed findings are displayed via a user-friendly browser-based display. To date, the company’s technology is monitoring thousands of miles of municipal water pipelines worldwide, helping water utilities reduce their non-revenue water (NRW) and their operations and maintenance (O&M) costs.

How A2A Tackles Its Water Leaks

Founded in 2008, A2A S.p.A. is considered the biggest multi-utility in Italy, with more than 12,000 employees and €6.5B in annual revenue. It generates, distributes, and markets renewable energy, electricity, gas, integrated water supply, and waste management services. From its headquarters in Brescia, Italy, A2A Ciclo Idrico (a company of the A2A Group) operates more than 3,000 kilometers (1,864 miles) of iron water pipes, serving citizens in the municipalities of Brescia and neighboring towns (https://www.a2a.eu/en).

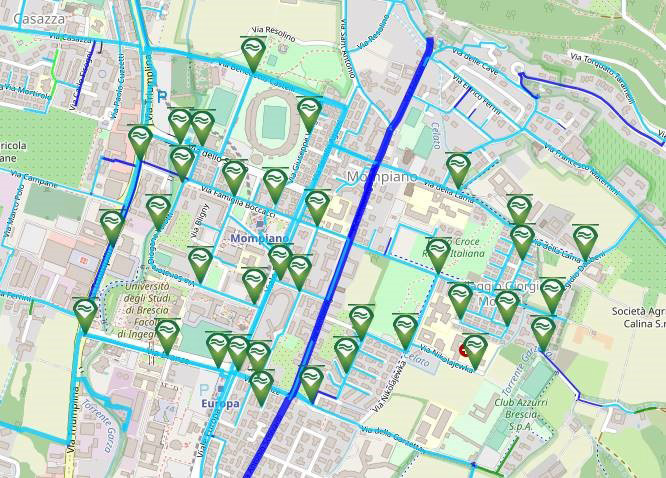

As part of A2A’s intensive efforts to increase their efficiency, they have looked for advanced technologies that will enable them to reduce their water loss and energy costs. During September 2019, the company initiated a leak-detection pilot with Aquarius, carried out in Brescia City. Based on A2A’s GIS data, 39 acoustic correlating sensors have been installed to cover around 15 km (~9 miles) of pipes (See Figure 1).

Figure 1. Sensor installation planning

It should be noted that the pilot site is close to Brescia’s football stadium and despite heavy traffic disruptions due to an important match, within two days all 39 sensors were installed and activated (See Figure 2).

Figure 2. AQS underground acoustic sensor installation

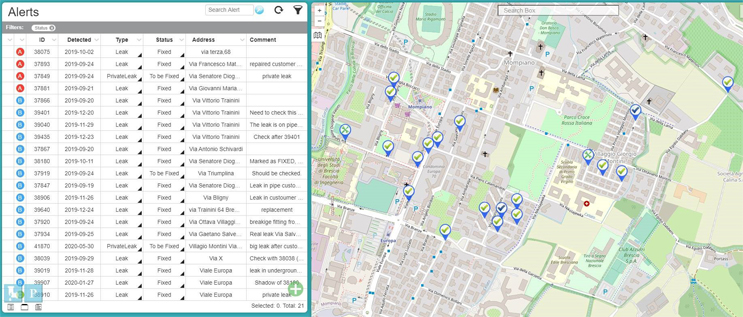

During the first week, 10 hidden leaks were found. One of them was a huge leak that had saturated the ground within a few hours from its time of detection. The final step of the pilot was verifying and pinpointing points of interest (POI) raised by the AQS-SYS fixed monitoring system supported by smartphone-based mobile leak detection equipment. In total, 20 leaks were verified and fixed in just a few months (See Figure 3).

Figure 3. Acoustic map of suspected leaks on the AQS-SYS UI

Thanks to the successful pilot, the Italian utility has recently purchased 235 AQS acoustic sensors that will allow it to continue monitoring the current area and to expand to additional areas. The project continues to be accompanied by the support of Aquarius’ technical team.

About The Author

Oded Fruchtman, EVP of business development at Aquarius Spectrum, has vast experience in managing technology companies and promoting them around the world. He holds a BA in Computer Science and an MBA from the Hebrew University.

Oded Fruchtman, EVP of business development at Aquarius Spectrum, has vast experience in managing technology companies and promoting them around the world. He holds a BA in Computer Science and an MBA from the Hebrew University.