Hexavalent Chromium: Preparing For Version 2.0

By Lee H. Odell And Bill Ketchum

When the California hexavalent chromium maximum contaminant level (MCL) comes back in 2019, treatment technology improvements will have already significantly lowered the cost of compliance.

On Sept. 11, 2017, after the Sacramento County Superior Court found that the California Department of Public Health failed to properly consider the economic feasibility of complying, the state of California rescinded the maximum contaminant level (MCL) of 10 micrograms per liter (ug/L) for hexavalent chromium.1

However, the court also ordered the state to adopt a new MCL for hexavalent chromium, and the state expects a new MCL will be adopted by September 2019.2

As the water industry saw in the 10 years immediately following the lowering of the arsenic MCL, technologies have already begun to hit the marketplace for hexavalent chromium, and many of them show great promise for lowering the cost of compliance for the future hexavalent chromium MCL.

Technology Innovations

When California established the original MCL for hexavalent chromium on July 1, 2014, the rule identified reduction coagulation filtration, ion exchange, and reverse osmosis as best available treatments. Initially, costs in California for treatment were estimated to range from as little as $300 per acre-foot for a 1,500-gpm well to as much as $2,600 per acre-foot for a 100-gpm well (Seidel et al., 2013).

Since the 2014 initial MCL, several technology innovations have been under development that have potential to significantly reduce the costs of compliance. Potentially, the most dramatic reduction in treatment costs may have been identified by Coachella Water District during bench testing of its treatment system. In a report to the District Board on June 27, 2017, Steve Bigley, director of environmental services, identified that after using stannous chloride as a reducing agent in bench test, hexavalent chromium stayed in a reduced condition as trivalent chromium in the presence of free chlorine for up to 15 days. Many systems could potentially treat for the presence of hexavalent chromium by simply adding a single chemical without the need for filtration. The District is planning to carry out a full-scale demonstration of the treatment concept to see if the chrome stays in the reduced form in the real-world conditions of the distribution system. With a change in oxidation conditions, impacts on lead levels will also need to be investigated, but the potential cost savings of this approach are tremendous, effectively eliminating the need for filtration and residuals handling and disposal.

Since the 2014 initial MCL, several technology innovations have been under development that have potential to significantly reduce the costs of compliance.

Another treatment innovation, using a simplified reduction, coagulation, and filtration process, has been conducted at the Cadiz, Inc. property in San Bernardino County, CA. Pilot testing has been completed, and a six-month demonstration study is underway at the site. The treatment system uses ferrous chloride reduction and air injection in pipeline contactors, followed by pressure filtration to simplify and reduce the capital and operations costs of reduction/coagulation/filtration.

Cadiz Water Supply Project

Cadiz, Inc. (Cadiz) is a private corporation that owns approximately 34,000 mostly contiguous acres in the Cadiz and Fenner Valleys (Cadiz Property), which are located in the Mojave Desert portion of eastern San Bernardino County, CA.

Cadiz, in collaboration with other water providers participating in the project, has collaboratively developed the Cadiz Valley Water Conservation, Recovery, and Storage Project to implement a comprehensive, long-term groundwater management program for the closed groundwater basin underlying its property that would allow for both the beneficial use of the groundwater and storage of imported surface water in the groundwater basin.

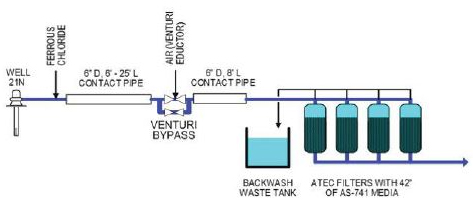

Figure 1. ATEC pilot filter schematic

Underlying the Cadiz and Fenner Valleys and the adjacent Bristol Valley is a vast groundwater basin that holds an estimated 17 to 34 million acre-feet (MAF) of fresh groundwater. The project area, which would be sited on Cadiz Property, is located at the confluence of the Fenner, Orange Blossom Wash, Bristol, and Cadiz watersheds (Watersheds), which span over 2,700 square miles.

Figure 2. ATEC pilot filters within the trailer

Within this closed basin system, groundwater percolates and migrates downward from the higher elevations in the Watersheds and eventually flows to Bristol and Cadiz Dry Lakes. The Dry Lakes represent the low point in the closed watershed basin, meaning that all surface and groundwater within the surrounding Watersheds eventually flows down gradient to these Dry Lakes areas and not beyond. Once the fresh groundwater reaches the Dry Lakes areas, it evaporates, first mixing with the highly saline groundwater zone under the Dry Lakes and getting trapped in the salt sink — no longer fresh, suitable, or available to support freshwater beneficial uses. The portion that evaporates is lost from the groundwater basin and is therefore also unable to support beneficial uses.

Cadiz Pilot Testing — Phase 1

Pilot testing was conducted with a vendor-supplied system: ATEC Water Treatment System’s manganese dioxide pressure filters. Initial testing was conducted to assess the applicability of the technology to Cadiz groundwater. Subsequent pilot tests were conducted to assess efficacy of the treatment process for a range of operating conditions as described below.

A schematic drawing of the pilot test equipment used in this study is shown in Figure 1. Figure 2 shows the pilot trailer. The pilot system consisted of the following:

- Ferrous chloride injection followed by a 6-inch-diameter, 6- to 25-foot-long contact pipe;

- Air eduction through a venturi eductor followed by a 6-inchdiameter, 8-foot-long contact pipe; and

- Four 6-inch-diameter cylindrical filters, each containing approximately 0.6 cubic foot of ATEC 741 (trade name) manganese dioxide media

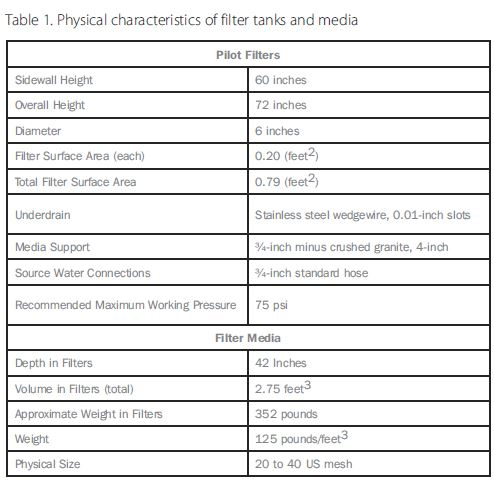

Figure 2 shows a photograph of the pilot filters inside the ATEC trailer. The pilot filter consisted of four 6-inch filter columns connected by common manifolds for influent, effluent, and backwash water. Each filter was controlled by a three-way ball valve. Source water was metered using a totalizing flow meter. Pressure was measured on the influent and effluent manifold to determine head loss. Manganese dioxide granules (pyrolusite) were used as filter media. The media has been certified through NSF Standard 61 as being suitable for drinking water applications. Details on the filtration tanks and media are presented in Table 1.

Ferrous chloride was added to the well water using a stock solution of ferrous chloride diluted to 1,700 mg/L and dosed using a peristaltic feed pump. The concentration of the diluted ferrous chloride stock solution was determined through field measurements, and the feed pump flow rate was controlled to maintain the desired dose at the raw water injection point.

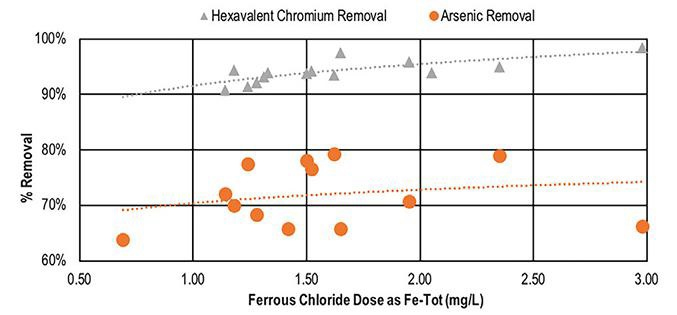

Figure 3. Cadiz hexavalent chromium and arsenic removal at various ferrous chloride doses

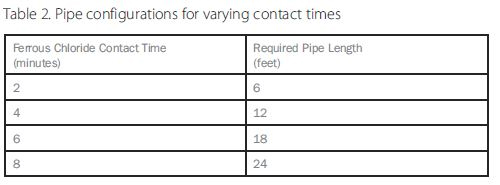

Sections of 6-inch PVC contact pipe were connected with mechanical joints for simple modification of the contact pipe length. The lengths for the tested contact times are presented in Table 2.

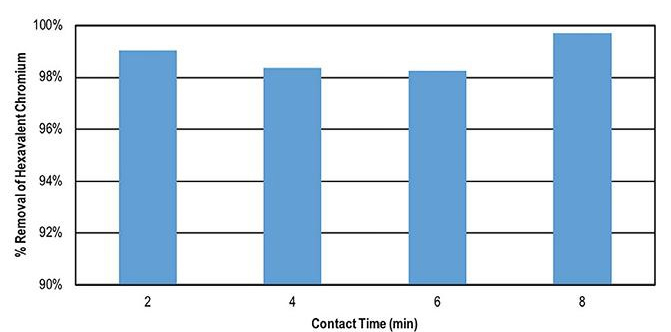

Figure 4. Cadiz average hexavalent chromium removal at varied contact times

Air injection was achieved using a ½-inch Model 0484 Mazzei injector and a 1-inch ball valve to control the bypass water flow rate. Maximum air injection was reached by closing the eductor bypass valve fully and pushing 100 percent of the flow through the ½-inch eductor and increasing the pressure differential. Pressure differential across the eductor was maintained between 10 and 25 psi by adjusting the bypass valve position. Dissolved oxygen was measured periodically in the filter effluent.

Pilot Testing Results — Phase 1

CH2M conducted the pilot testing together with ATEC Systems, Inc. (ATEC). James Borchardt of Stantec, Inc. provided recommendations for comprehensively testing the efficacy of the treatment process across a range of operating conditions. The tests were conducted from Aug. 24 to 27, 2015, from Sept. 9 to 10, 2015, and from Nov. 19 to 20, 2015 using raw water supplied from Cadiz Ranch Well No. 21N.

Pilot testing showed that a ferrous chloride dose of 1.5 mg/L (as iron) was needed to achieve 90 percent removal of hexavalent chromium, as shown in Figure 3. Arsenic removal of approximately 70 percent was achieved simultaneously.

Ferrous chloride contact times of 2, 4, 6, and 8 minutes were tested as well, as shown in Figure 4. The pilot testing showed that 2 minutes of reaction time was sufficient for effective hexavalent chromium removal. All four tested contact times provided efficient hexavalent chromium removal without a clear trend. Shorter contact times could be tested in the future to determine the minimum time required to achieve substantial chromium reduction.

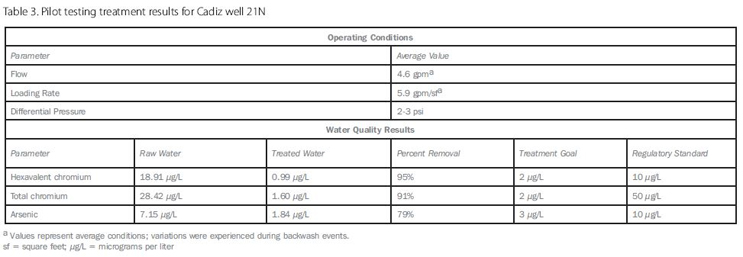

A summary of the testing results is presented in Table 3. Raw water quality and finished water quality results are all from Eurofins Eaton Laboratory, Monrovia CA.

Table 3 lists the average treatment results across all scenarios tested using the ATEC system. Note that these numbers include samples taken after breakthrough and immediately following filter backwash. The system was able to meet the Cadiz treatment goals for hexavalent chromium and total chromium, which are significantly lower than the regulatory limits. For all the treated water pilot testing results, 68.2 percent of the total chromium tests and 93.2 percent of the hexavalent chromium tests were below the treatment goal of 2 μg/L. The treatment goals are not a limit on treatment opportunities using the reduction, coagulation, filtration (RCF) process and potentially could be reduced further based on findings of this pilot testing.

Arsenic was already below the regulatory level of 10 μg/L, but some reduction in arsenic was also achieved to a level below the established treatment goal. For all treated water arsenic tests collected during pilot testing, 70.5 percent were below the treatment goal of 3 μg/L for arsenic.

Pilot Testing — Phase 2

A six-month pilot test of a 100-gpm treatment system was begun at the Cadiz site in April 2018. The system includes five 24-inch diameters, along with pipeline contactors constructed by ATEC Systems (Hollister, CA). Figure 5 shows the filters installed at the site.

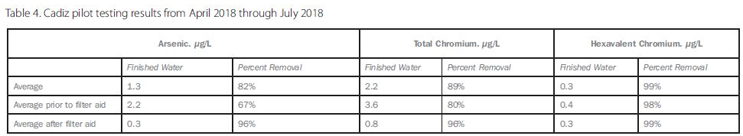

Preliminary results of the Phase 2 pilot testing are shown in Table 4. The results presented are through the first four months of the six-month pilot test. A nonionic filter aid polymer was tested as part of the pilot study. The filter aid was dosed at a concentration of 0.015 mg/L. The filter aid improved the removal of both the arsenic and total chromium.

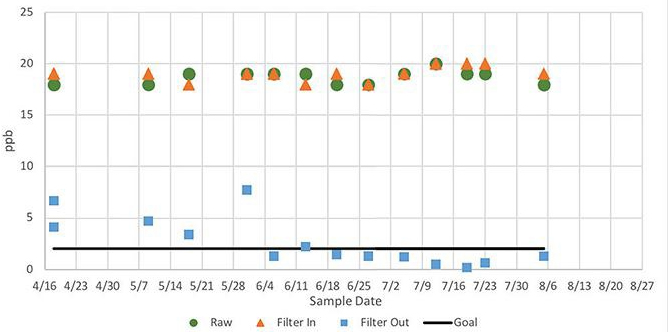

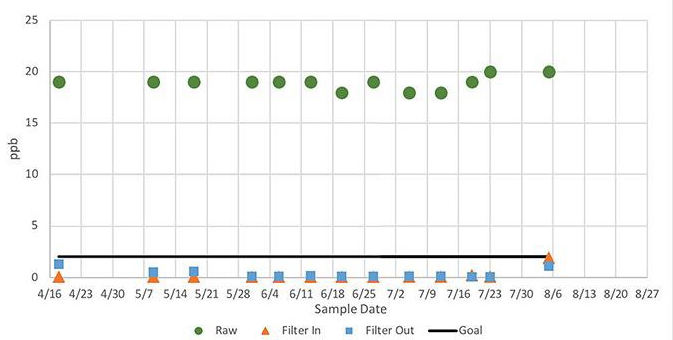

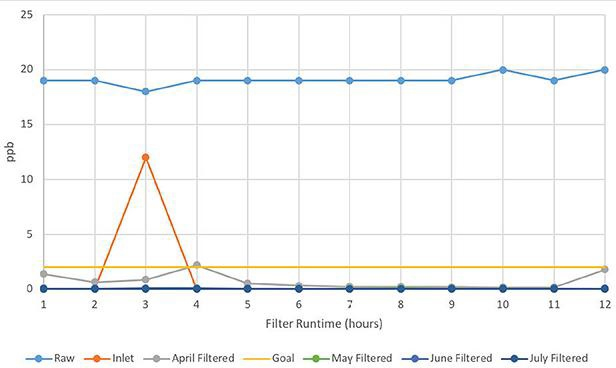

Samples were collected on a weekly basis from the pilot test. The pilot operates 24 hours per day, continuously, and backwashes every 12 hours. The results of weekly testing for total chromium and hexavalent chromium are shown in Figures 6 and 7. Filter flow, backwash flow, and system pressure data is logged every 5 minutes on a data logger. Samples are also collected on an hourly basis each month for a 12-hour filter run. The results of the hourly testing for hexavalent chromium through July 2018 are shown in Figure 8.

Conceptual Design Of Treatment Facility

The proposed treatment methodology is the use of the RCF process. The process will use ferrous chloride to reduce hexavalent chromium to trivalent chromium. This is followed by the introduction of air to oxidize low levels of iron that are also present in the water. The iron and trivalent chromium precipitates are then removed by filtration using a manganese dioxide-coated media.

The typical ferrous chloride dose will be 1.5 mg/L, although the system will be designed for feeding up to 3.0 mg/L. The ferrous chloride will be purchased as a bulk liquid, delivered by tank trucks. Two 6,000-gallon storage tanks will be provided for each treatment plant, with each one capable of receiving a full truckload delivery when it is nearly empty. The ferrous chloride will be fed into the pipeline using hose-type metering pumps. Two pumps will be provided, with each pump capable of meeting 100 percent of the need.

Figure 5. 100-gpm pilot testing system at Cadiz site

Air will be introduced by withdrawing a sidestream of water, raising the pressure with a pump, and passing the higher-pressure water through a venturi inductor. This will entrain air, and then the sidestream will be injected back into the transmission pipeline. A 2-minute contact time will be provided after the air addition and before water enters the filters, to allow for oxidation of iron. The air injection system consists of a pump to increase the pressure of the sidestream before running it through a venturi inductor. A spare pump will be provided to make for a reliable system.

Figure 6. Total chromium results in 100-gpm Cadiz pilot testing – April 2018 through July 2018

The individual filter vessels will be grouped in filter banks of 10 vessels. A filtration rate of 6.0 gpm per square foot (gpm/sf) was used as the basis for selecting the number of filter banks. The proposed plant layout is shown in Figure 9. The multiple individual filters provide built-in redundancy because if it is necessary to remove a bank of filters, other filters can be operated for short periods at higher filtration rates to allow for continuous production.

Figure 7. Hexavalent chromium results in 100-gpm pilot testing at Cadiz – April 2018 through July 2018

Water from the South Wells will be delivered through a 30-inchdiameter transmission line to the South Water Treatment Plant (WTP). Water from the North Wells will be delivered through a 54-inchdiameter transmission line to the North WTP.

Residuals Handling

Reduction/coagulation/filtration produces an iron sludge that can be dewatered and landfilled. The landfilled sludge cannot leach more than 5 mg/L of chromium in the Toxic Contaminant Leachate Potential (TCLP) test or the Waste Extraction Test (WET) in California.

Backwash water will be directed to settling ponds on-site and settled water will be recycled to the head of the treatment plant. Solids will be dried in the basins on a rotating basis and disposed of year-round.

Figure 8. Hexavalent chromium removal during 12-hour filter runs – April 2018 through July 2018 (hourly)

Cost Estimates

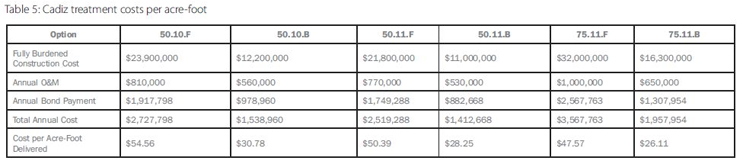

Capital costs and annual O&M costs were developed for a variety of scenarios ranging from blended treatment and delivery of 50,000 acre-feet per year over 10 months (50.10.B) to full treatment with delivery of 75,000 acre-feet over 11 months per year (75.11.F). Capital expenditure (CAPEX) estimates were developed using vendor-supplied quotes and CH2M’s internal water treatment estimating software (CPES). They include sales tax at 7.75 percent. Operating expenditure (OPEX) costs account for electricity, chemicals, lab analyses, property taxes, maintenance, and labor. The costs per acre-foot are shown in Table 5. These costs do not include nonconstruction costs such as design and do not include contingencies. The O&M costs do not include residuals disposal costs.

Figure 9. Conceptual drawings of the Cadiz water treatment facility, at full capacity for 75,000 acre-feet per year delivery

As the six-month demonstration test is completed and the costs of operations are refined, including disposal costs, the cost per acre-foot will likely increase, but will remain well below the initial estimates of hundreds of dollars per acre-foot.

References

1Bigley, Steve, June 27, 2017 Update on the Chromium-6 Alternative Treatment Pilot Testing Project, Coachella Water District Board Meeting. http://sire.cvwd.org/cache/2/nd2zqzebgiqibnx1zuywnbge/9011211212017074129917. PDF (Accessed November 21, 2017).

2Blute, N.K.; Wu, X.; Porter, K.; Imamura, G.; & McGuire, M.J., 2013. Hexavalent Chromium Removal Research Project Report. Submitted to California Department of Public Health. www.glendalewaterandpower.com/about/chromium6_report_appendices.aspx(Accessed August 5, 2013).

3Blute, N.; Wu, X.; Visosky, T.; & DeWolfe, J., 2012. Hexavalent Chromium Treatment Residuals Management. Association of California Water Agencies. www.acwa.com/sites/default/files/news/water-quality/2012/04/acwa-cr6-report-final-appendices-032712_1.pdf(Accessed August 5, 2013).

4Edwards, M. & Benjamin, M.M., 1989. Adsorptive Filtration Using Coated Sand: A New Approach for Treatment of Metal-Bearing Wastes. Journal of the Water Pollution Control Federation, 61:9:1523.

5Drago, J.A., 2001. Technology and Cost Analysis for Hexavalent Chromium Removal from Drinking Water Supplies, AWWA Water Quality and Technology Conference, Nashville, TN.

6Lee, G.H. & Hering, J.G., 2005. Oxidative Dissolution of Chromium(III) Hydroxide at pH 9, 3, and 2 with Product Inhibition at pH 2. Environmental Science & Technology, 39:13:4921.

7McGuire, M.; Blute, N.; & Qin, G., 2007. Hexavalent Chromium Removal Using Anion Exchange and Reduction With Coagulation and Filtration. Water Research Foundation Report 91193, Denver.

8McGuire, M.; Blute, N.; Seidel, C.; Qin, G.; & Fong, L., 2006. Pilot-Scale Studies of Hexavalent Chromium Removal From Drinking Water. Journal AWWA, 98:2:134.

9OEHHA (Office of Environmental Health Hazard Assessment), 2011. Public Health Goals for Chemicals in Drinking Water: Hexavalent Chromium (Cr VI). California Environmental Protection Agency. http://oehha.ca.gov/water/phg/pdf/Cr6PHG072911.pdf(Accessed August 5, 2013).

10Chad J. Seidel, Issam N. Najm, Nicole K. Blute, Christopher J. Corwin, and Xueying Wu, National and California treatment costs to comply with potential hexavalent chromium MCLs Journal AWWA http://dx.doi.org/10.5942/jawwa.2013.105.0080(AccessedNovember 13, 2017).

11Seidel, C.J. & Corwin, C.J., 2013. Total Chromium and Hexavalent Chromium Occurrence Analysis. Journal AWWA, 105:6:E310. http://dx.doi.org/10.5942/jawwa.2013.105.0050 (Accessed November 13, 2017).

12Sharma, S.K., Petrusevski, B. & Amy, G., 2008. Chromium Removal from Water: A Review. Journal of Water Supply: Research and Technology - AQUA, 57:8:541.

About The Authors

Lee H. Odell is a global technologist for Jacobs Engineering, specializing in groundwater treatment. He is the chair of the water supply, treatment and distribution system engineering for the American Society of Civil Engineers. He has been a consulting engineer for 29 years and lives in Portland, OR.

Lee H. Odell is a global technologist for Jacobs Engineering, specializing in groundwater treatment. He is the chair of the water supply, treatment and distribution system engineering for the American Society of Civil Engineers. He has been a consulting engineer for 29 years and lives in Portland, OR.

Bill Ketchum is president of ATEC System Associates, specializing in developing cost-effective groundwater treatment solutions for iron and manganese, radium, arsenic, chromium, and other compounds. ATEC Systems Associates manufactures their own filter equipment in Hollister, CA, and Bill resides in Bainbridge Island, WA.

Bill Ketchum is president of ATEC System Associates, specializing in developing cost-effective groundwater treatment solutions for iron and manganese, radium, arsenic, chromium, and other compounds. ATEC Systems Associates manufactures their own filter equipment in Hollister, CA, and Bill resides in Bainbridge Island, WA.