Handbook of Chlorination and Alternative Disinfectants, Fourth Edition

(page 62)

A June 1996 development has affected the use of 150-lb and ton cylinders in the arid western states. This is the requirement of sealed total containment vessels for these chlorine cylinder containers instead of airtight rooms with chlorine scrubbers. The makers of these patented containers, TGO Technologies, Santa Rosa, California, have already sold 20 units.

(begins on page 783)

Effect of the Uniform Fire Code

TGO Technologies

100- and 150-lb Cylinders. These cylinders can now be installed and operated in and from a total containment vessel to comply with the latest revision of the California Fire Code, Title 24, Part 9, Article 80, adopted in January 1996. This code requires that every chlorination system using chlorine supply cylinders must have a treatment system for mitigating accidental releases of chlorine gas or liquid chlorine.

These systems are required to reduce to 5 ppm the atmospheric chlorine concentration in the area surrounding the accidental leak before diverting the release to the external atmosphere.

The TGO Technologies containment vessels eliminate the need for costly scrubber systems. Since accidental chlorine emission from either a 100- or a 150-lb container is extremely rare, this option can be expected to be very popular, given that the containment vessel and its accessories generally cost no more than about $25,000 per installation.

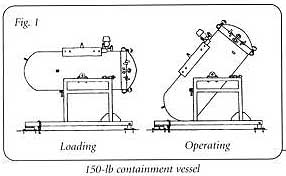

The containment vessel installation is illustrated in Fig. 1 for both 100- and 150-lb chlorine or sulfur dioxide cylinders. These installations should be made so that the containment vessel is never subjected to sunlight or rain.

(page 786)

Ton Cylinders. This type of chlorine cylinder containment arrangement is pictured in Fig. 2, showing the truck off-loading requirement adjacent to the containment vessel (click here for pic and next page of text). The ton chlorine and sulfur dioxide cylinders are also subject to compliance with the January 1996 issue of the California Fire Code Article 80, Title 24, Part 9. These treatment systems are required to reduce the concentration of either gas in the enclosed area of the leak to 5 ppm before it is released to the external atmosphere. Article 80 of the California Code allows the option of using total containment vessels for ton cylinders.

This cylinder containment facility requires a specially designed truck unloading platform, so that the ton cylinder can be rolled into place in the high pressure containment vessel that encloses the ton cylinder.

In the event that the chlorine cylinder develops a leak (either gas or liquid Cl2), the chemical will all be contained within the containment vessel. There are automatic chemical-sensing shut-off valve assemblies mounted at the vessel port on the containment vessel. This valve system allows for a low, controlled rate of leak evacuation flow from the containment vessel. This prevents the escape of any toxic gas or liquid from the chlorine cylinder into the environment.

As mentioned previously for 150-lb cylinders, the controlled-leak-rate evacuation from the containment vessel allows for elimination or reduction of the large scrubber systems for disposal of such a leak, which is normally needed to handle a high-volume leak rate.

Several of these units are already in place (1997), and many more are being installed. As TGO Technologies is a Santa Rosa, California firm, it is not surprising that one of the first installations was in November 1996 at the Solano Irrigation District Chalk-Hill water treatment plant.