Greener Pastures Ahead For Pumps

By Michael Michaud

Energy-saving pumps will be ever more present in 2021 as investment in eco-friendly infrastructure continues to grow.

Before we heard “Build back better” as a slogan in the 2020 election, it was a popular catchphrase used by organizations around the world to encourage the improvement — not just replacement — of equipment or critical systems, especially in post-disaster recovery. As water infrastructure continues to receive a D grade on the American Society of Civil Engineers’ (ASCE) Infrastructure Report Card, now is a good time to apply that principle. For years, sustainability has been a prerogative of communities and businesses that have implemented energy-saving solutions, incentive programs, and goals to reduce carbon footprint across a wide range of industries.

Meanwhile, pumps are often overlooked as a key source of energy savings. With today’s advancements in pumps and related equipment, as well as growing support for green infrastructure, 2021 could mark a rise in interest and implementation of energy-saving pump systems.

Why Now?

News out of Washington suggests infrastructure investment is a bipartisan priority. The upcoming appropriation bill could be one of the few pieces of legislation that passes during the lame duck session. There is a growing bipartisan expectation that a historic “infrastructure investment – job creation bill” will be a priority for the Biden administration and the 117th Congress in 2021. Increased funding for water infrastructure will be one of the centerpieces of this legislation. Federal funding for Clean Water Act (CWA) and Safe Drinking Water Act (SDWA) infrastructure, including pumps and pumping systems, will be increased from $2.5 billion annually to over $12 billion annually. Committees in both the House and the Senate are supportive of “green infrastructure” set asides of up to 15 percent. This includes energy-efficient pumps and pumping systems.

Industry experts agree that, nationally, water and wastewater projects will continue to exceed 2018-19 levels over the next 18 to 24 months. Projects in place remain above 2019 numbers, with wastewater projects up 5 percent and water projects up 21 percent. These numbers are expected to hold through 2021, as most projects are on a 12- to 18-month timeline. The long project timeline also means that many of the pumping systems have already been designed.

More Than A Trend: A New Energy-Savings Gold Mine

Pumps can account for 40 percent of energy usage in industrial fluid systems, and when it comes to water infrastructure, investment in energy-saving pumps can go a long way. The U.S. Department of Energy’s 2002 Motor Market Assessment established that pumping systems offer the greatest optimization potential of all types of fluid systems, offering savings of up to 75 percent with an average net savings of over 20 percent. Few other technologies could have as big an impact, and that’s important considering that one of the largest single expense items for a water treatment plant can be its utility bill.

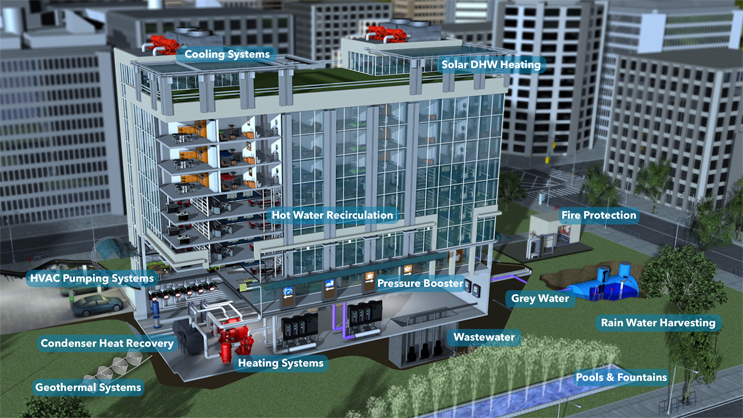

Pumps reside in water and wastewater systems of all types and sizes, using energy to move fluids. While reliability comes first in pump system design, there is obviously a cost savings incentive for stakeholders to improve the energy efficiency of pump systems. Roughly 65 percent of the total cost of ownership for pumps is related to energy and maintenance, while the initial cost of purchasing and installing a new pump accounts for just 10 percent of the total lifetime costs. Utilizing pumps with greater energy efficiency can reduce total cost of ownership for pumps and whole pump systems.

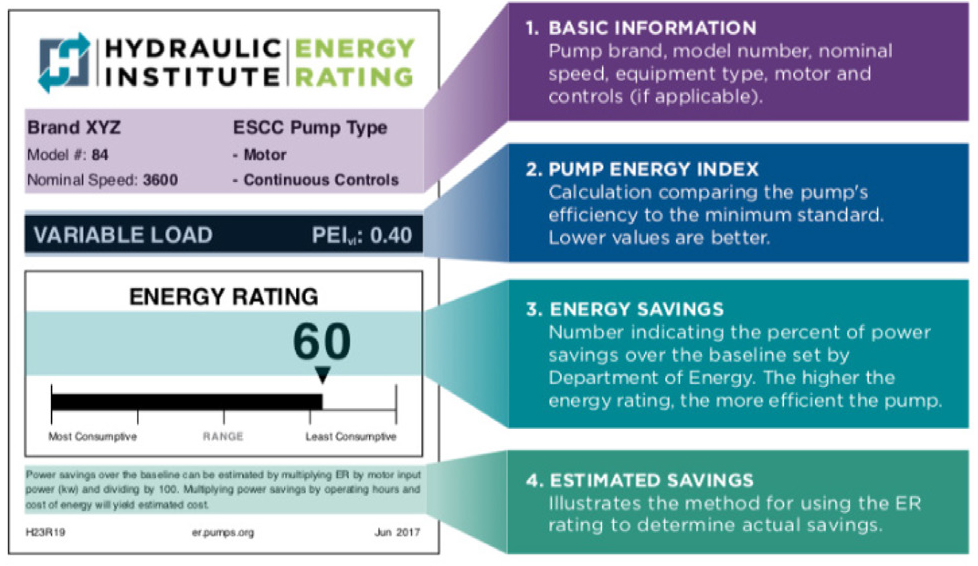

The HI Energy Rating Program allows users to view and verify data on pumps that indicates the power savings obtained from upgrades and changes.

Identifying Opportunities To Gain Efficiencies

One misconception around energy efficiency in pumps is that it has to come at the cost of performance and/or reliability. However, this assumption is incorrect. There is often the opportunity to improve performance, efficiency, and reliability of a system — all in tandem with many pump options, accessories, and best practices to optimize design. Solutions don’t have to be complicated. Sometimes it’s as simple as deciding to utilize smart pumps that integrate a variable frequency drive (VFD) that has the pump performance programmed in from the factory, instead of retrofitting with a separate VFD.

To help identify the most efficient pump(s) for system requirements, the Hydraulic Institute (HI) offers an Energy Rating Program for select pump types below 200 horsepower, as well as its Pump Savings Calculator.1 This tool assists specifiers and end users in determining the most energy- and cost-efficient pump systems for their applications by factoring the impacts of potential energy savings, based on the HI Energy Rating, alongside other variables like initial cost, installation, maintenance, etc. The calculator draws on HI’s Energy Rating (ER) Program2 database of rated pumps to calculate potential energy savings and incremental cost increases for different Energy Ratings available on specific pumps and addons like variable speed controls that can be installed on constant speed pumps.

Make An Energy-Savings Resolution

While more government infrastructure funding would be a nice boost in 2021, there is no need to wait for the incentive to think about “green infrastructure.” The savings from installing efficient pumping systems today will be felt for 20 or more years. We can start building better systems now by installing more efficient pumps and designing more efficient pumping systems. With today’s increased awareness and understanding of energy efficiency, let’s not miss out on the opportunity to build a better system. There may still be time to reexamine the pumping system to ensure it is designed to reduce energy costs.

For more information on the Hydraulic Institute, visit www.pumps.org.

References:

1. https://estore.pumps.org/Energy-Rating-Life-Cycle-Cost-Calculator- Tool-P3263.aspx

2. http://www.pumps.org/EnergyEfficiency/Energy_Rating.aspx

About The Author

Michael B. Michaud is the executive director of the Hydraulic Institute, the largest association of pump industry manufacturers in North America. Since joining HI in 2015, Michaud has expanded the institute’s portfolio of efficiency programs by launching the HI Energy Rating Label and the Pump System Assessment Professional (PSAP) Certification. Prior to joining the Hydraulic Institute, Michaud spent 19 years in leadership positions at the American Society of Mechanical Engineers (ASME), where he was responsible for developing and implementing global strategy, managing the International Gas Turbine and Petroleum Institutes, and growing professional development and training activities around the world.

Michael B. Michaud is the executive director of the Hydraulic Institute, the largest association of pump industry manufacturers in North America. Since joining HI in 2015, Michaud has expanded the institute’s portfolio of efficiency programs by launching the HI Energy Rating Label and the Pump System Assessment Professional (PSAP) Certification. Prior to joining the Hydraulic Institute, Michaud spent 19 years in leadership positions at the American Society of Mechanical Engineers (ASME), where he was responsible for developing and implementing global strategy, managing the International Gas Turbine and Petroleum Institutes, and growing professional development and training activities around the world.