From Theory To Precision: ORP Monitoring As The New Standard In Water Treatment

By Emma Flanagan

On numerous levels, oxidation-reduction potential (ORP) outperforms the presently predominant metric for evaluating disinfection performance.

Ensuring microbiological safety in water systems is a top priority for municipal utilities, healthcare facilities, food processing, and industrial operations. Two widely recognized methods for assessing and controlling disinfection performance are the CT (concentration times time) method and oxidation-reduction potential (ORP) monitoring. While the CT method has long served as a regulatory benchmark, ORP monitoring offers a more dynamic, real-time, and integrated approach to managing water quality — especially in systems where precision and adaptability are critical.

Understanding CT Monitoring: Strengths And Limitations

For many years, operators have relied on the CT method to evaluate the success of their disinfection efforts. CT is determined by multiplying the disinfectant concentration (C) in mg/L by the contact time (T) in minutes. This product yields a numerical value used to assess whether the water treatment process meets established regulatory thresholds for pathogen inactivation. These thresholds vary depending on variables like water temperature and pH. For instance, achieving a 3-log (99.9%) reduction of Giardia at pH 7 and 10° C with free chlorine typically requires a CT value around 90 mg-min/L.

While CT remains foundational and regulatory in nature, its limitations become increasingly pronounced in dynamic or complex water systems. CT assumes steady-state conditions and requires detailed hydraulic modeling. It produces only a momentary snapshot of water quality based on periodic measurements. These values don’t reflect how real-world water chemistry, such as organic load or fluctuating pH, can weaken or neutralize the efficacy of disinfectants. CT calculations also involve several interdependent variables, such as temperature, flow rate, and baffling factors, many of which may not be stable or accurately measurable in live systems. Because CT values must be evaluated after the fact, they offer little support for immediate decision-making or timely corrective action.

The method is inherently static. It reflects water quality conditions at the time of sampling but fails to capture fluctuations in flow, disinfectant residual, or temperature between data points. These information gaps can lead to inaccurate conclusions. Moreover, CT relies on complex calculations and precise instrumentation. Operators must assess effective contact volumes, system hydraulics, and baffling efficiency to derive meaningful CT values. Even with accurate data, this process is time-consuming and not well suited to real-time decision-making. CT is also pathogenspecific. Different organisms require different CT thresholds for inactivation. Operators must constantly adjust for potential threats, complicating the disinfection strategy. Finally, CT does not account for the strength of the oxidative environment or the presence of organic matter that can consume disinfectants before they contact pathogens.

Reading The Water’s Pulse: ORP Fundamentals For Smarter Monitoring

ORP offers a radically different and more modern approach. Measured in millivolts (mV), ORP quantifies the water’s tendency to either donate or accept electrons. In practical terms, it assesses the water’s ability to oxidize contaminants such as bacteria, viruses, and protozoa. Unlike CT, which only captures theoretical dose and time exposure, ORP integrates the full range of oxidative and reductive influences in a water system. It reflects changes in pH, disinfectant type, temperature, and organic load — all of which influence disinfection strength.

Higher ORP values correspond with stronger disinfection potential. Research consistently shows that ORP levels above 650 to 700 mV are sufficient to inactivate a wide array of pathogens, including E. coli and Legionella pneumophila. Whereas CT calculates disinfection performance using indirect inputs and assumptions, ORP delivers real-time, direct feedback about actual water-quality conditions. This immediacy enables operators to make timely adjustments to chemical dosing, detect contamination risks as they develop, and maintain stable disinfection performance even in systems with variable water conditions.

What distinguishes ORP is its ability to reflect the total oxidative condition of the water. This is not limited to the presence of disinfectants — it also includes the impact of organic contaminants and reducing agents, such as ammonia, iron, and manganese. If these substances begin to deplete available oxidants, ORP will drop, alerting operators to diminished disinfection efficacy. CT monitoring offers no such real-time alert. Its reactive nature often results in problems being discovered only after the fact, when test results fail to meet standards.

ORP is also simpler to implement. It eliminates the need for manual CT calculations, complex modeling, or laboratory analysis. ORP sensors continuously stream data to digital interfaces and can be integrated into automated control systems. When ORP levels fall below a predetermined set point, chemical dosing can be automatically adjusted to restore optimal disinfection. This closed-loop feedback mechanism is ideal for facilities that require consistent and adaptable water-quality control.

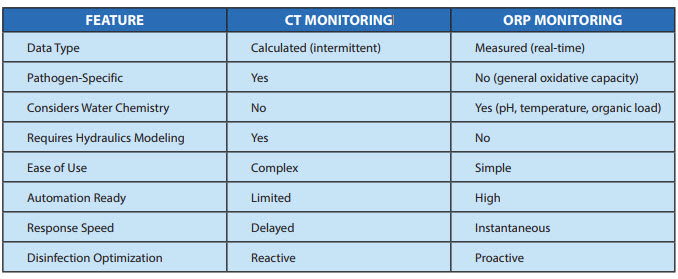

CT vs. ORP: Side-by-Side Comparison

Operationally, ORP offers several other advantages. It requires no calculations — operators simply read the sensor value. There is no need for contact tank modeling or estimation of baffling factors. This reduces training burdens and the risk of user error. ORP is also highly compatible with automation. Sensors can communicate with control systems and chemical dosing equipment, dynamically responding to spikes in contamination or changes in water chemistry. This precision reduces the need for over-dosing, conserves chemicals, and limits the formation of disinfection byproducts. In terms of microbial control, ORP provides a more predictive indication of performance. Research has shown that ORP levels reliably correlate with microbial inactivation across various disinfection agents, not just chlorine. Pathogens like Legionella respond more consistently to the oxidative strength of the environment than to calculated CT exposure, especially when biofilms are involved.

Time To Set A New Gold Standard — Here’s Why

Although CT still dominates regulatory frameworks, particularly under the U.S. EPA Surface Water Treatment Rules, many facilities are shifting toward ORP for operational control. Hospitals, food production plants, and cooling-tower systems are increasingly using ORP thresholds as either a supplement or replacement for CT, particularly in environments where disinfection must be uninterrupted and highly effective. ORP’s real-time nature is particularly valuable in systems prone to biofilm development or where oxidant-resistant pathogens may be present. Legionella, for example, often thrives in conditions where CT values suggest adequate disinfection, but oxidative strength is insufficient.

The ability to measure actual oxidative power rather than theoretical exposure time also supports better chemical management. CT-based disinfection often leads to overdosing as a buffer against uncertainty, which raises costs and increases byproduct formation. ORP-driven dosing strategies can maintain disinfection reliability while improving efficiency and sustainability.

In a side-by-side comparison, CT provides a retrospective, theoretical assessment based on ideal assumptions. ORP offers a forward-looking, real-time measurement grounded in actual water chemistry. For operators focused on preventing outbreaks, meeting compliance targets, and modernizing water-system management, ORP represents a superior method of monitoring.

Though CT remains embedded in regulatory protocols, ORP is increasingly recognized as the gold standard for practical, continuous monitoring. Facilities managing cooling towers, reclaimed water systems, and healthcare plumbing are setting ORP thresholds — often above 650 mV — as operational targets that ensure water remains disinfected regardless of CT data availability or variability.

In modern water systems where flow rates, temperatures, and contaminant loads can shift unpredictably, operators need more than theoretical models. They need real-time, integrative data to ensure water safety. ORP provides that insight. It empowers operators to respond with precision, manage risks proactively, and reduce reliance on outdated assumptions.

While CT monitoring has laid the groundwork for water disinfection standards, ORP delivers the clarity, speed, and adaptability that today’s systems demand. Its adoption marks a shift toward smarter, more resilient, and data-informed water-treatment practices — ones that align with both operational efficiency and public health protection.

About The Author

Emma Flanagan is the CEO/CTO of Envirocleen, LLC, an Illinois water treatment consulting company, manufacturer, and distributor of mineral oxychloride advanced oxidation reagent and quantum disinfection technologies. Email: info@envirocleen.com

Emma Flanagan is the CEO/CTO of Envirocleen, LLC, an Illinois water treatment consulting company, manufacturer, and distributor of mineral oxychloride advanced oxidation reagent and quantum disinfection technologies. Email: info@envirocleen.com