Free Ammonia Control

By Chip Bettle, Co-Inventor, Blue Frog Patented Technology

The city of Royston is a town located in Franklin County, Georgia. The city is currently operating a wastewater treatment plant that is a two-pond lagoon treatment system.

The patented Blue Frog Technology was installed nearly three years ago to digest sludge in situ. The superintendent (Butch) uses a blue dye that blocks light and inhibits blue-green algae growth. Today the City of Royston has no blue-green algae or sludge, simplifying the ammonia algorithm.

The Environmental Protection Agency (EPA) has recently published final guidance on acute and chronic ammonia in wastewater effluents. EPA recognizes that un-protonated ammonia (free ammonia (NH3-N)) is toxic; and protonated (NH4+-N) is not toxic to most water invertebrates. Thus, it is important to understand how free ammonia is controllable.

In wastewater lagoon systems, typical of small town treatment systems, the ammonia typically enters as protein from human waste. The protein is broken down and eventually ammonia (NH3-N & NH4+-N) enters the pond.

Ammonia is removed 7 ways:

- Ammonia is oxidized to nitrate and then reduced to gas.

- This pathway is temperature and oxygen dependent and takes place on aerated attached growth media.

- Ammonia accumulates in biosolids as "inventory".

- Mechanical dredging occurs periodically.

- Biosolids (sludge) are then land applied or disposed of in a landfill.

- Ammonia leaves the pond as organic-N in algal and TSS body mass.

- Summertime removal is higher because algae bloom in warm water.

- Algae blooms increase pH and increase free ammonia.

- Free ammonia is volatile and can be stripped from the water column by produced methane.

- Gas from digesting sludge in situ removes more ammonia than is produced by digesting the biosolids.

- Small amounts of ammonia can be sequestered as solid crystals (e.g. struvite)

- Aerobic worms convert TSS and ammonia into high organic-N silt (that either settles or is discharged as TSS).

- Free ammonia is reduced

- Ammonia is discharged dissolved in the effluent.

- This metric is the EPA control measure.

Free ammonia is influenced by temperature and pH. During the winter months, water has less free ammonia. And low pH water has less free ammonia.

Nature also uses ammonia as a primary control in digesting sludge in situ. There are two pathways to make methane. The H2 pathway consumes extra acid (raising the pH and thus 2 raising free ammonia) but can make stinky sulfur smells from excess H2. The No‐H2 pathway consumes less acid (lowering the pH and thus lowering free ammonia).

High free ammonia in bottom-dwelling hydrolytic brine inhibits the H2 pathway more than it inhibits the No‐H2 pathway. Thus, allowing ammonia to accumulate in the deep end of a pond reduces free ammonia (and sulfur odors):

- Sludge is digested in situ, eliminating the "inventory."

- Produced gas strips ammonia and alkalinity from the water column.

- Brine ammonia selects for the No-H2 pathway, reducing pH, reducing free ammonia and reducing alkalinity needed by algae to grow.

- Reduced alkalinity and reduced ammonia inhibit algae growth and encourage zooplankton grazing of microalgae and TSS.

- The water clears and oxygen are available to bottom-dwelling worms.

Free ammonia control is complex. But it is less complex if there is no sludge in the system and if there are no algae to increase pH.

Documented Results:

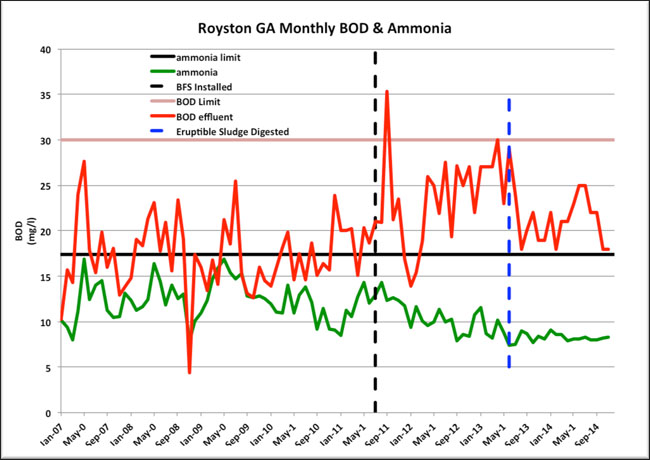

The chart for Royston plots a 7‐year history for BOD (red) and total ammonia (green). The black vertical line is the start-up of Blue Frog System. The dotted blue line is the month the pond was "clean" (no organic sludge on bottom or berm). The horizontal lines are the total ammonia permit limit and the BOD permit limit.

Prior to the BFS installation, BOD and ammonia wobbled up and down, but best fit lines are flat.

After start-up, BOD increased and ammonia declined until the pond was clean. Once the pond was clean, there was a step reduction in BOD and the ammonia was flat during both warm and cold weather.

When the BFS started up, granules form that convert TSS into gas (3CH4 + 1CO2). The rising gas occludes to TSS and brings BOD‐rich solids to the surface where some is discharged. BOD steadily increased during sludge inventory digestion. Ammonia was released as sludge inventory was digested, increasing ammonia. However, free ammonia migrated inside the gas bubbles and was brought to the surface and discharged to the atmosphere. Total ammonia declined indicating that the stripping process removed more ammonia than digestion produced.

Then in June 2013, the pond was clean. Gas production dropped as all inventory was digested and only incoming BOD was turned into gas. The pH stabilized at 7.4 (data not shown), stabilizing the free ammonia. Total ammonia entering the system was "constant" because there was no net change in bioaccumulation of organic-N and no algae-N removal. Total ammonia was constant throughout warm and cold weather @ 8.3 mg/L. Warmer water increased volatile free ammonia, but produced gas stripped it away as it formed.

The EPA 30-day toxicity limit is 1.9mg/l total ammonia @ 7.0 pH and 20°C, or 0.0076 mg/L NH3-N. Royston's total ammonia @ 8.3 mg/L, 12°C, and 7.4 pH is 0.0448 mg/L NH3-N.

Adding more attached growth aerated media can further reduce free ammonia.

Digesting sludge in situ significantly reduces the steady state free ammonia once the pond is clean.

A joint development for wastewater technology requires three key commitments:

- A city’s water/wastewater superintendent and a city’s leadership team that is committed to promoting sustainability resulting in reducing overall costs.

- Two-way communication and data sharing to understand and be proactive to resolving any issues before a crisis occurs.

- A continued partnership that results in minimizing ongoing costs long-term to achieve project objectives.

About the author:

Chip Bettle is co-inventor and executive vice president of engineering for Absolute Aeration, LLC in Greeley, CO. Chip is a chemical engineer who utilizes his unique perspective, straddling both science and engineering, to lead Absolute Aeration in process development. Chip designs complex, low cost solutions to meet regulated discharge requirements. As an inventor he has over 35 approved U.S. patents.

Contact information for Royston, GA:

James “Butch” Watson, Water Department Manager. Butch can be contacted at (706) 245-6472 or e-mail royston6472@bellsouth.net.