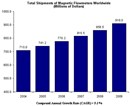

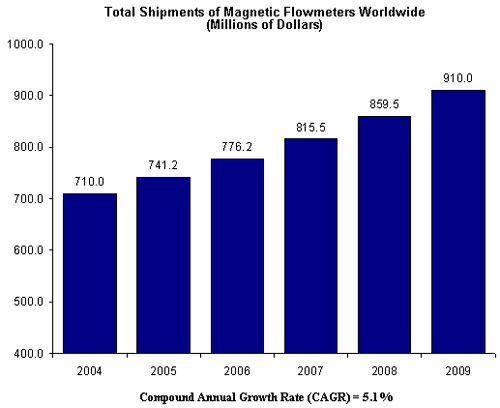

Flow Research Study Finds Fast-Growing Magnetic Flowmeter Market

In many applications, magnetic flowmeters are displacing traditional technology meters, including differential pressure (DP), positive displacement, and turbine meters. Unlike positive displacement and turbine meters, magnetic flowmeters do not have moving parts that are subject to wear over time. And unlike DP flowmeters, magnetic flowmeters do not use a primary element to cause a constriction in the flowstream. The use of a primary element can cause significant pressure loss, and primary elements are themselves subject to wear. With no moving parts and little pressure loss, magnetic flowmeters offer reliability and low cost of ownership.

Dr. Jesse Yoder, president of Flow Research, explains the growth in the magnetic flowmeter market as follows: "Customers are selecting magnetic flowmeters due to their accuracy and reliability. They are also taking advantage of a number of technological improvements to magnetic flowmeters made in the past few years. These include improvements in high-strength DC meters, accuracy enhancements, the increased availability of 2-wire meters, and the introduction of more types of magnetic flowmeter liners. In addition, more companies are now offering insertion meters, which enable magnetic flowmeters to measure flow in large pipes. They are a highly trusted flowmeter for liquid applications."

With all of their advantages, the primary limitation of magnetic flowmeters is their inability to measure the flow of nonconductive fluids. Suppliers have made progress in this area, bringing out magnetic flowmeters that can operate successfully in liquids with very low conductivity values. But despite this, magnetic flowmeters cannot measure the flow of gas or steam. Even so, magnetic flowmeters remain the meter of choice for a broad range of liquid applications.

SOURCE: Flow Research, Inc.