Evolution In Wastewater Goes With The Flow

By Andy Godley, senior consultant for Flow Measurement and Metering, WRc plc

While options for clean water flow measurement abound, there is room for improvement on the wastewater side — but new technologies are closing the gap.

Flow measurement underpins almost every aspect of the water and wastewater industries. In the clean water part of the cycle, flows are monitored and measured at all stages from source to delivery, driven by factors such as environmental protection (abstraction), reduced leakage, and revenue generation. On the wastewater side, however, there is generally less flow measurement in place as, historically, the drivers for wastewater flow metering have not been as strong.

Playing Catch-Up

There are significant technical difficulties when metering wastewater that make it much more challenging to measure than clean water and may also partly explain why there is less metering of wastewater flows.

Firstly, once abstracted, most clean water travels through pipes that are pressurized by pumping or gravity and run full. Wastewater, on the other hand, is often running through partially-filled pipes, sewers, and channels with a free surface flow. Closed-pipe flow is, on the whole, much easier to meter than open-channel flow, where the level of fluid and its velocity can vary independently. Thus, a given volumetric flow in a specific channel may be a shallow, fast-moving flow or a deep, slow-moving flow. Unless a control structure such as a weir or flume is in place, two measurements — velocity and liquid level — are often required to calculate volume.

Clean water flows also tend to be contained in round pipes. In wastewater, we find all kinds of interestingly-shaped sewers and channels. When no structure is in place, the shape needs to be characterized with respect to depth to calculate the wetted area (volumetric flow being wetted area multiplied by mean velocity).

Then, of course, clean water is, by definition, clean; wastewater isn’t. Wastewater can be highly variable in content, carrying heavily-fouling substances such as fats, oils, and greases (FOG), as well as light solids and heavy solids, such as grit and other debris.

Pressing For Measurement

In the U.K., regulations stemming from the Urban Wastewater Treatment Directive and the Water Framework Directive have changed the emphasis on wastewater flow measurement. It is set to change even further with the new pressures on water companies caused by the Outcome Delivery Incentives (ODIs) put in place as part of the latest industry price review. These include, for example, incentives to reduce the incidence of sewer flooding. The consequences of pollution spills from malfunctioning combined sewer overflows (CSOs) are now more severe, with higher fines being levied by the Environment Agency for such incidents. This is leading, in the words of David Tyler, Environment Strategy Manager at Southern Water, “towards a more resilient and adaptive sewer network, one which is inexorably underpinned by in-sewer flow monitoring.”

Finally, there is also the opening of the retail market for water and wastewater services in 2017 in England that will allow non-household customers to buy their wastewater services from any provider, not just their local water company. This should stimulate new ideas for service provision with better understanding of wastewater discharges, underpinned by flow measurement.

The majority of wastewater, whether from residential premises, industrial, or commercial sites, is discharged to the sewer network. A large industrial user will have a trade effluent meter (TEM) monitoring its discharges so that charges can be levied based on the Mogden formula, which combines flow, solids, and biochemical oxygen demand (BOD) to assess loading on the treatment process. The opening of the retail market for non-household water services in 2017 is stimulating new interest in this area. Those offering services based on more accurate flow measurement, and hence more accurate charges, are likely to develop additional services that can be provided using this data.

Applying Solutions

This may be an area where insertable sensors, such as the Nivus correlation pipe sensor, can be used to good effect. Such sensors can be installed in a live pipe without disruption, but more importantly, can be removed for cleaning, thus providing ongoing accuracy. Some are already in use for monitoring trade discharges to the environment from on-site treatment plants.

At sites without trade effluent meters, charges are based on the metered potable water supplied. Where waste flows to a combined sewer that also receives surface runoff, adjustments are made in the charging mechanism. An interesting development for sites without a specific TEM, therefore, is the wastewater meter offered by Dynamic Flow Technologies.

This uses microwave technology to measure the actual discharged waste flow. Models have currently been developed for typical drain flows in 4-inch (100 mm) and 6-inch (150 mm) pipes and will allow charging based directly on the quantity of foul discharge, rather than some assumed relationship with the water in and unmeasured adjustments for runoff. This technology is currently on trial with Wessex Water in the U.K. and could lead to new charging mechanisms for sites where clean water usage is relatively low but where there are large surface areas for rainwater runoff (for example, an out-of-town superstore where relatively little clean water is used in toilets and canteen facilities, but there are large roofs and parking areas).

In-sewer flow measurement is perhaps one of the most challenging flow applications in the water industry, due to the highly fouling nature of the fluid. However, it is also one of the most necessary for the reasons cited above. Non-contact sensors that are less prone to fouling are clearly desirable.

While sewage levels are monitored quite widely using non-contact methods, non-contact velocity measurement is also now available using products such as the Raven-Eye and the LaserFlow. Both user Doppler methods — the former based on radar and the latter on lasers. These afford the opportunity to better understand what is going on in a sewer and distinguish, for example, level increases due to blockages and genuine high-flow storm events, both of which might lead to flooding but require different responses.

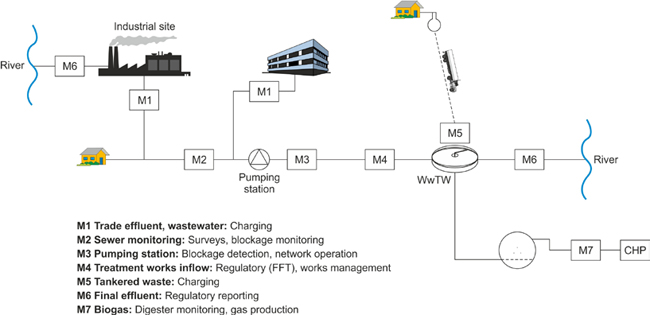

Measurement Points In The Wastewater Network

The Future In-Sewer

In-sewer flow measurement can also help manage loads going into treatment processes. WRc, an independent public limited company that provides water/wastewater research and consultancy, has recently been investigating the opportunity for smarter auto-desludging of primary settlement tanks. Desludging may be initiated by in-sewer meters warning of an incoming high load, thus creating headroom to deal with the first foul flush from a storm event and avoiding excess solids being carried through into second-stage treatment.

The Manning Formula (or derivatives) has long been used to estimate flow-rate based solely on a single level reading, though some of its assumptions and limitations mean that it is usually only an estimate at best. However, at the International Flow Measurement Conference held this July at Warwick University in Coventry, England, Laurent Solliec of Nivus presented an improved method using two-level sensors. This new approach can overcome some of the difficulties with traditional slope-area methods, such as coping with backwater. Tests in a sewer in Germany have been promising. Two-level sensors could provide a relatively easy-to-install and low-cost method for sewer flow monitoring.

The non-contact area-velocity meters are causing considerable interest for use on treatment works inflows and outflows, particularly now that independent testing by WRc under the Environment Agency’s Monitoring Certification Scheme (MCERTS) has shown such approaches as being capable of producing data of the quality required by the regulator. LaserFlow and Raven-Eye are opening up the market for such devices, but, like all innovations, their work raises new questions.

One key aspect that is being debated is the in situ calibration and verification of these devices. Under MCERTS, users are required to have ongoing confidence in the operation of their effluent flow meters, including measurement validation. Systems are also subjected to an external inspection and in situ verification every five years by an MCERTS inspector. There are a number of methods for doing this at the moment, but recent papers have identified new and potentially more convenient methods. Tamari, et al.1 report promising results from handheld radar, and Lüthi, et al.2 have developed an app for a mobile phone that captures the movement of the liquid surface using the device’s camera and analyses to give a measurement of flow.

Emerging, there are a large number of innovations for wastewater flow measurement driven by the need for better management of wastewater flows for environmental protection and the opportunities to develop new charging methods. It is often difficult to get new technologies accepted by a conservative water industry. There are encouraging signs that the U.K. water companies are becoming much more interested in implementing innovative solutions. Independent test schemes such as MCERTS and the European Environmental Technology Verification pilot project play a significant role in establishing the capabilities of new developments, though there is still work needed to develop methods for field verification.

References

1. S. Tamari, F. Garcia, J. Arciniega-Ambrocio, A. Porter, Testing a Handheld Radar to Measure Water Velocity at the Surface of Channels. Houille Blanche (3) p. 30-36, 2014.

2. B. Lüthi, T. Phillippe, S. Peña-Haro. Mobile Device App for Small Open Channel Flow Measurement. Proceedings. 7th International Congress on Environmental Monitoring and Software: Bold Visions for Environmental Monitoring, iEMS 2014 p. 283-287.

About The Author

Andy Godley is a senior consultant for Flow Measurement and Metering at WRc plc. Godley has been involved with flow for more than 25 years, working across both the clean and wastewater sides of the industry for users, suppliers, and regulators. He sits on a number of British, European, and international standards committees on flow topics.

Andy Godley is a senior consultant for Flow Measurement and Metering at WRc plc. Godley has been involved with flow for more than 25 years, working across both the clean and wastewater sides of the industry for users, suppliers, and regulators. He sits on a number of British, European, and international standards committees on flow topics.