Energy And Resource Recovery: Generating Resources, Not Waste Streams

By Aoife Moloney, water technology market analyst, BlueTech Research

“Sludge-to-energy” is trending in wastewater treatment, but what technologies have the most potential?

Increasing populations and urbanization are putting cumulative pressures on the Earth’s energy, water, and nutrient resources. As wastewater contains these valuable resources, it can potentially help address these issues. Several factors are driving energy and resource recovery, including tightening regulations related to the land application of sludge, sludge incineration, and sludge disposal at landfills, as well as rising sludge treatment and disposal costs. Given that sludge treatment and disposal can account for up to 50 percent of operational spending at a wastewater treatment plant (WWTP), a strong economic driver exists for finding efficient technologies and inexpensive, long-term disposal routes to reduce sludge management costs.

The increased emphasis on energy and resource recovery has become a primary focus for BlueTech Research, a market intelligence firm specializing in innovative water technologies. Areas of coverage, analyzed in a recent BlueTech Research Insight Report entitled Sludge to Energy – Biogas Generation and Utilization: Technology Trends and Market Potential, include biogas generation via anaerobic digestion (AD), biogas contaminants removal, biogas utilization via combined heat and power (CHP) technologies, and energy generation optimization practices such as pretreatment technologies and co-digestion. More efficient CHP technologies, sludge pretreatment, and co-digestion with high-energy fats, oil, and grease (FOG) can increase energy generation, reduce sludge volumes, reduce sludge management and operational costs, and provide a viable waste management solution for food wastes.

According to the most recent WEF Biogas Survey (2012), sewage sludge is anaerobically digested at approximately 1,238 WWTPs in the U.S., most of which are more than 1 MGD in capacity. Approximately 270 of these 1,238 facilities (22 percent) utilize the produced biogas through CHP, which equates to approximately 231 megawatt (MW). The remaining 968 plants (78 percent) use the biogas for digester heating and potentially space heating; the surplus is wasted or flared. Considering the pretreatment market in the U.S., in particular for the Cambi thermal hydrolysis pretreatment (THP) technology, there is potential to increase market share considerably in the plants with AD. Cambi has installed its first THP plant in the U.S. at the Blue Plains facility in Washington, D.C., with an installed capacity of 149,000 tons of dry solids (TDS)/year. If the initial focus were primarily on the 270 AD plants, which utilize their biogas in their CHP units, the total installed Cambi capacity would be approximately 1.7 million TDS/year (assuming a two-thirds uptake rate). This would represent an 11-fold increase in installed capacity within the U.S. market for Cambi.

BlueTech’s comprehensive analysis of “sludge-to-energy” technologies provides several key takeaways:

- Anaerobic Digestion Is The Principal Sludge-To-Energy Technology

The predominant sludge-to-energy technology on the market is AD, which has a dual purpose: It stabilizes the sludge and generates a biogas. AD is advantageous for use in WWTPs, as it is a well-established and robust sludge-stabilization technology. Also, AD does not require a dewatered sludge feedstock prior to digestion, unlike gasification or pyrolysis. This reduces the energy consumption and operation costs associated with dewatering.

- Internal Combustion Engines (ICE) Currently Dominate The CHP Market

Various energy-generation CHP technologies that were assessed include fuel cells, microturbines, ICE, and the Stirling engine. While ICE currently dominates the CHP market, underutilization of biogas at smaller WWTPs and tightening air regulations could alter this. Small-capacity (30kW-1MW), low-air-emissions microturbines offer an opportunity for the smaller WWTPs to start consuming their presently untapped biogas. Currently, these smaller plants do not utilize the biogas due to perceived and actual barriers, such as inadequate payback and economics. Noncombustion fuel cells, although still relatively expensive, offer the cleanest and most efficient CHP option. They should see increased growth in this market as air regulations tighten in the U.S. and worldwide.

- Biogas Utilization Via CHP Or Direct Gas Grid Injection Depends On A Number Of Factors

Decisions on whether the produced biogas should be utilized via CHP or direct gas grid injection should be made through a high-level financial analysis which takes into account the capital costs, time-value of money, and the generated annual revenue. Factors to be considered include fuel quality, local circumstances, energy costs, monetary incentives available, and the time-value of money. Naturally, high electricity costs favor CHP, and high gas prices make grid injection a viable option. In the U.S., electricity and gas prices are lower than in Europe.

- Sludge Pretreatment Technologies Are Key To Unlocking Additional Energy

Sludge pretreatment technologies break up the bacterial cell walls and release the cell’s contents, thus unlocking all the additional energy within the cells. Pretreatment technologies include thermal hydrolysis, ultrasonic, mechanical, chemical, and electroporation pretreatment methods. Depending on which technology is utilized, advantages of pretreatment include sludge sterilization, sludge volume reduction, and process improvements, such as enhanced sludge digestibility and dewaterability and improved biogas yields. Because of growing sludge disposal costs, increasing energy costs, and tightening regulations, it appears pretreatment can offer an effective and viable solution to these issues.

- Cambi’s Thermal Hydrolysis Process (THP) Is Dominating The Sludge Pretreatment Market

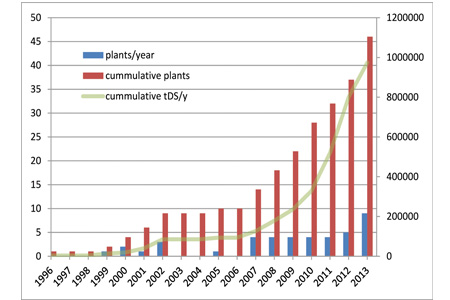

Each sludge pretreatment technology type has varying degrees of success and market infiltration. BlueTech concludes that the most dominant pretreatment technology currently appears to be Cambi’s THP process. This technology is very effective at essentially “pressure cooking” the sludge, which results in a breakdown of the cell walls and a release of the extra energy within the cells. The result is a more digestible sludge with higher biogas yields and decreased sludge volume, thus reducing sludge disposal costs. Cambi’s THP process also sterilizes the sludge to yield a Class A biosolid. Cambi’s THP technology is currently installed in 29 plants worldwide (total installed capacity: 787,740 total dissolved solids [TDS]/year), and is a good example of a disruptive technology making inroads into the mainstream market. Recent entries into the U.S., Spanish, and Swedish markets put Cambi in an ideal position to further grow and dominate this market. Opening the pretreatment market also paves the way for others to follow, such as OpenCEL focused pulse technology. Figure 1 shows Cambi’s growth worldwide since its foundation in 1996 to 2013.

Figure 1. Cambi thermal hydrolysis growth worldwide (Source: Provided by Cambi to BlueTech® Research)

- Co-Digestion Proves To Be Problematic In Practice

Co-digestion appears to be an exceptional prospect: a waste management solution for high-energy food waste and FOG combined with a synergistic benefit to the sewage sludge digestion process that results in increased energy production. However, co-digestion proves to be challenging in reality. Numerous barriers exist to its application in WWTPs. Lack of clarity about post-digestion disposal regulations, waste collection methods, de-packaging and pretreatment of the waste, and guaranteed digester capacity into the future are hindering co-digestion from becoming a standard practice in WWTPs.

Finally, although several barriers for biogas-to-energy exist, such as lack of capital investment, operational challenges, and technical issues (e.g. high energy use), none appear to be insurmountable. These barriers could be overcome with a combination of efforts. Detailed financial calculations could address and give confidence to prove the economic viability of such sludge-to-energy projects, and operational challenges and technical issues could be addressed with increased research and technological development.

In summary, a combination of efficient CHP technologies, pretreatment technology, and co-digestion can significantly improve the process operations of WWTPs through a combination of increasing energy generation and efficiency, enhancing overall sustainability, and reducing final sludge volumes and overall operational costs.

Aoife Moloney, water technology market analyst for BlueTech Research, has 10 years of experience in process control and optimization, auditing, and implementation of process improvements at wastewater treatment plants. Moloney recently completed a master’s degree in civil engineering (energy and environmental) at the Cork Institute of Technology.

Aoife Moloney, water technology market analyst for BlueTech Research, has 10 years of experience in process control and optimization, auditing, and implementation of process improvements at wastewater treatment plants. Moloney recently completed a master’s degree in civil engineering (energy and environmental) at the Cork Institute of Technology.