Eight2O Contracts ACWA Services For Low OPEX Nitrate Removal Plant

Thames Water through its alliance partnership Eight2O, has awarded a design and build contract to ACWA Services, a leading international water and wastewater solutions provider, for a new state-of-the-art Ion exchange Nitrate removal plant at the company’s Upper Swell water treatment works in Gloucestershire.

The solution, which offers improved operating efficiency and carbon savings, will replace an existing fixed bed solution which no longer meets Thames Water Asset Standards, partly due to serviceability issues and high OPEX costs for tankering large waste volumes for disposal off site.

Commenting on this latest Nitreat contract Peter Brewer, ACWA Services’ UK General Manager said: “This is our 3rd Nitreat project for Thames Water with others in operation at Sheafhouse and Wantage, and our 27th installation in the UK. The system has fast become the solution of choice for Nitrate removal offering a reliable, low cost, low carbon technology particularly suited to treatment works in sensitive areas, at the same time meeting demanding cost efficiency objectives and rigorous discharge limits. Low power consumption, reduced salt usage and low waste production are all key benefits for Thames Water.”

ACWA’s solution which covers design, supply, installation and commissioning for all process, mechanical, electrical and instrumentation works, is based on the company’s widely deployed Nitreat Ion Exchange process.

The design will provide capacity to treat a total raw water flow of 1.5 million litres per day, drawn from natural springs, reducing nitrate content from 70mg per litre to less than 5mg per litre. No blend arrangements are required as this is accomplished further downstream. The ten-month project is due for completion at the end of March 2017.

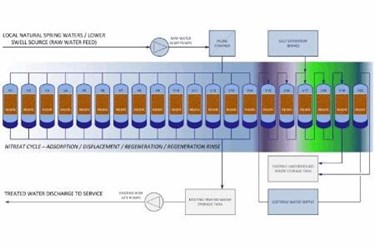

ACWA’s Nitreat system is a true counter current continuous ion exchange process, using a multiport valve for distributing feed and regenerating flows to multiple resin vessels. Proven in 26 installations across the UK, Upper Swell will bring this to 27, the solution offers a significantly smaller footprint than conventional processes and is able to cope with large variations in flow and nitrate levels.

Importantly for Thames Water, waste production is also a fraction of that of conventional plants, typically 0.5% of the works flow compared with up to 10% for some systems, which in turn will offer significant OPEX savings once the new plant is operational.

ACWA is responsible for the decommissioning, removal and disposal of the current treatment system from within an existing plant building at Upper Swell, along with the inspection and refurbishment of existing raw water pumps. A key challenge is to protect the fabric of the building during this process, ensuring that the new system fits into the existing space and the careful integration of control systems into the site wide SCADA system.

Components of the new system will include a self-backwashing strainer and manual bypass for the pumped raw water feed, with a 100% duty skid incorporating 20 resin vessels. Discharge from the plant will pass through a resin trap before entering service. Feed and discharge will be controlled by Nitrate monitors along with pressure and flow.

Subsidiary systems include a bulk salt saturator to provide brine for resin regeneration along with a duplex water softener system, storage and transfer systems. The small volumes of waste generated will discharge into an existing waste tank located below the main plant room for periodic collection and disposal.

With this latest project the total daily volume of UK drinking water now relying on ACWA nitrate removal is now in the region of 362 million litres per day. Other Water companies utilizing the technology are Anglian Water, Cambridge Water, Severn Trent and Yorkshire Water.

Abou ACWA Group

ACWA Group is a leading provider of innovative, sustainable process solutions for the air, water and wastewater sectors around the globe, providing design, build, operate and maintain capabilities.

The company’s wastewater expertise includes a portfolio of conventional and advanced technologies for wastewater and sludge treatment and wastewater reuse.

Solutions include some of the world’s most prestigious and challenging projects including the 64,000 m3/day Palm Jumeirah desalination development in Dubai and the flagship 76,000 m3/day Al Ansab MBR plant in Oman, as well as high profile projects for international clients including Kellogg’s, Coca-Cola Enterprises, Center Parcs and many major UK and International water service companies and government bodies. The company is also very active in the current AMP programme in the UK. For more information visit: www.acwa.co.uk.

Source: ACWA Group