Do Your Plant Instruments Play Nice With Others? The Benefits Of Integrated Technologies

The majority of monitoring devices found throughout a water treatment plant and distribution system — such as sensors for level, flow, and pH — are commonly analog 4-20mAdc. In other words, there is one output signal from the transmitter, so adjustments need to be made manually at its location. At the same time, putting the information produced by those devices into context and using it to improve performance through traditional data process management is labor-intensive.

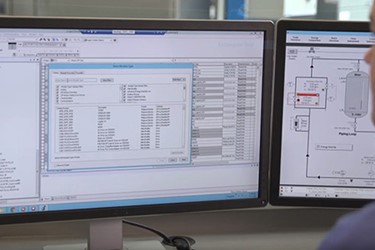

By comparison, digital signals provide two-way communication, so they can be programmed directly from the control room or with a laptop or handheld communicator. However, the bigger benefit is that they can be part of a system offering assured interoperability to provide a seamless flow of information. This type of integration between key components of the water treatment and distribution process improves overall decision-making and equipment optimization.

The benefits of integration can pay off over time. Coordinated engineering services that offer pretested and standards-based measurement, automation, and information solutions can significantly increase operational performance, quickly reduce errors, and vastly improve the maintenance process. They also make the instrumentation much simpler for the end user.

Water and wastewater treatment plant operators benefit from this digitalization because they can receive additional process information and achieve tighter control tolerances, so they can better manage their assets and improve their process.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.