Designing For Growth: How To Build Modular Capacity Without Breaking Ground Twice

The financial dilemma of sizing a new wastewater treatment plant—whether to over-build and waste capital on idle capacity or risk immediate retrofitting due to underestimation—is a common challenge. Traditional fixed-capacity systems often lock organizations into expensive rework cycles as communities and industries grow.

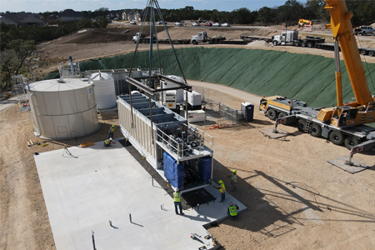

Modular design for Membrane Bioreactor (MBR) systems offers a strategic alternative. This approach requires first building the "skeleton" of the facility, such as electrical, blowers, and piping, to support the ultimate design flow. Standardized, skid-mounted MBR units are then phased in only as needed, matching capacity to actual demand. This allows utilities to triple flow with predictable installation and minimal downtime, eliminating the need to break ground twice and ensuring the infrastructure is built to evolve with changing flow rates, loads, and regulatory requirements. Learn how to structure your next project to embrace adaptability and growth.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.