Cost x Carbon x Energy: Passive Onsite vs. Centralized Wastewater Treatment Systems

By Jonathan Kaiser

A new study quantifies the difference between onsite wastewater treatment and centralized systems in terms of actual costs and those to the environment.

With rapid population growth worldwide, green building and development are becoming increasingly important. It is estimated that the world’s population is increasing at a rate of approximately 75 million people per year. This increase in population creates an increased demand for potable water, leading to amplified domestic wastewater production. The wastewater infrastructure supporting a population must change to accommodate the population shifts on a local level. And this frequently means the construction of new homes served by an onsite wastewater treatment system or expansion of the footprint and capacity of centralized wastewater treatment plants (WWTPs).

An analysis was performed to quantitively determine the cost for treatment, embodied carbon, and embodied energy associated with the O&M of centralized WWTPs and two types of passive onsite wastewater treatment systems. Embodied carbon refers to the total amount of greenhouse gas emissions produced throughout the entire lifecycle of a substance. This includes emissions from raw material extraction, manufacturing, production, and transportation. Embodied energy refers to the total amount of energy consumed during the lifecycle of a substance.

O&M data were collected from 17 centralized WWTPs across eight states. The average influent flows were broken down for this analysis into less than and greater than 2 MGD (7.5 million liters per day). The same analysis was performed for two different types of onsite wastewater treatment systems: gravity and pump. Pump systems represent both pump-to-gravity systems and pressurized systems. For both centralized and onsite wastewater treatment systems, averages were calculated for the unit treatment cost, embodied carbon (kg CO2), and embodied energy (MJ) per kilogram of biochemical oxygen demand (kg BOD), and total suspended solids (kg TSS) removed.

Treatment Cost

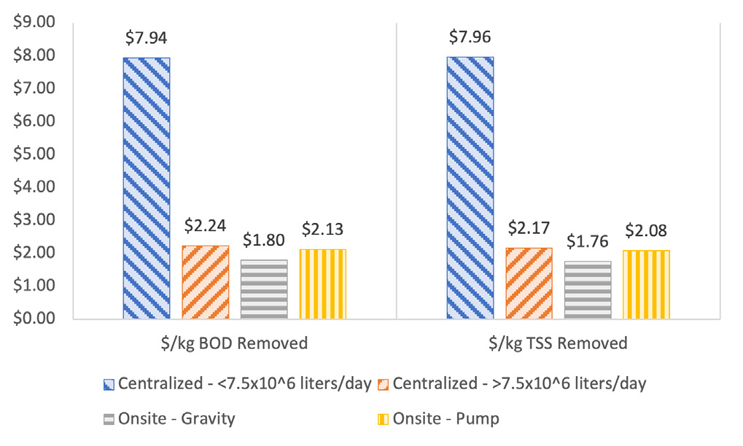

A summary of the total cost of BOD and TSS treatment for centralized and onsite wastewater treatment systems is shown in Figure 1. Compared to centralized WWTPs with daily design flows of less than 7.5 million liters per day, gravity and pump onsite systems achieve approximately a 78% and 74% cost reduction per kilogram of BOD and TSS, respectively. Centralized WWTPs with daily design flows greater than 7.5 million liters per day are shown to be much more efficient in treatment cost.

Figure 1. Average treatment cost for centralized and onsite wastewater treatment systems

Embodied Carbon Footprint

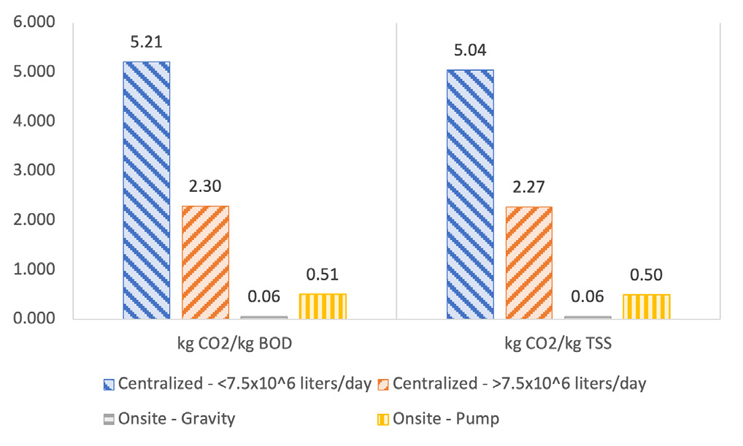

Figure 2 shows the embodied carbon footprint for centralized and onsite wastewater treatment systems. As shown, gravity and pump systems were calculated to only have a small fraction of the embodied carbon footprint as compared to centralized WWTPs.

Embodied Energy Footprint

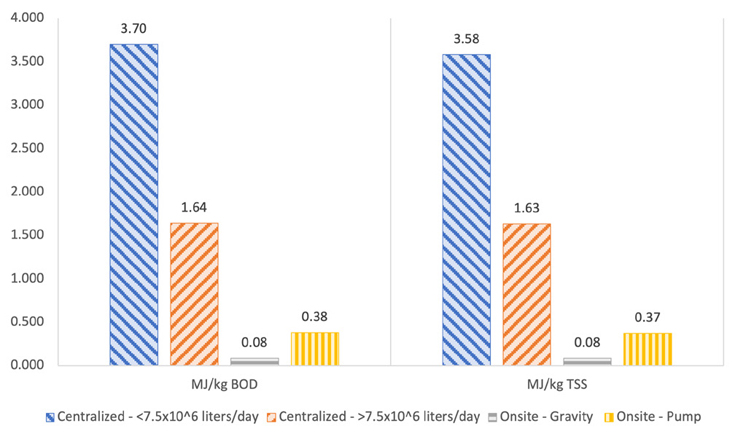

The average embodied energy footprint for centralized and onsite wastewater treatment systems is shown in Figure 3. Onsite wastewater treatment is shown to have a reduced embodied energy footprint from centralized treatment regardless of whether the centralized WWTP is above or below the daily design flow of 7.5 million liters per day.

onsite wastewater treatment systems is shown in Figure 3. Onsite wastewater treatment is shown to have a reduced embodied energy footprint from centralized treatment regardless of whether the centralized WWTP is above or below the daily design flow of 7.5 million liters per day.

Conclusion

As shown in Figures 1, 2, and 3, onsite gravity and pump systems provide a high reduction of treatment cost, embodied carbon, and embodied energy compared to centralized WWTPs. This applies to centralized WWTPs capable of handling both above and below 7.5 million liters (1,980,290 gallons) per day. Although both onsite and centralized wastewater treatment systems provide excellent treatment, there are substantial O&M cost savings relating to passive onsite wastewater treatment systems. The passive nature of soil-based treatment systems, where natural physical, chemical, and biological processes remove chemicals, viruses, and bacteria from wastewater is the biggest differentiator, as there is no cost to perform the treatment process itself. There is an incrementally higher treatment cost associated with pumped onsite wastewater treatment systems, but the costs are still substantially lower than WWTP treatment system costs. As with the cost of treatment, the lack of substantial energy input and the absence of chemical additions provide a greatly reduced embodied carbon footprint and embodied energy footprint associated with onsite wastewater treatment systems.

Other Considerations

Two prominent contaminant classes of emerging pollutants in wastewater are pharmaceutical and per- and polyfluoroalkyl substances (PFAS). Although pharmaceuticals and PFAS are not new contaminants in wastewater, they are of emerging concern due to their potentially detrimental environmental and public health implications.

When humans consume pharmaceuticals, their bodies partially metabolize the drugs. The rest is carried through to wastewater treatment systems. The presence of pharmaceuticals in wastewater systems raises potential environmental and public health concerns. At low concentrations, pharmaceuticals can still negatively affect the biology of aquatic ecosystems. The contribution of pharmaceuticals to the embodied carbon footprint and embodied energy footprint in wastewater is indirect. Pharmaceuticals can complicate treatment processes, especially for centralized WWTPs. Additional energy and resources may be required to effectively eliminate the presence of these compounds during the treatment processes. Also, during combined sewer overflow (CSO) events, when raw sewage is discharged from centralized WWTPs, the untreated pharmaceuticals enter receiving waterbodies and contaminate the environment.

Figure 2. Average embodied carbon footprint per kilogram of BOD and TSS removal for centralized and onsite wastewater treatment systems

Figure 3. Average embodied energy footprint per kilogram of BOD and TSS removal for centralized and onsite wastewater treatment systems

PFAS are human-made chemicals that are common in consumer products because of their beneficial water and grease-resistant properties. Research is ongoing relating to specific embodied carbon and energy values related to PFAS, but the production of PFAS is known to require an immense amount of energy. And treating wastewater contaminated with this pollutant can be challenging, often requiring the use of advanced wastewater treatment technologies. These technologies consume elevated amounts of energy, contributing to the overall energy footprint.

Both pharmaceuticals and PFAS create challenges for WWTPs. Typical treatment processes in these plants may not effectively remove these substances. PFAS, for example, are known for resistance to degradation. Mitigation of these emerging pollutants in wastewater requires increased energy, leading to increased treatment costs and increased carbon and energy footprints.

As society becomes increasingly aware of sustainable development, it’s important to incorporate lifecycle assessments into wastewater management and treatment processes to develop environmentally friendly solutions to address these emerging pollutants, while minimizing the overall environmental footprint of the wastewater treatment.

About The Author

Jonathan Kaiser joined Infiltrator Water Technologies (Infiltrator) in 2016 as a project engineer after graduating with his BS in environmental engineering from the University of Vermont. Jonathan spends his time at Infiltrator working on septic system design, product regulation, and R&D initiatives. He also serves as the vice chair of the National Onsite Wastewater Recycling Association (NOWRA) Emerging Professionals Committee and serves on the board of directors for the Connecticut Onsite Wastewater Recycling Association (COWRA).

Jonathan Kaiser joined Infiltrator Water Technologies (Infiltrator) in 2016 as a project engineer after graduating with his BS in environmental engineering from the University of Vermont. Jonathan spends his time at Infiltrator working on septic system design, product regulation, and R&D initiatives. He also serves as the vice chair of the National Onsite Wastewater Recycling Association (NOWRA) Emerging Professionals Committee and serves on the board of directors for the Connecticut Onsite Wastewater Recycling Association (COWRA).