Common Problems Of Ultrafiltration System Operations

By Nick Nicholas

One facet of technological advancement is attempting to mitigate the more glaring issues that consistently crop up due to the nature of a system process. Of course, even with decades of improvement nothing is infallible. In this article, we will discuss the common issues that can occur using UF filtration systems.

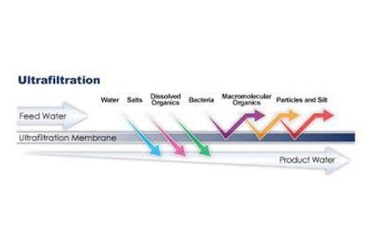

Ultrafiltration is a pressure driven membrane separation technology that is a compact and refined filtration method utilized in drinking water and tertiary wastewater reuse applications. Its semipermeable membrane can remove solids as small as 0.01 microns, including silt and viruses. However, membrane filtration technologies will have problems without proper care for appropriate pretreatment, operation, and maintenance.

UF filter systems are typically affected by three main issues:

Membrane Fouling

UF filtration, like any other membrane separation technology including reverse osmosis, is susceptible to what is known as membrane fouling. In simple terms, fouling is what happens when particulate matter adheres to the surface of a membrane. The unchecked buildup will eventually cause reduced efficiency, a pressure drop, and increased energy consumption.

There are a few different types of fouling that can occur. Each has its own cause as well as some differences in effects. Of these membrane foulants, some are reversible and others are irreversible.

Solids

Suspended solids and colloidal particles collect on the surface of the ultrafiltration membrane as well as within its pores, preventing the flow of water through the membrane. This fouling occurs more commonly in applications with high turbidity and suspended solids without appropriate pretreatment.

Scaling

Membrane scaling is not unlike what happens in pipes that carry water with high concentrations of hardness materials. When the concentration of these dissolved minerals is high enough to surpass the saturation limit of the solvent solution, they begin to precipitate out of solution onto the surface of the membrane. These minerals can crystalize, which makes them nearly impossible to remove without some sort of chemical cleaning or antiscalant pretreatment. Calcium and magnesium are two primary minerals that can cause scaling to occur on the UF filter system's membranes.

Microbiological

Biological contaminants like algae and microorganisms are often found in surface water sources. Provided with a warm environment and low flow rates, these contaminants will attach themselves to the surface of a membrane and begin multiplying. Over time, they can form a film that will prevent water from passing through the membrane and cause an increase in the trans membrane pressure differential. This increased pressure differential will put more strain on the pumps and increase the amount of energy they draw.

Waste Stream Disposal

This relates to the UF filter concentrate discharge. The filtration system did what it’s supposed to do and you have clean water that you can safely discharge into an outdoor stream without having to pay any environmental regulation fines. Or maybe you are going to reuse it somehow. Regardless of what is going to happen to it, you have this water resource.

However, what about all that contaminants that were removed? Sadly, this concentrate stream didn’t disappear into thin air, never to be dealt with again. Nope. It’s still there, whether it’s stuck to the membrane or sitting in a concentrate waste tank, and something needs to be done about it.

The problem is, you can’t just toss it out the window and call it a day. This reject wastewater is a concentrated form of whatever was in the feedwater. Therefore, in some cases, it may be safe enough to discharge into the environment; however, in others, the facility would be charged a hefty fine if it contains harmful pollutants.

Increased Permeate Contamination

This point is pretty rare for systems that are well maintained and monitored. To reiterate, permeate refers to the water that has been separated from the contaminating solids. It’s the clean water that you get out of this filtration process. Therefore, it’s definitely an issue when you start noticing that the quality of your permeate water is getting worse. Either there are larger solids or bacteria that should have been retained by the membrane contaminating the water.

This decrease in removal efficiency is usually indicative of a compromised membrane. Polymeric membranes can get worn out over time. High temperature or pH levels can degrade them pretty quickly, and without a decent pretreatment regime, rough particles can damage the inner pores of the membrane. To state the obvious, membranes do not work very well if they are full of additional holes (other than their pores of course). And now the system isn’t meeting it’s designed specifications and you have to replace the membrane and recirculate the contaminated permeate.