Combining Decentralized And Centralized Wastewater Treatment Strategies To Solve Community Challenges

By Dennis F. Hallahan, PE

To sustain the environment and smart community growth while protecting public health, engineers, municipal health officials, and regulators need innovative wastewater treatment solutions. The latest evolution of decentralized systems can efficiently handle residential and commercial daily flows and are a cost-effective alternative to the large, centralized wastewater treatment plants of the past. In fact, some decentralized community systems are collecting and treating more than 1 million gallons of wastewater per day. In many cases, a combined approach utilizing decentralized treatment strategies in concert with centralized wastewater districts or management structures offers the optimum solution for communities with minimum budgets for infrastructure projects and growing treatment needs.

The Intersection Of Centralized And Decentralized Wastewater Treatment

This combined approach could include expanding the wastewater district service area without extending the collection system out to new, distant parcels. The district can incorporate decentralized strategies by installing a satellite plant with subsurface disposal. Septic Tank Effluent Pumping (STEP) systems, where individual or groups of homes have tanks for wastewater that is collected and pumped to a centralized treatment facility, are an example of the intersection of decentralized and centralized approaches. Large commercial systems that have multiple wastewater-generating sources are also using a combination of technologies that could be traditionally considered on one or the other side of the centralized/decentralized fence.

Advanced Onsite Wastewater Treatment Systems (AOWTS)

Where individual onsite septic systems are the norm, town officials have a host of traditional and advanced decentralized treatment system possibilities to protect local waterways and water supplies, upgrade outdated systems to reduce nitrogen loading, and improve overall wastewater management for the community. Because of the advances in collection, treatment, and dispersal, decentralized systems previously only available for large-scale decentralized systems are now available for small-scale systems as well. The recent class of Alternative Onsite Wastewater Treatment Systems (AOWTS) offer high-level treatment strategies and system designs that address nitrogen reduction, watershed protection, and sensitive environments are particularly critical for coastal communities and those where dispersal to surface waters is no longer an option.

Many communities are utilizing a combination of approaches to solve their wastewater treatment challenges. These systems often provide collection that moves to a centralized treatment facility, then to a large disposal field. And most centrally managed decentralized wastewater treatment systems, such as publicly- and privately-owned community systems, are being staffed with trained and educated personnel in the same manner as centralized systems.

Finding less capital-extensive solutions that can extend the life and expand the capacity of existing centralized systems is also a high priority in many communities that have aging or undersized wastewater treatment plants but are open to smart sustainable development. AOWTS have been successfully installed to replace or rehabilitate outdated onsite systems such as cesspools and eliminate surface discharges. AOWTS are often paired with a range of updated components and new disposal field products such as plastic chambers, geosynthetic aggregate bundles, and large, plastic septic tanks. This increases the opportunity to protect natural resources and public health at a cost that communities can afford.

Engineers who are embracing these new options find them easily adaptable to various site conditions. Pre-engineered AOWTS provide long-term treatment solutions and professional management in many cases. What’s great is that they can be used in multiple small-scale or single larger-system applications.

Project Example: Subsurface Outfall for WWTP in Hopkinton, Massachusetts

The Town of Hopkinton had a municipal sewer system but did not have a wastewater treatment plant (WWTP). Their wastewater was being sent to other towns, but they were at their discharge limits. A study was conducted to investigate town-wide alternatives and to perform a cost analysis, which led to the construction of a new 350,000-GPD treatment plant.

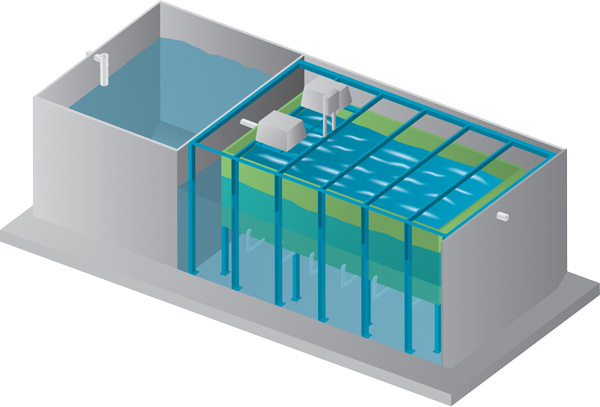

An innovative sewer-mining solution was designed that partially diverts flows from an existing sewer main to the new treatment plant. A new surface discharge was impossible, therefore a subsurface outfall consisting of a large infiltration basin was proposed. Due to the proximity to natural wetlands, the space available for the system was constrained. A highly efficient 80,223-square-foot Infiltrator chamber infiltration system solved this problem. Another challenge solved by the infiltration system was that it could fit on the constrained and irregular site, as well as recharge the local aquifer and adjoining wetlands.

Hopkinton installation

All homes connected to the community systems pay taxes and fees matching those paid by homes connected to the centralized system, which allows for sustainable operation and maintenance. One of the subdivisions serviced by decentralized wastewater treatment is the Elysian Heights wastewater treatment system. This system was designed to serve a 324-home subdivision and five acres of commercial land.

Advanced Treatment Units And Packaged Treatment Plants

Many packaged treatment systems have proven performance in not only obtaining exceptional secondary effluent quality, but also accomplishing nutrient removal and disinfection. Just about any treatment system technology available for large-scale plants is now available to develop small “plug and play” systems to meet even the most stringent effluent requirements. Activated sludge systems, trickling/media filters, integrated fixed activated sludge (IFAS), moving bed bioreactors (MBBRs), and even membrane bioreactors (MBRs) have been scaled down for use in some of the toughest applications. A range of applications — from schools with high incoming total nitrogen (TN), to restaurants with very high biochemical oxygen demand (BOD), to even direct discharge applications — can be addressed with decentralized packaged systems.

Project Example: ECOPOD-D from Delta Treatment Systems Solves Waste Treatment Challenges for Rural Alabama Town

The town of Section, AL, is in the northeast corner of the state and has a population of 770. This 30,000-GPD system was designed to treat the domestic waste produced by both residential and commercial entities. Phase 1 of the two-phase project is designed to treat 30,000 GPD domestic waste at a strength of 300 mg/L for both BOD and total suspended solids (TSS) and to handle an average daily flow fluctuation over a range of 50 to 100 percent. For optimum system operation, the ECOPOD units were completed and shipped directly to the site ready for installation, including all component equipment required.

The ECOPOD units were installed in poured-in-place concrete tanks equipped with aluminum hatches. A 14,200-gallon flow equalization tank was installed prior to the ECOPOD treatment reactor tanks to store the wastewater and evenly dose it to the ECOPOD treatment system throughout a 24-hour period. The flow equalization tank includes duplex pumps to ensure flow surges don’t reduce the efficiency of the treatment system. A 19,190-gallon primary tank precedes the flow equalization tank. The effluent also passes through a UV system for disinfection of fecal coliform to concentrations below permit levels. A drip disposal system, also supplied by Delta Treatment Systems, includes an effluent pump chamber, headworks, tubing, controls, and all necessary valves and fittings. A concrete building was erected onsite by the project contractor to house electrical controls and equipment.

Delta ECOPOD-D

The ECOPOD system requires minimal operation and maintenance once installed, although Delta does recommend hiring a qualified wastewater maintenance provider for commercial systems to ensure system components are working on a periodic basis. Weekly checks involve a visual inspection of operating equipment such as blowers and pumps to ensure they are working correctly. Monthly visits involve more hands-on maintenance, such as cleaning filters and refilling chlorine tablets (if needed). Semi-annual maintenance would be based on manufacturers recommendations for equipment, such as belt-tightening, UV bulb checks/replacements, or mechanical equipment lubrication.

Dispersal and Aquifer Recharge

One of the things that is diminishing is groundwater. There are sinkholes that are swallowing up land and homes, but even worse, large areas of land in the San Joaquin River Valley in California fell in recent years due to groundwater depletion. Using soil dispersal as part of the overall design of a decentralized wastewater collection/treatment/dispersal plan, groundwater is extracted, consumed, treated onsite, and returned close to its point of origin to recharge the aquifer. This is in sharp contrast to the centralized model, where treated wastewater is discharged to a river where it gets taken miles away from the origination point and is essentially a wasted resource. Because decentralized wastewater treatment systems return water to the aquifer, thereby replenishing groundwater supplies, they are preferred in coastal, arid, or conservation areas. In these situations, they provide exceptional treatment and preserve the sensitive environmental balance.

Project Example: Chambers Provide Reduced Carbon Footprint and Aquifer Recharge at California Biological Field Station

Blue Oak Ranch Reserve is a University of California-owned and operated biological field station and ecological reserve. A proposed renovation of the facilities, including new housing construction and a large utility infrastructure building, required the design of a wastewater treatment system to serve the expansion, protect the surrounding environment, and recharge the aquifer.

A wastewater recharge system accommodates the design flow of 3,280 GPD and includes 231 Infiltrator Quick4 Plus High Capacity Chambers in a shallow system installation. Wastewater is dispersed in two separate leachfields. The first leachfield serves the faculty residences and the student cabins and is a combination of gravity flow and pressurized (pump up) trenches. The second is a conventional gravity flow system. The two systems have septic tanks as primary treatment, with the soils providing final treatment and polishing of the effluent prior to it returning to the local aquifer.

The chambers were installed in trenches with minimal invasiveness and site disruption. The specification of recycled products for the wastewater system resulted in a reduced carbon footprint compared to labor-intensive mined aggregate, meeting the Research Station’s sustainability commitment. The decentralized wastewater treatment system design also met the goal of completing the water cycle and replenishing the local aquifer. With funding from the California Wildlife Conservation Board, the project exemplifies full-spectrum thinking to achieve water conservation, wastewater treatment, and energy sustainability goals.

Conclusion

Finding cost-effective, sustainable solutions for wastewater infrastructure challenges is a balancing act for communities and wastewater engineers. Local codes, proximity to water bodies, and anticipated daily flows are key factors for individual, commercial, or community systems. Technology continues working hard to keep pace with stringent regulations. Environmental demands have pushed the development of highly effective AOWTS. Treatment strategies that use the best of both decentralized and centralized strategies, often in concert, are proving successful and cost efficient for communities nationwide.

Dennis Hallahan (dhallahan@infiltratorwater.com) has over 30 years of experience with onsite wastewater treatment systems’ design and construction. Currently Technical Director at Infiltrator Water Technologies, he is responsible for technology transfer between Infiltrator and the regulatory and design communities and consults on product research and testing for universities and private consultants. Hallahan received his MS in civil engineering from the University of Connecticut and his BS in civil engineering from the University of Vermont. He is a registered professional engineer in Connecticut and holds several patents for onsite wastewater products.