Chemical Storage Tanks

Gregg Palmer, Director of Sales and Marketing for Poly Processing, discusses the design considerations and importance of resin structure in chemical storage tank construction.

The following is an excerpt from a Q&A with Water Online Radio. Click on the Radio Player above to hear the full interview.

Water Online Radio: What does Poly Processing do?

Gregg: We've been manufacturing chemical storage tanks for over 40 years. We have specialized in storing inorganic acids and bases that you're going to see in water-wastewater treatment.

We’ve tried to bring a lot of innovations, even though it's a static piece of equipment. You don't think much about a tank. It doesn't have moving parts and pieces, but the design elements that we've incorporated into our tanks really bring a different factor of safety, whether it's starting with the type of resins that we use or just the innovations that we've added to the tanks over the years. We try to be an industry leader and do it in a very safe and mindful manner to support operators.

We manufacture all of our tanks out of polyethylene, and a specific type of polyethylene, called crosslink polyethylene. That's a thermoset resin. Household items are typically made out of a linear polyethylene, or a thermal plastic. Crosslink polyethylene is designed specifically for critical applications. Thermoset means it is covalently bonded, so the molecular chains are locked together through the processing.

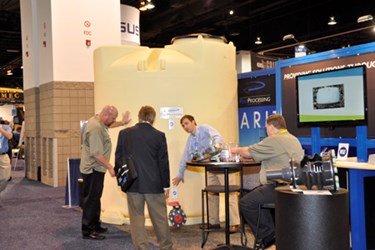

Water Online Radio: What tanks do you have featured here at ACE 13?

Gregg: Here at ACE, we brought our IMFO tank, or our Intricately Molded Flanged Outlet. It's a full-drain tank with an intricately molded flange so the bottom allows for a full drain. For an application such as a sodium hypochlorite situation, where you may build up transition metals in the bottom of the tank, it's going to facilitate the flushing of those, making the chemical more effective, and eliminating ancillary equipment damage.

Water Online Radio: Do you use the same materials to build all the tanks, or is it dependent on what's going to be stored in them?

Gregg: It can vary. The basis of all designs is going to be crosslink polyethylene, but for heavy oxidizers such as sodium hypochlorite, we’re going to use a special resin or a second resin about two-thirds of the way through the process. That allows us to increase the antioxidant properties of the resin, so that as the chemical breaks down or tries to attack the tank, it prevents that oxidation.

Water Online Radio: Talk about the design of the tanks. How are they engineered?

Gregg: We've developed our own resin to optimize the mechanical properties. Our standard is ASTM D1998. That defines the wall thickness per the chemical that we're storing and the overall mechanical properties that adds longevity to the tank...

Click on the Radio Player above to hear the full interview.