Building Tomorrow's Water Infrastructure: Insights From The Pacific Northwest's Largest Water Conveyance Program

By Erik Peters, Mike Warriner, and Scott Gibson

As water utilities across the country grapple with aging infrastructure, population growth, and increasing climate uncertainties, a major infrastructure initiative in the Pacific Northwest demonstrates effective approaches to meet these challenges. The Willamette Water Supply System (WWSS) — spearheaded by the WWSS Commission, a partnership of the Tualatin Valley Water District and the cities of Hillsboro and Beaverton, Oregon — is a $1.6 billion investment in resilient water infrastructure.

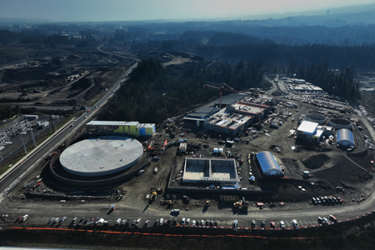

The Willamette Water Supply Program (WWSP) addresses multiple water system challenges through integrated planning and design. The system will deliver water from the Willamette River to the rapidly growing Tualatin Valley through a network of seismically resilient infrastructure. The system’s cornerstone is a state-of-the-art, 60-MGD water treatment facility, designed with expansion capabilities to 120 MGD. This scalability enables the facility to meet both current demands and future growth without significant retrofits.

In addition to the water treatment facility, the program encompasses 13 major projects, including:

- More than 30 miles of large-diameter pipelines (66-inch and 48-inch) built to modern seismic standards

- A modified intake on the Willamette River

- A 15-million-gallon terminal storage reservoir on Cooper Mountain

- Ancillary facilities designed to enhance system reliability

When complete, the WWSS will be one of the most seismically resilient water systems in Oregon, engineered to withstand natural disasters, protect public health, and speed regional economic recovery by restoring critical services following natural disasters faster than ever before.

Managing Construction Challenges

The project’s scale and complexity required sophisticated construction-management approaches. Carollo Engineers, in partnership with Stantec, provides both program-management and construction-management services, having secured the construction-management contract in 2017.

The construction-management scope includes oversight of the intake, treatment facilities, reservoirs, and large-diameter pipelines through a variety of jurisdictions. Some system components, including the reservoir and major pipeline segments, were constructed and tested up to three years before final system integration. Others, such as segments of pipe built to correspond with planned roadway construction — known as “opportunity projects” — were completed as much as eight years in advance. This phased approach allows for thorough testing and validation of each component while maintaining overall program momentum and limiting public disruption.

Community Buy-In

To mitigate community concerns about construction impacts such as traffic, noise, ground movement, and site access both during and after construction, program partners sponsored a coordinated public outreach program. A significant portion of the pipelines was originally routed through farmlands with no roadway access. By partnering with local government agencies such as Washington County, the Carollo/Stantec team modified the routing of some pipe reaches to parallel planned roadways to new developments. This significantly improved buy-in from local growers by minimizing impacts to their farms, while providing access during pipeline construction and for future maintenance.

A Focus On Local Participation

To boost the local economy, WWSP offered opportunities to as many local businesses as possible. Rather than hire a team of consultants and builders from outside the region, WWSP placed a high priority on giving those who live and work in the community the opportunity to contribute to this seminal project and share in its economic benefit. Efforts have included significant outreach to recruit local trades, contractors, and other businesses.

Bringing It All Together

Coordinating a major construction program so all components come together smoothly takes planning and skill. Key to success is implementing policies and procedures to streamline the construction process. For the WWSP, the strong emphasis on local business involvement resulted in participation of a larger than usual number of contractors. To keep costs in check, maintain a rigorous schedule, and avoid potential rework, the program employed specific contract language and a detailed construction-sequencing plan aimed at seamlessly transitioning the work from one contractor to another.

The commissioning process presented unique challenges, including testing a 15-million-gallon reservoir for leaks, connecting and flushing more than 30 miles of large-diameter pipe, and managing the associated water disposal. With construction completion now in sight, a comprehensive plan to address all interrelated program elements is more critical than ever. The commissioning team meets at least monthly to monitor construction and refine the plan to adjust to evolving issues.

“This joint effort between contractors, program staff, and operators from three different owners is all coming together just as planned, with the first water deliveries to customers scheduled for early 2026.”

—Tim Tekippe, Carollo Program commissioning and startup manager

Measuring Success

Despite the program’s complexity, it has evolved to adapt to shifting technical, regulatory, and economic issues over its 11-year duration, and work remains on track to meet the original 2026 completion date established in 2015. Plus, the overall program-change orders for the work currently stand at just 1%. This achievement is a testament to the discipline and technical acumen of the program participants. It reflects the soundness of the program objectives and the leadership of those dedicated to achieving them.

When complete, the system will provide exceptional finished water quality, improved water conservation measures, enhanced system safety, and greater source reliability and redundancy for the region’s growing population.

About The Authors

Erik Peters is Carollo Engineers’ director of construction management and operations. With more than 20 years of experience, he has overseen construction of more than $1 billion in water and wastewater facilities in the last five years, including the Willamette Water Supply System and large construction projects for San Diego, Nashville, and El Paso.

Erik Peters is Carollo Engineers’ director of construction management and operations. With more than 20 years of experience, he has overseen construction of more than $1 billion in water and wastewater facilities in the last five years, including the Willamette Water Supply System and large construction projects for San Diego, Nashville, and El Paso.

Mike Warriner, PE, CCM, is a senior vice president and a chief construction manager at Carollo, with experience in more than $2 billion in water and wastewater construction. As principal-in-charge for construction management of the Willamette Water Supply System, he offered lessons learned from working for project owners and construction contractors for more than 15 years prior to joining Carollo.

Mike Warriner, PE, CCM, is a senior vice president and a chief construction manager at Carollo, with experience in more than $2 billion in water and wastewater construction. As principal-in-charge for construction management of the Willamette Water Supply System, he offered lessons learned from working for project owners and construction contractors for more than 15 years prior to joining Carollo.

Scott Gibson, PE, is a vice president with Carollo, with 34 years of experience in the planning, design, and construction of water and wastewater projects. As design manager for the Willamette Water Supply Program, he is overseeing quality programs, design review, status reporting, plant operation, and change management.

Scott Gibson, PE, is a vice president with Carollo, with 34 years of experience in the planning, design, and construction of water and wastewater projects. As design manager for the Willamette Water Supply Program, he is overseeing quality programs, design review, status reporting, plant operation, and change management.