Bioleaching For Enhanced Sludge Dewaterability — Pilot Study And Full-Scale Application

By Weizhong Xiao, Yu Yuan, Juan Tao, and Sami Sarrouh

Innovation doesn’t always flip current thinking on its head; in many cases, it improves an existing process to give it better or wider application. Such is the case when bioleaching is applied to wastewater sludge.

For most municipal wastewater treatment facilities, the dewatering process is deemed as one of the most important steps toward achieving minimum sludge volume for the lowest possible handling cost. Hence, the intrinsic dewaterability of sludge — in particular, biological process sludge — is one of the key parameters in determining how effective and efficient the mechanical dewatering performance would be. Various technologies have been developed to improve sludge dewaterability, but most focus on chemical conditioning, such as fluctuating the types and dosages of various chemicals to alter the sludge physicochemical characteristics and help release the trapped water. Not much effort has been put into developing biological approaches to dewaterability, which, in most cases, could be more cost-effective.

This paper presents an innovative and promising biological sludge condition method — bioleaching, which has proven to be more effective than chemical conditioning. Bioleaching is a process originally used in the mining industry during the process to extract and recover the heavy metals from insoluble ores. The involved biological transformations are governed by bio-oxidation, mainly mediated by two groups of chemolithoautotrophic and extremely acidophilic (meaning organisms thriving at pH values as low as 2) bacteria, Acidithiobacillus ferrooxidans and Acidithiobacillus thiooxidans. Although the process has been used for decades, only recently was it noted that bioleaching can improve sludge dewaterability by at least a factor of 4-10 compared to the control test by solubilizing the extracellular polymeric substances (EPS) of the sludge that impede dewaterability the most.

The Ningbo Southern Wastewater Treatment Facility treats municipal wastewater with a conventional anaerobic-anoxicaerobic (A2O) bioprocess. The produced sludge was dewatered by centrifuge after chemical conditioning, resulting in total solids (TS) after dewatering of approximately 20 percent, though optimal protocols were applied. One approach implemented to improve dewaterability was to replace the centrifuge with a plate and frame filter press. After replacing, the dewaterability only improved from 20 percent TS up to 30 to 35 percent. To further increase the dewatering performance, employing an innovative technology became necessary.

When used for dewatering, one of the advantages of the bioleaching process is that the dewatered cake TS content can be as high as 40 to 45 percent under filter press without using chemical conditions, while chemically conditioned cake TS percentage is rarely higher than 30 percent. This resultant high-cake TS percentage is desperately needed under many circumstances.

By nature, the microorganisms responsible for bioleaching are chemolithotrophic because they utilize ferrous and reduced sulfur as their energy resources for growth. During biooxidation, reduced sulfur is converted to sulfate-releasing protons, causing the resultant pH to decrease to 3~4 or even lower. This bio-acidification is also hypothesized to be one of the reasons for improving the sludge dewaterability, in addition to other mechanisms. However, typical municipal sludge doesn’t contain significant amounts of reduced inorganics after the aeration processes. The anaerobic digested sludge does carry a certain amount of sulfide-related compounds and ferrous under some circumstances, but not an adequate amount to sustain and grow sufficient organism population to achieve dewatering improvement. In laboratories, researchers developed Medium 9K reagent to cultivate the involved organisms, but it is impractical for industries, especially for the wastewater treatment industry, to use Medium 9K reagent directly due to its prohibitive cost. Therefore, developing a relatively low-cost process to achieve a reasonable dewaterability improvement reagent for bioleaching becomes critical in order to use the bioleaching process in municipal sludge treatment.

Figure 1. Full-scale application for bioleaching process

Methodology

Both pilot and full-scale tests were conducted at Ningbo Southern Wastewater Treatment Facility (the Facility), Zhejiang, China, a typical A2O biological process treatment plant targeting both carbon and nutrient removal. All the raw sludge tested was gravity-thickened secondary sludge with TS percentage varying from 0.5 to 2.5 percent during the test period.

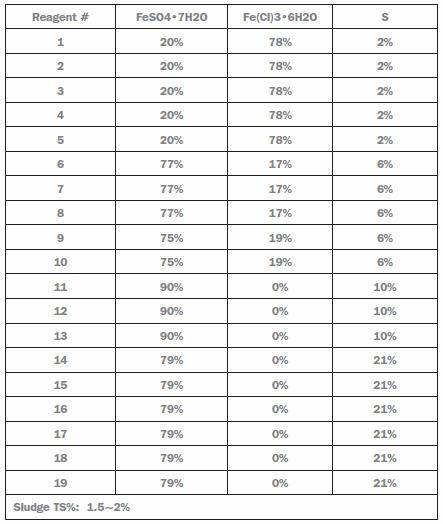

Table 1. Tested Reagent Major Composition (By Weight) And Sludge Condition

The pilot tests were carried out in six parallel-operated flat-bottom circular plastic reactors for a total of 19 different reagents. Medium 9K reagent was also used for control purposes. Each reactor has a volume of 5 liters (1.32 gallons). Aeration was provided by a coarse-bubble hose anchored at the reactor bottom. There was no precise control on the aeration intensity due to the limited site conditions. The reaction was designed as a batch operation with a total residence time of 48 hours. The tested sludge consisted of 1/3 seeding sludge obtained from a nearby incubation center, where two involved groups of microorganisms were inoculated with Medium 9K reagent, and 2/3 of the Facility’s secondary sludge from a fullscale gravity thickener. Two sludge streams were filled into the reactor simultaneously, and aeration was started immediately after. After 5 minutes, aeration of the tested reagent was spiked into the reactor and aeration continued for 48 hours. A 100-mL sludge sample was taken every 6 hours for a vacuum filtration test. It had been demonstrated in another study that the vacuum filtration time has a strong positive correlation with the final filter press cake TS percentage; therefore the filtration time was used to evaluate the dewaterability.

Figure 2. Dewatered cake through the plate and frame filter press after bioleaching

Tested reagent composition and the sludge characteristics are listed in Table 1.

Sample analyses included the sulfate, total iron, ferric, chloride, and pH, all measured with a Hach DR3900 spectrophotometer and Hach HQ11D portable pH/ORP meter (Loveland, CO), respectively. The filtration test was performed using a 47-mm fiberglass filter with nominal pore size of 1 micron (Pall Corporation, Cortland, NY).

Full-scale application was carried out in the facility’s existing 155,000-gallon concrete tank as shown in Figure 1. The tank was partitioned into 12 equal-size chambers, creating a plug-flow pattern. Fifty percent of the tank effluent was sent to the filter press without further chemical conditioning, and the other 50 percent of tank effluent was returned to the tank inlet, mixing with raw sludge for biomass retaining.

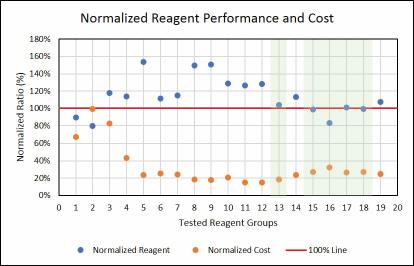

Figure 3. Normalized reagent performance (filtration time and cost) relative to the Medium 9K reagent (highlighted reagents were considered appropriate for full-scale test)

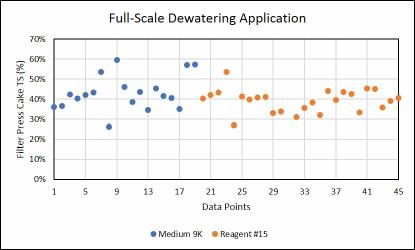

Figure 4. Full-scale filter press dewatering tests

Results And Discussion

The performance evaluation was done in two consecutive steps. The first step was to normalize the filtration time to that of the Medium 9K reagent control filtration time. Those normalized filtration times less than 100 percent, or not significantly higher than 100 percent, were screened out for next-step evaluation. The second step was to normalize the reagent chemical cost to the Medium 9K cost based on the amount of reagent used and their individual component unit prices. Figure 3 presents the pilot-testing results. The results indicated that Reagent #13 and #15~#18 were the ones that should be given attention from both evaluation criteria.

Reagent #15 was selected as the final reagent to use in the fullscale test. Figure 4 presents the full-scale performance for the one-month testing period. The results indicated that Reagent #15 had equivalent dewatering performance as Medium 9K reagent, but with only 30 percent of the cost of Medium 9K. The average cake TS percentage was approximately 40 percent. Further studies will be conducted to investigate how much more dewaterability the bioleaching process can achieve.

References

- Ömer Þimþek and Münevver Arýsoy, A New Approach for Evaluating Wastes: Bioleaching, Hacettepe Journal Of Biology And Chemistry, 2007, 35 (1), 17-24

- H.L. Ehrlich, Beginnings of rational bioleaching and highlights in the development of biohydrometallurgy: A brief history, The European Journal of Mineral Processing and Environmental Protection, 2004, 4 (2), 102-112

- Guy Mercier, Patrick Drogui, Jean-François Blais and Myriam Chartier, Pilot-Plant Study of Wastewater Sludge Decontamination Using a Ferrous Sulfate Bioleaching Process, Water Environment Research, 2006, 78(8), 872-879

About The Authors

Dr. Weizhong Xiao is a supervising engineer with T&M Associates. He earned his doctorate from the University of Central Florida. Since his graduation, he worked with the water and wastewater industry on process and design solutions for more than 15 years. In recent years, Dr. Xiao has been active in research and development, applying cutting-edge technology to engineering applications. Contact him at wxiao@tandmassociates.com or 216-952-2489.

Dr. Weizhong Xiao is a supervising engineer with T&M Associates. He earned his doctorate from the University of Central Florida. Since his graduation, he worked with the water and wastewater industry on process and design solutions for more than 15 years. In recent years, Dr. Xiao has been active in research and development, applying cutting-edge technology to engineering applications. Contact him at wxiao@tandmassociates.com or 216-952-2489.

Yu Yuan and Juan Tao work at the Ningbo Southern Wastewater Treatment Facility in Zhejiang, China.

Sami Sarrouh is with T&M Associates Inc. in Cleveland, OH.