At The Waterfront Of ESG And Environmental Responsibility

By Tomer Efrat

In today's competitive business landscape, where companies are expected to excel beyond just their bottom line, Environmental, social, and governance (ESG) assessments have become essential for organizational success.

ESG policy can yield a powerful outcome when integrated into a corporate strategy. Though strategizing and rolling out this assessment can be time- and resource-intensive, when done correctly, companies will realize several benefits in the short and long term, including:

- Better risk management, helping identify and mitigate risk, especially when it is connected to environmental and social issues.

- Increased investor interest, allowing companies to attract a broader range of investors, pulling in those who prioritize ethical and sustainable partnerships.

- Greater competitive advantage, giving organizations an edge in markets where sustainability is a key differentiator, standing out from less responsible players.

- Stronger financial performance, reducing waste and enhancing efficiency, helping companies become more profitable overall.

- Improved customer reputation, building an enhanced positive public image, supporting long-term customer loyalty and trust.

While many organizations are aware of such ESG-fueled benefits, achieving success in this arena isn’t always easy, with different challenges for different industries.

Water Industry ESG Compliance Challenges

Reaping the benefits of ESG initiatives starts with deeply understanding your industry and from there, building a sound strategy. In the world of water, where treating water is critical in driving the global water supply, and climate change is on the rise, there is an ongoing concern about the impact of desalination on the environment. Addressing the environmental criteria of ESG is especially important as desalination facilities are scrutinized for how they safeguard the environment and conserve its resources. Levels of energy consumption and carbon emissions are monitored amidst concerns about, ozone depletion, fossil resources, and chemical usage. Stakeholders and investors push to streamline desalination processes to reach minimal environmental impact and operational success in terms of CAPEX and OPEX.

Wherever desalination plants are located and operated, they should build their corporate ESG strategy, aligned with their facility's economic, social, and most importantly environmental goals. By aligning with ESG values and embracing sustainable desalination practices, companies can not only meet their water goals, but also contribute to a more sustainable, equitable, and prosperous future.

Marching Desalination Toward Sustainability

When done right, sustainability strategies have been proven to cut costs and improve operating profits. Yet, building a sustainability strategy to meet ESG desalination goals can be complicated, requiring in-depth research and thoughtful goal setting.

As 85% to 90% of a desalination plant's carbon footprint originates from its energy consumption, energy efficiency is one of the top ESG environmental challenges facilities face today, along with the source of energy used for the desalination process, which both significantly affect the plants carbon footprint. As the march toward sustainable desalination continues, plants are challenged to adopt the most advanced solutions and technologies to meet today's ESG environmental challenges and increasingly stringent regulations.

LCA — You Can’t Manage What You Can’t Measure

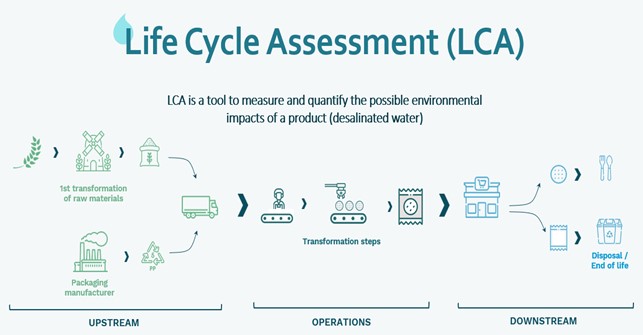

To effectively implement sustainable ESG metrics, we must be able to measure the environmental impact of desalination. Life Cycle Assessment (LCA) methodology provides comprehensive modeling of all desalination processes, input materials, resources, and outputs, enabling a measurable examination of each step along the plant's entire processes.

Using LCA methodology enables facilities to assess the desalination process, not only in terms of energy efficiency or product water cost but also concerning specific impact categories such as its carbon footprint (kgCO2/m3). By implementing the LCA framework, facilities can effectively measure and quantify their carbon footprint, directing their R&D efforts toward carbon-negative solutions such as ocean carbon dioxide removal (CDR) and green chemicals from seawater. This approach improves their OPEX toward minimizing emissions.

Achieving Sustainable Desalination

Achieving sustainable desalination to meet ESG goals requires the latest innovations and developments along with creative design strategies. Constant evaluation and analysis are needed to improve operations, quantifying energy amounts and costs to make way for greener energy sources, require state-of-the-art technologies including:

- Energy-efficiency performance and renewable energy sources: to reduce desalination plants' energy consumption and carbon footprint. Strategies for energy efficiency can be achieved by onsite power generation or power purchase agreements (PPA). Additional green energy solutions can combine solar energy and others within a facility's desalination profile.

- Direct-drive steam-operated RO plants: operating high-pressure pumps using steam with a direct connection to a steam turbine. The turbines can be fed from standard steam sources, heat recovery steam generators, or 'green steam' generated by biomass or biogas. When implemented and operated by a 'green steam' source, the direct drive approach can reduce the SWRO carbon footprint by up to 60%.

- Self-production of green-chemical: generating minerals from seawater/brine utilizing renewable energy can further result in significant economic and environmental advantages offering an eco-friendly alternative to traditional water and chemical sources. For example, in-house chemical production of CaO and CO2, simplifies the post-treatment process, maximizing the carbon capture potential and savings in chemical expenses. Another example is using an electro-chlorination system to generate sodium hypochlorite (NaClO) in-house, helping decrease the plant’s reliance on hypochlorite and significantly reducing energy costs.

- Carbon-negative solutions: the capture, storage and reuse of carbon in the desalination process help reduce a plant's carbon footprint and overall OPEX. For example, using an advanced onsite carbon capture utilization and storage (CCUS) system, CO2 emitted from a facility's power plant is captured, stored, and “recycled” back into the remineralization process ─ maximizing resources. With the sea as a primary source of chemicals, these innovations minimize the need for transportation and purchase of chemicals and can potentially power a fully sustainable desalination process (SDP).

- Pipe jacking: Pipe jacking is a well-proven method of installing pipes and conduits without trenches by applying a force that pushes the pipe through the ground while controlled excavation takes place. Using the pipe jacking method for laying out marine pipes, helps protect the environment surrounding the desalination plants and reduces carbon emissions.

- Smart membrane cleaning and preservation techniques: when implemented, they extend the lifetime of RO membranes by over 50% compared to the industry standards.

Promoting Change Today

Integrating ESG and sustainability metrics into corporate strategy is essential for organizations aiming for long-term success. In the water industry, forward-thinking companies adopt the latest innovations and evaluation tools that pave the way for achieving net-carbon-zero, self-sustainable desalination, setting new eco-conscious industry goals and standards. Incorporating advanced technologies that facilitate the transition to greener and more self-sustaining desalination is becoming a necessity to comply with external regulations and meet environmental safety demands.

ESG is now a guiding compass for businesses worldwide, pushing organizations to be more responsible and sustainable in all business practices. Those who fail to prioritize ESG will fall behind. Now is the time to make a change.

Leaders, what are you waiting for?

Tomer Efrat, Vice President of Research and Development for IDE Technologies, has substantial background and experience in the water industry, including seawater desalination as well as water and wastewater treatment. Tomer started his journey with IDE in 2005, first as a process engineer in the Thermal Process department and then serving in various technological and commercial roles, including Process Engineering Manager and Director of Business Development, leading IDE’s water treatment activity. He climbed up the ladder to his current position,VP of R&D, overseeing IDE’s work in this field while reinforcing IDE’s position as a global water technology leader. Tomer is an alumnus of Recanati Business School, Tel Aviv University, and he has an Executive MBA. He also holds a B.Sc. in Mechanical Engineering from Tel Aviv University.