Another successful HERO project treats cooling tower blowdown

This HERO technology was selected after careful consideration of the chemistry involved and the quality of water treated to economize the water usage in the cooling tower. According to the design selected cycles of concentration can reach 10 without harmful effects on the cooling towers. This application was considered the best economic approach. While the effluent from the HERO plant goes to the cooling towers as feed water, the reject, concentrated in silica is dumped into the brine disposal/drying pond.

Conventional RO system, running at near neutral or slightly acidic pH may be used with the addition of antiscalant with a limit on the concentration cycles because of the high hardness and silica content. Other options for zero liquid discharge include usage of brine concentrator/crystallizer with or without reverse osmosis system. These option are energy intensive though. The combination of the HERO reverse osmosis with the evaporation pond takes advantage of the small reject volume at high recovery rate (90% +) and the semi arid condition in the south-west USA project site.

The HERO system applied in this site is based on pretreating the cooling towers blowdown in steps including acidification followed by degassification to remove most of the alkalinity, then passing water into a solids contact clarifier where pH is increased using sodium carbonate. Other chemicals are also added to enhance the coagulation precipitation process. Hardness precipitates and is collected as sludge at the bottom of the clarifier, then is routed to the brine disposal/drying pond. The effluent form the clarifier passes through gravity filters then through weak acid cation exchangers (WACs) where hardness associated with alkalinity is removed substantially. Hardness to alkalinity ratio in the WAC influent is adjusted by caustic injection, thus insuring complete removal of the hardness. The wastewater emanating form the WACs during regeneration is collected and neutralized to an acceptable pH before dumping into the evaporation pond.

The HERO reverse osmosis elements run at high pH. Since hardness is removed there is no fear of mineral scaling. Advantages of running at this high pH include higher silica solubility, which permits higher recovery. Also silica ionization increase, which enhances silica rejection and thus produces purer permeate. This is reflected as operation at higher concentration cycles and more economic usage of water. In addition biological fouling is stopped as microorganisms are either killed or stopped from propagation at this high pH. This eliminates high pH cleaning is eliminated. Further acid cleaning is greatly reduced as the system runs at very low levels of hardness. The permeate streams from the HERO system is monitored for conductivity and recycled back into the cooling towers feed water tank. The recovery of the HERO system is at least 90%. This minimizes the blowdown of the cooling tower to a volume suitable for a reasonably sized evaporation pond thus achieving zero liquid discharge at the most economic cost.

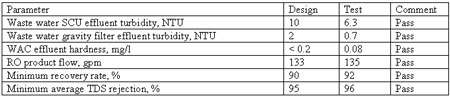

Following are design values compared to average values obtained during the performance test of the 300-gpm HERO system.

During this test the cooling tower blow down hardness was 450 to 550 ppm and had alkalinity 50 to 60 ppm as calcium carbonate. The HERO RO inlet silica was 40 to 50 ppm while it was less than 0.1 ppm in the permeate being concentrated in the reject to 400 to 500 ppm. Hardness in the permeate was less than 0.1 ppm.

Source: Aquatech International Corporation