Aerzen's Delta Hybrid Screw Blower: Features & Maintenance Considerations

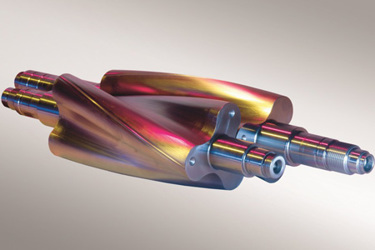

As energy costs rise, wastewater treatment plants are turning to more efficient aeration technologies like Aerzen’s Delta Hybrid screw blower. Combining the reliability of positive displacement blowers with the efficiency of screw compressors, the Delta Hybrid screw blower features a modified rotor profile that allows partial internal compression—delivering energy savings of 15% to 30% over traditional three-lobe designs. The result is smoother, vibration-free airflow, lower stress on piping systems, and superior performance for continuous, high-pressure applications. However, these benefits come with stricter maintenance requirements. The Delta Hybrid screw blower’s tight internal clearances mean that neglected bearing or oil maintenance can lead to catastrophic damage. Operators should begin detailed condition monitoring, including vibration and oil analysis, after four years of operation. Additionally, factory-installed sheaves cannot be field-replaced, emphasizing the need for proper service procedures. For plants seeking to balance efficiency with reliability, the Delta Hybrid screw blower offers substantial long-term savings—provided it receives the precision care its advanced design demands.

Get unlimited access to:

Enter your credentials below to log in. Not yet a member of Water Online? Subscribe today.