AEA Enhances CFX Computational Fluid Dynamics Tools for Reactors, Mixers

During the past five years, computational fluid dynamics (CFD) has fought for its place as an essential tool for chemical process engineers. The programs, which calculate fluid flow and heat transfer, have become much easier to use, and visualization tools have made the results simpler to interpret.

The latest stride forward comes from AEA Technology Engineering Software, a CFD leader and business unit of AEA Technology plc. (Didcot, UK). The company has upgraded its CFX-4 CFD software to improve handling of bubbles and voids and process chemistry. It also introduced CFX-ProMixus, an entry-level CFD program to optimize mixing vessel processes.

CFX-4

The new release of CFX-4 features two new physical models, MUSIG and PFDReaction, tools that enhance understanding of reactions in dispersions.

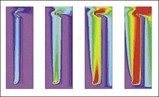

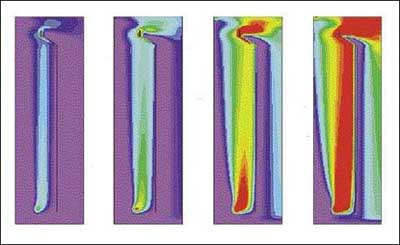

MUSIG. The new multiple size group (MUSIG) multiphase model simulates multiphase flows as it handles the behavior of multi-sized bubbles, including break-up and coalescence phenomena. The MUSIG model provides an accurate prediction of interfacial area, which is critical in such unit operations as gas lift reactors and contact tanks.

MUSIG was originally developed under the auspices of the European Commission-funded Advanced Design Methods for Improved Performance of Industrial Gas-Liquid Reactors (ADMIRE) project. AEA participated in ADMIRE's effort to adapt and validate CFD codes for gas-liquid reactors in the bubbly flow regime. The program generated new physical models for turbulence, interfacial reactions, bubble size distribution, packing, and chemical reactions.

PFDReaction. CFX-4's second major improvement is the use of PFDReaction to superimpose process chemistry on CFD calculations of fluid flow patterns.

AEA licensed the tool's code from Performance Fluid Dynamics Ltd. (PFD, Dublin, Ireland) in June 1999. At the time, AEA regional CFX manager Giles Barwell described PFDReaction as a "step change in the ability of CFD to model chemical reactions."

The program calculates chemical reaction rates in fluid systems. Several large chemical companies already use the code in conjunction with CFD software. PFDReaction is used to scale up processes, select reactors, and improve yield in polymerization, pharmaceutical precipitation, and competitive reactions. PFDReaction also has powerful combustion modeling capabilities, including NOx formation.

"Inclusion of reaction chemistry in CFD calculations will become commonplace in the next five years," said PFD managing director Joe Hannon in June. "Many companies invest separately in improving equipment design using CFD and quantifying the chemical reaction mechanisms in their processes: PFDReaction makes it possible to combine these data correctly and produce robust and efficient reactor designs, with shorter development cycles."

Under the licensing agreement, AEA Technology will markets and support its combined CFX-PFDReaction software, while PFD continues to own and develop PFDReaction and its interfaces to other software tools.

Other. CFX-4 also adds an effective means simulation of the complex physical phenomena that occur during explosions and deflagrations. Developed for the UK Health and Safety Executive, the new explosion model simulates the three stages of a deflagration: ignition; laminar, low-turbulence thin-flame growth; and the high- turbulence, thick-flame stage.

CFX-4 also offers specific tools for performance prediction of continuous casting of alloys such as steel, accounting for the transient and convective evolution of latent heat, and the resistive flow through the solidifying region.

CFX-ProMixus

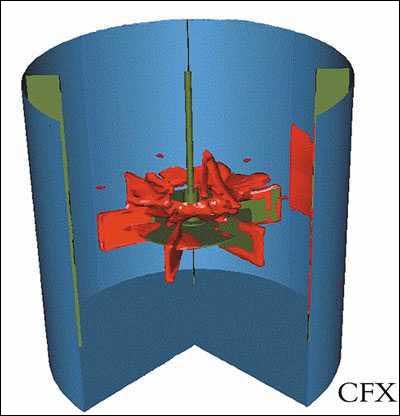

CFX-ProMixus is AEA Technology Engineering Software's new entry-level CFD software offering. The program has a simplified front-end user interface that allows people with little CFD knowledge to use CFD tools to analyze mixing vessel designs.

CFX-ProMixus has two modes. The express mode allows users to set up a mixing problem in a graphical interface. Users can pick from a series of standard reaction vessel, baffle, and impeller designs (or input their own). The program presents its analytical results as a gallery of graphics and tables that illustrate and quantify mixing performance. Results are accessible in a variety of digital formats, as e-mail, and over the Internet.

The system also provides an expert mode. This uses the CFX- ProMixus user interface as an input for the more sophisticated capabilities of CFX-4. This provides process and chemical engineers with CFD background a more in-depth understand reactor mixing issues. CFX-ProMixus also serves as a bridge between CFX's high- fidelity analysis and AEA's HYSYS process simulation and BaSYS batch process design applications.

In addition to HYSYS and BaSYS, AEA Technology Engineering Software markets software for separation process design (SPS), batch process design (BDK), heat transfer (HTFS), plant lifecycle data management (AXSYS), and fatigue and lifetime prediction solutions (nCode). The company has 20 offices worldwide, with subsidiaries in Canada, USA, Germany, Spain, France and Japan. It is part of AEA Technology plc, a 4500-employee technical services business spun off from UK's Atomic Energy Authority.

For more information: Glenn Smith, North American Marketing Manager, CFX, 554 Parkside Dr., Waterloo, ON, Canada N2L 5Z4. Phone: 519-886-8435. Fax: 519-886-7580.

By Alan S. Brown, Editor, Chemical Online, a sister site to Water Online within the VerticalNet family.