Advatech Introduces A Low-Cost Zero Liquid Discharge Technology For Power Plants

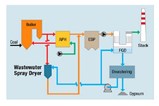

Advatech LLC, a joint venture between URS Corporation and Mitsubishi Heavy Industries America, has introduced the patented Wastewater Spray Dryer (WSD) as a highly economical means of achieving zero liquid discharge (ZLD) from wet flue gas desulfurization (FGD) processes at coal-fired power plants.

Advatech is a full-service EPC provider of advanced air pollution control and water management processes in North America. Its patented WSD technology offers a low-capital, low-operating cost alternative to traditional wastewater treatment technologies that eliminates any and all liquid discharge from the wet FGD process, and can even be used to treat other waste streams.

The WSD consists of a spray dryer installed in a small slipstream that bypasses the air heater. The differential pressure across the air heater provides the motive force for the flue gas, so in most cases a fan is not needed. The required liquid purge from the wet FGD process (in the form of filtrate) is added to the spray dryer through either dual-fluid nozzles or a rotary atomizer. The chlorides and other dissolved substances form solid particulate in the WSD that are removed from the flue gas along with the fly ash in the existing particulate control device.

The WSD is designed to maintain a conservative approach to saturation temperature, allowing for carbon steel materials to be used in construction without fear of corrosion. Since the unit is installed in a slipstream, it can be isolated at any time for inspection or maintenance without impacting boiler or wet FGD performance. The WSD does not have to run all the time and can easily handle swings in the dissolved solids content of the FGD purge stream, facilitating a return to the desired equilibrium chloride concentration after either a process outage or upset condition.

“The total installed cost of the new system is typically one tenth the cost of conventional treatment,” said Gregory Brown, General Manager for Advatech. “There is no chemical or biological treatment associated with the process, making it both easy and economical to operate. For a typical installation, the WSD process results in an approximate 3 percent increase in particulate loading at the cost of less than a 0.4 percent decrease to the normal heat rate.” For more information about the WSD process, visit: www.advatechllc.com.

About URS

URS Corporation is a leading provider of engineering, construction, and technical services for public agencies and private sector companies around the world. The Company offers a full range of program management; planning, design and engineering; systems engineering and technical assistance; construction and construction management; operations and maintenance; information technology; and decommissioning and closure services. URS provides services for power, infrastructure, industrial, oil and gas, and federal projects and programs. Headquartered in San Francisco, URS Corporation has more than 54,000 employees in a network of offices in nearly 50 countries For more information, visit www.urs.com.

About Mitsubishi Heavy Industries America

Mitsubishi Heavy Industries America (MHIA) is a subsidiary of Mitsubishi Heavy Industries, Ltd. (MHI), headquartered in Tokyo, Japan. MHI is one of the world's leading global heavy machinery manufacturers. MHI's diverse line-up of products and services encompasses shipbuilding, steel structures, power plants, chemical plants, steel plants, environmental equipment, machinery for industrial and general use, aircraft, space rocketry, and air-conditioning systems For more information, visit www.mhi.co.jp.

Source: URS Corporation