Addressing Global Drinking Water Challenges With IIoT And Automation Solutions

By Paul Bristow

Nearly a billion people worldwide lack basic water services and another billion lack safely managed drinking water, according to a United Nations Report on Water and Sanitation.[i] And the problem is only getting worse: Currently, 17 countries and 33 of the world’s cities[ii] with populations above three million are living under extreme water stress. That number is expected to rise to 45 by 2030.

Desalination is one solution that offers significant potential for addressing these problems and is receiving major investments in technology innovation. Unfortunately, at this point, desalination is one of the most expensive alternatives, requiring extensive mechanical, biological, and chemical treatments to create water fit for human consumption or even industrial/commercial use. The global desalination market is expected to reach a 7.8% combined annual growth rate (CAGR)[iii] through 2025 and provide 1% of the water we use, relying mainly on proven approaches, like reverse osmosis (RO) electrodialysis and multi-effect distillation (MED).

In addition to extensive water conservation efforts, which are the least expensive option, there are two cutting-edge alternatives looming on the horizon as possible ways to address the problem.

- Temperature swing solvent extraction (TSSE), which uses a solvent to extract freshwater more efficiently than other methods and at a fraction of the cost

- Battery electrode deionization (BDI), in which electrodes are used to remove salt ions from the water

Both are still in the research stage and have yet to be scaled up to industrial levels. It is yet to be determined whether they can continue offering economic and environmental benefits when scaled up to the level needed for large-scale commercialization.

As a result, traditional desalination efforts remain the most commercially viable alternative to deal with this global water challenge. Fortunately, advances in a wide range of technologies applied to other manufacturing and process systems may improve the ability of current desalination technologies to meet the need.

Greater Automation And IIoT Connectivity

Perhaps the key advance is enabled through the introduction of field devices with greater integration of sensors that allows for data collection and parameters not previously measured but now offered by the Industrial Internet of Things (IIoT). This enables greater levels of resolution and monitoring of assets.

Admittedly, many of today’s older plants were designed primarily for manual and semiautomatic operation. However, several factors, including the requirement to increase output, quality, and efficiency, are driving desalination plants to increase their level of automation and IIoT connectivity. Plus, as new IIoT-enabled equipment is added, plant operators will increasingly be able to capture real-time data from sensors, measuring pressure, temperature, level, flow, analytics (like pH) and wireless performance, while at the same time utilizing more precise control over these process parameters.

These new measurements will enable plant operators to monitor equipment remotely, improve plant performance, and quickly identify opportunities for predictive maintenance. Those capabilities provide a variety of benefits, including improved water quality, greater reliability, reduced downtime, and increased energy efficiency.

Improved Water Quality

Using sensors deployed throughout the plant, facility operators will be able to monitor critical performance information, like conductivity, chlorine content, dissolved oxygen, turbidity, and particle index in real time.

IIoT-enabled systems also include the ability to distribute key measurements to the appropriate managers in a plant. In fact, performance dashboards can be customized for individual job responsibilities.

Real-Time Actionable Data

The vision for IIoT-enabled systems — the critical value they offer — is actionable, real-time data that plant operators can apply to make incremental improvements on specific systems, as well as guiding more long-term decisions, such as investments in new technologies or implementing more effective programs to improve energy efficiency, thus eliminating waste or enhancing predictive maintenance efforts.

As a result, automation solution providers have developed “edge-computing gateways” that aggregate, analyze, and report key performance metrics from multiple devices. These gateways make it easier to implement IIoT solutions that utilize real-time equipment data, gathering and storing it either remotely or on cloud-computing resources.

Edge-computing gateways can reduce the burden on machine resources by operating independently from the existing control architecture while improving the accessibility of data; they can also reduce the need for high-capacity cloud servers and high-volume data transfer systems. Edge gateways also make the machine performance data more actionable because that data is collected and analyzed at the plant operations level.

A product like the Emerson RXi2 Edge Gateway allows analysis independent of the controller via local data collection and preinstalled analysis modules. It can monitor multiple points of analog or discrete inputs and outputs, connecting to all popular Fieldbus protocols.

The gateways can provide users with real-time, actionable information on the functionality of equipment, state of actuator wear, valves, and other devices, as well as the energy efficiency of pneumatic systems — without involving the existing machine controller.

Their programmable analytical capability can detect in advance when a machine or device’s critical limits are reached and provide users with the opportunity for early intervention — without loss of production time.

A plant operator might not be able to use an edge gateway for an entire plant but could certainly deploy several gateways to monitor critical operations in various locations throughout a plant.

In doing so, plant operators could have new information resources to help control a range of plant costs — such as energy consumption. Improving energy efficiency in desalination systems is critical to improving their value. The most common form of desalination, called saltwater reverse osmosis (SWRO), consumes an average of 10 to 13 kilowatt-hours (kWh) per every thousand gallons.[iv] Any place within a plant where wasted energy can be detected and fixed contributes to bringing that cost down.

Implementing the right sensors and tying their outputs into edge gateways, such as the Emerson RXi2, can help meet that goal. For example, the AVENTICS™ Series AF2 sensors monitor air consumption in pneumatic systems, enabling rapid intervention in the event of leakage. This helps optimize energy consumption, reduce machine downtime and cut costs, as well as providing critical data to edge gateways.

More Precise Control

Control valves are key to efficient operation in water treatment process applications. The ability to precisely monitor and control the flow within the system is critical to increase water quality, meet regulations, and streamline maintenance while reducing waste and cost.

Smart Valve Positioners, like those offered by manufacturers such as Emerson’s TopWorx and Fisher brands, provide a cost-effective and accurate solution for valve positioning and offer advanced diagnostic capabilities using industry standard communication protocols such as HART®. By accurately monitoring and controlling the valve position anywhere between its fully open to its fully closed position, smart valve positioners offer many useful features like auto calibration, simple operation, and integrated displays. These easy-to-use features, combined with their advanced diagnostic capabilities, significantly impact water and wastewater process control in a precise and cost-effective package.

Greater Reliability

Data from the sensors on critical pieces of equipment can be compiled and analyzed, enabling predictive maintenance warnings or alerts when important parameters are reached. For instance, a plant operator could receive an alert that a three-way solenoid valve, which pilots a pneumatically operated spring return ball valve, has reached 75% of the maximum lifecycle count. The alert would suggest that the solenoid must be replaced with a new unit before it finishes the rest of the cycles. This is achieved by adding proximity sensors on the pneumatics actuator, which counts the number of times the valve has opened and closed.

Reduced Downtime

By tracking the normal wear and tear on industrial equipment, as illustrated in the reliability section above, plant operators can take advantage of IIoT’s preventative maintenance capabilities.

They can schedule maintenance, repair, or upgrades of aging equipment during regular shutdowns before a problem occurs, thus avoiding costly downtime.

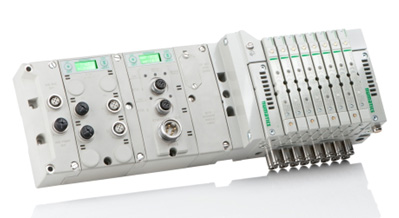

In addition, they can also deploy Fieldbus electronics with integrated displays that allow for easy commissioning without needing an external laptop, monitor visual status, and track input-output issues directly on the display.

Emerson’s Numatics G3 Fieldbus Communications node is an innovative graphic display used for easy commissioning, visual status, configuration, and diagnostics.

Increased Energy Efficiency

Air leaks can cause energy loss in mechanical systems. Plus, it can sometimes be difficult to identify the cause or the source of the leak. By monitoring the pressure and flow of these systems, plant operators can track their energy usage and identify potential problems before they occur.

Other new technologies include next-generation solenoid valves, which deliver lower operating costs, better performance, and greater reliability. They use advanced electronics to manage power, incorporating a power management circuit offering lower power consumption, enhanced pressure, and flow ratings. They can also add electrical surge suppression to both the solenoid and electronic controls.

Lead-Free Compliance

To enforce the Safe Drinking Water Act (SDWA), the U.S. EPA reduced the percentage of lead allowed in components of potable water systems, especially in solenoid valves.

The standards lower the permitted lead content from 8% to 0.25%. The brass traditionally used in solenoid valves contains 2.5% lead, so manufacturers have developed several standards compliant alternatives, including lead-free brass, stainless steel, and composite. These valves are designed to be drop-in replacements for existing lead valves.

Corrosion Resistance

Powerful pumps are required to push the seawater through the membranes that remove sediment and impurities. However, seawater or brackish water has an extremely corrosive impact on channels, equipment, and instruments as it goes through the desalination process.

Several technologies are now available to help address these issues. For example, new composite valves have been developed to combat the corrosive impact of seawater. To protect sensitive electronics and other production equipment, Emerson offers a range of hardened, integrated enclosures. Enclosures can be fabricated from a range of materials, depending on the level of protection needed, including stainless steel, iodized aluminum, composite, or any other specified materials, protecting internal systems from the external aggressive environment.

Water, Water Everywhere…

Addressing the world’s growing shortage of water will require a concerted effort of conservation together with a robust deployment of desalination technology. Technology advances, especially automation and IIoT connectivity, hold great promise for improving the quality, quantity, efficiency, and earth-friendliness of desalination efforts.

Paul Bristow is Product Marketing Manager, Water & Wastewater for Emerson (www.emerson.com).

References

i United Nations Report on Water and Sanitation, “SDG 6 Synthesis Report 2018 on Water and Sanitation,” 2018.

ii The New York Times, “A Quarter of Humanity Faces Looming Water Crises” 08/06/19.

iii Water Technology Online, “Growth expected for global water desalination market from 2018 to 2025,” 01/18/19.

iv Energy Central, “Desalination and energy consumption,” 01/20/2017.