Achieving Reliable Ammonia Removal In Lagoon-Based Treatment Systems

For most small to midsize lagoon-based wastewater operations, maintaining effluent quality throughout the year is a challenge. Much of this is fueled by the difficulty of meeting permit limits for ammonia discharge, especially during winter months when the temperatures are colder.

As a result, lagoon managers would benefit significantly from more reliability in the ammonia removal process.

A newer option to achieve this goal is the Parkson IGNITE™ process, which provides integrated nitrification in lagoon-based treatment systems by combining Parkson’s Biofuser® lagoon aeration system with Parkson’s TumbleOx™ nitrification reactor, a new non-activated sludge solution.

The IGNITE offering — which is simple to design, install, and operate — provides an alternative to achieve low biochemical oxygen demand (BOD), total suspended solids (TSS), and ammonia limits from existing lagoons without converting to an activated sludge process. This is ideal for municipalities with limited funding available for capital investments.

Behind The Technology

While there are processes similar to IGNITE that add aeration to lagoons and introduce a nitrification reactor of some form, they aren’t comparable to the Parkson solution.

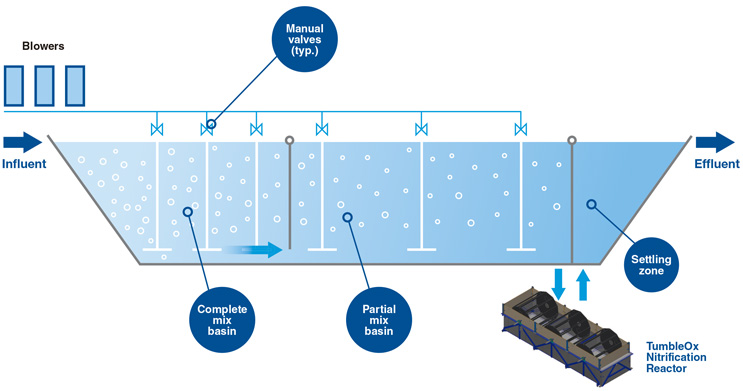

The Biofuser aeration system for lagoons consists of floating aeration chains that suspend fine-bubble diffusers near the basin bottom. Low-pressure blowers provide the air to all aeration chains with each chain isolated by a manual valve to allow for easy service and maintenance. The aeration system is designed to be completely suspended above the basin bottom with no supports or points of attachment, which allows for ease of access for service and maintenance without dewatering the basin or having a complete aeration system shutdown.

TumbleOx is a reactor that consists of a partially submerged rotating drum filled with media. The unique media design maximizes surface area for high concentrations of bacteria to form and provides aeration as the media moves in and out of submergence during drum rotation. It features low energy consumption, with each drum powered by a 1-hp drive unit, while maintenance is limited to bearing lubrication. Drum speed is set at start-up and there are no PLC controls or instrumentation to manage, keeping things simple for the operators, who often have a wide variety of responsibilities.

Courtesy of Parkson

The IGNITE process flow includes:

- A completely mixed primary aeration cell that provides significant influent BOD reduction using a relatively small cell volume (typically four- to eight-day hydraulic retention time);

- A partially mixed secondary aeration cell with sufficient volume to remove remaining BOD from the wastewater and convert some ammonia to nitrate; and

- The TumbleOx reactor, which removes the remaining ammonia in the secondary cell effluent using an attached-growth biological process. Excellent aeration and biofilm control provide reliable ammonia removal with discharge concentrations typically <1.0 mg/L. The attached-growth process has a low biosolids production with effluent TSS typically <30 mg/L, so effluent can be disinfected and discharged or sent to a settling zone for further solids removal, depending on permit requirements.

The IGNITE process flow. Courtesy of Parkson

Multiple drum configurations of the TumbleOx are available and can be designed for installation in owner-supplied tanks, either steel or concrete, or as prepackaged units built at the factory.

Installation Without Interrupting Operations

IGNITE allows small and medium plants to reuse existing lagoon basins because they can be segmented into zones with the Biofusers and TumbleOx reactors added while the operation remains in service. This is a practical way to upgrade a lagoon without converting to a full-blown activated sludge process that requires a separate clarifier and return sludge piping.

TumbleOx is a form of MBBR, a moving bed biofilm reactor, where the media are used as a surface to grow bacteria and aerate the water. This is a unique combination that negates having to install a separate blower with an aeration grid.

The IGNITE package offers municipal wastewater managers a solution for upgrading lagoons to meet tighter effluent quality standards at lower capital and operating costs while being much less complex to operate. Parkson also provides a process performance guarantee for IGNITE — that it will meet whatever permit levels are applicable for the system.