A Practical Approach To Using IoT Devices To Support Legacy SCADA Field Systems In The Transition To Internet-Based Industrial Automation Systems

By Steve Bullard

In the world of industrial automation, the talk is centered around “industrial internet of things” (IIoT). With buzzwords like “Industry 4.0”, “IoT”, “digital twin”, “cloud computing”, “artificial intelligence”, “machine learning”, and “deep learning”, it is difficult for automation engineers and business managers to determine how to implement these new technologies. The purpose of this article is to define a practical approach to using “internet of things” (IoT) devices to connect and support legacy SCADA systems in the transition to IIoT. The focus will be on remote, field automation systems, where there are additional challenges of communications, power, security, and isolation. These systems are deployed throughout the world in the electrical utilities, telecommunications, upstream and midstream oil and gas, and water utilities industries.

Background

Supervisory control and data acquisition (SCADA) systems have been around more than 50 years. They have evolved to be very effective for the job that they were designed: monitoring, controlling, and acquiring data from industrial equipment. The brains of a SCADA system are the remote terminal unit (RTU) and the programmable logic controller (PLC). These microcomputers are typically hardwired to sensors, actuators, and switches that use simple logic to control an industrial process. SCADA systems are limited in computing power and are not capable of artificial intelligence, therefore they are considered “dumb” systems. A human machine interface (HMI) provides information to the people responsible for managing the system. These systems communicate using their own languages, mostly proprietary, such as Modbus, DNP3, Profibus, and Conitel. Data from the components of the system are typically logged and stored on the system. These systems are typically a closed-loop system, controlled at a local level, and many times customized for the industrial processes that it controls.

On the other hand, information technology (IT) systems have evolved on a separate path, beginning with mainframe computers over 50 years ago to today’s client/server/router-based systems. The interconnectivity of these systems is what we refer to as the “internet”. The internet uses a standard communication language called Transmission Control Protocol/Internet Protocol (TCP/IP). All relevant business software, websites, email, databases, etc. run on these platforms. Because of the widespread use, IT systems have evolved at an exponential rate and now include “cloud computing” systems where multiple computing devices work together to increase computing speed and power. Breakthroughs in artificial intelligence (AI) allow systems to learn by computing enormous amounts of data, identifying trends, and creating conclusions.

IoT evolved when devices outside of computers were able to connect and interact on the internet. Smart phones are probably the most common IoT device. Over the last 10 years, other devices such as surveillance cameras, doorbells, swimming pool controls, building thermostats, and alarm systems all have become internet devices. IIoT refers to IoT devices designed to gather data and control industrial processes.

SCADA and IT systems are a common part of our everyday lives and control our world. SCADA systems control our manufacturing and infrastructure, such as utilities, traffic lights, factories, pipelines, dams, etc. IT systems run the internet, financial systems, business systems, communications, personal computing, etc.

The Problem For Businesses

Industry 4.0 refers to the “4th industrial revolution” where human, industrial, manufacturing, and infrastructure systems are integrated and monitored by internet devices. By using the internet to connect these systems, businesses can collect data, analyze data, monitor, and control processes from anywhere. Using cloud computing and AI, data scientists can analyze trends of processes and help businesses make more informed decisions with regards to efficiency, safety, maintenance, and other key factors affecting their bottom line. Also, interconnectivity of complex systems allow multiple different areas of a business to work together to achieve efficiency. For example, supply chain, manufacturing, transportation, billing, accounting systems all communicating on the same platforms increases efficiencies in processes.

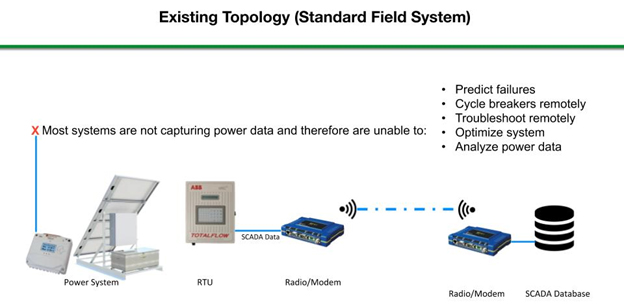

If Industry 4.0 is the goal, how do businesses transition from SCADA platforms to internet-based systems? Because SCADA systems control so many critical infrastructure systems, outright replacement is not feasible nor economical. SCADA systems speak a different language from IT systems and therefore can’t communicate with each other. Due to the fact that SCADA systems have always been closed systems, there are no security protections such as firewalls, encryption, etc. to protect against cyber-attacks. For these two reasons, integrating SCADA systems directly to the internet is also not feasible.

The Solution

As said earlier, this article will focus on remote systems where communication and power are sometimes issues with field automation systems, such as electrical transmission, pipelines, oil and gas well-sites, flood control, irrigation canal systems, water utilities, and mining operations.

Each situation is unique and must be assessed individually. In many cases, companies merge or are acquired and there may be SCADA systems of different types in the field, causing an integration mess. There is not a single best solution for all problems, but this is an overall strategy to move forward with integration.

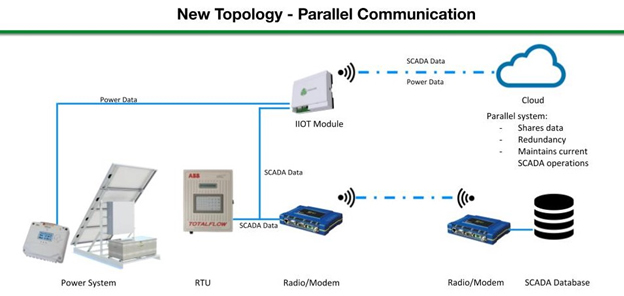

Step 1: Build an IIoT-based network of devices that collect critical data from SCADA systems. These IIoT systems do not interfere or control the SCADA systems, but monitors SCADA operations and reports data directly to the cloud.

A handful of manufacturers have devices that connect to SCADA RTUs and collect logged data from the SCADA system and transmits this data to the cloud. Basically, this device works like a translator that can communicate between the different protocols. Connexa is one of those manufacturers with its certified IIoT Cell Module. This module combined with REST Application Program Interface (API) is an agnostic system that can interface with all major SCADA protocols and transmit data, using low bandwidth, to cloud systems.

Data flow is strictly one way and modern computer security is present. Even critical alarms can be transmitted via these devices. Where SCADA systems have deficiencies, additional IoT devices can be installed to collect data (i.e., electrical power monitoring, flow rates in a pipeline, or weather data). These newer IIoT devices can network in a local area (LAN) or direct wire with a cellular modem and data can be transmitted over a virtual private network (VPN).

Recent changes in cellular networks brings quality enhanced 4G LTE service to most areas with 5G and 3.5 GHz Citizens Band Radio Network (CBRS) on the near horizon. 5G will give faster data speeds and CBRS will allow companies to set up their own private LTE network without going through a cell provider. If cell service is not available, more expensive microwave and satellite communication networks are available.

These hybrid IIoT/SCADA systems will be able to be deployed quickly and inexpensively, giving enterprise wide access to field data. Business processes can use this data in cloud computing to analyze system performance, forecast costs, and make better business decisions.

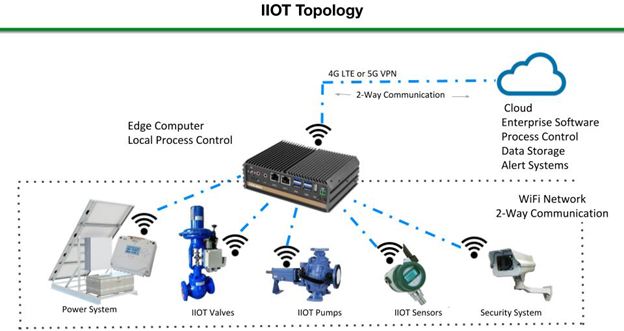

Step 2: Begin building IIoT-based automation networks. The goal of IIoT automation is to create a digital representation of processes in the field, essentially a “digital twin” of the real world. With these digital twins, powerful cloud computers with AI can create simulated models to test running conditions and predict outcomes. As new products come to market, automation components based on standard IT operating systems, network protocols, and software compatibility will be available. These systems can replace aging legacy SCADA systems in an organized, scheduled, and budgeted manner. Using onsite edge industrial computers based on client/server architecture, local wireless networks, wireless cellular modems/routers, and IIoT sensors and devices can create automation systems similar to corporate and home networks. Using edge computers locally allows real-time data acquisition and control of mission critical systems.

At today’s cellular network communication speed, latency is an issue when real-time data acquisition, computation, and control is required. Having computing and decision-making at the local level, communication and power outages become less of an issue for critical operations. Local wireless networks are easily scalable and provide flexibility of moving equipment around without having to rewire devices.

Cloud computing and AI will do the heavy lifting for complex systems computing. Software updates and security patches can be done remotely, as is done on IT systems. Currently, SCADA systems do not have this capability, causing someone to update systems onsite. Also, RTUs and PLCs only do simple logic operations in SCADA systems, limiting their capabilities. With edge computers and powerful cloud computing, systems will be able to adapt and change to conditions in the field systems. These “smart” systems will be able to predict changes in demands on equipment and make adjustments to optimize operations, reduce wear, increase life of equipment, and reduce operating costs.

Step 3: Future IIoT devices could have built in cellular modems that will allow direct communication with the cloud. As 5G communication evolves, it is possible that all control and decision-making is done in the cloud. There is debate within IT circles whether centralized, powerful, cloud computing, or distributed localized edge computing is the best route to go. This is the same debate that has gone on since we went from mainframe (centralized) to client/server (distributed) to cloud data centers (centralized). The most likely scenario is that there will be a combination of both depending on real-world needs.

Conclusions

SCADA and IT systems evolved separately, with different hardware, software, and communication protocols as well as purposes. Integration of these two very different platforms is essential to make the next step in productivity and profitability. Over time, IIoT devices will replace legacy SCADA devices and systems, creating a truly smart and networked world. Powerful cloud computing and artificial intelligence will be able to optimize machine/system/human performance and productivity.

For companies operating automation systems in remote locations, the benefits are numerous:

- Less human trips to check field equipment and record data

- Real-time alerts when systems need attention

- Enterprise-wide data-sharing

- Internet access from anywhere

- Predictive maintenance

- Systems and equipment optimization

- Trend analysis

- Longer equipment life

- Better predictions of return on investments, downtime, and other key performance indicators

- Greater profitability

Final Thoughts

In each of the previous three industrial revolutions, a breakthrough technology fundamentally changed society. In the first industrial revolution, the invention of the steam engine in the 1700s created manufacturing processes, factories, and caused people to move from the farms to cities. The second industrial revolution happened in the late 1800s with mass production and the invention of the assembly line, light bulb, telephone, and internal combustion engine. These inventions led to mobility, greater freedom, and a tremendous increase in the quality of life. The third industrial revolution occurred in the 1960s and 1970s with the invention of the semiconductor and computer. Otherwise known as the “Digital Revolution”, human feats like going to the moon, global sharing of knowledge, and exponential leaps in productivity would not have been possible.

If Industry 4.0 is as transformational as the other three revolutions, society and life-changing improvements are bound to occur. It is interesting to note that each of the previous revolutions occurred about every 100 years, but with the latest technologies, the timespan to this revolution was cut to 50 to 60 years — almost half. Also, each leap in technology created winners of those who adopted the technology, and losers of those who stuck with the “old” ways. We are definitely in transformative times.

Steve Bullard directs marketing efforts for Connexa, an award-winning industry leader in remote power and automation systems, IIoT/SCADA integration, industrial control panel fabrication, and remote electrical distribution systems. Visit https://www.connexa.com for more information.