A Game-Changing Approach To Salinity And Total Organic Carbon Treatment

By Rosa Yu, Melanie Pickett, Eva Steinle-Darling, and Vincent Hart

With applications for drinking water, wastewater, and reuse, XBAT — ion exchange-based advanced treatment — could have revolutionary, far-reaching impacts for utilities.

Water and wastewater professionals face a persistent challenge in managing salinity, a critical aspect of water quality that is often characterized through the measurement of total dissolved solids (TDS). Salinity is due to a complex mix of dissolved anions and cations, including chloride (Cl-), sulfate (SO42-), bicarbonate (HCO3-, or alkalinity), sodium (Na+), potassium (K+), calcium (Ca2+), and magnesium (Mg2+). In addition, dissolved organic matter (DOM), or total organic carbon (TOC), is an important constituent that must be managed in many water treatment applications to prevent the formation of disinfection byproducts or reduced oxygen demand in receiving waters.

Conventional water treatment methods don’t address salinity because most physicochemical and biological treatment processes don’t remove inert ions such as chloride, sulfate, and sodium. In fact, some chemical treatment processes (e.g., coagulation) add anions to the treated water. Combined with the copious use of salts in household, commercial, and industrial enterprises, this can elevate salinity in the community-wide water cycle.

Salinity removal is currently achieved through the use of reverse osmosis (RO), a highly effective, pressure-driven membrane process that removes almost all dissolved solutes, including salts. However, RO is not without challenges due to its concentrate waste stream that must be handled. This waste stream poses an issue, particularly for inland communities where ocean discharge is inaccessible or when deep well injection is not permitted, as well as for any communities where 8–15% water loss in the form of a brine waste stream is unacceptable.

Enter ion exchange-based advanced treatment (XBAT), a groundbreaking alternative method to reduce salinity. XBAT consists of a combination of two mature drinking water treatment processes:

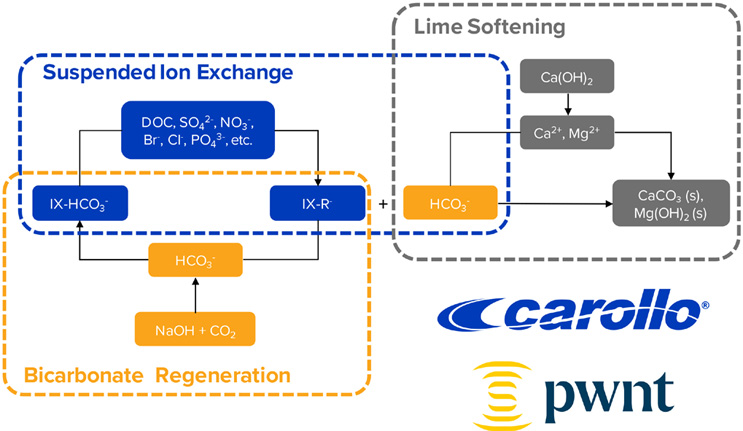

- Suspended ion exchange (SIX®, developed by PWNT) for the removal of negatively charged constituents (e.g., TOC, chloride, sulfate, bromide, nitrate, phosphate, etc.). Ion exchange resin regeneration, using bicarbonate as the counter ion, is key to the success of this approach and sets the stage for the second process.

- Lime softening for cation removal (i.e., calcium and magnesium) as well as excess bicarbonate removal through calcium carbonate (CaCO₃) precipitation.

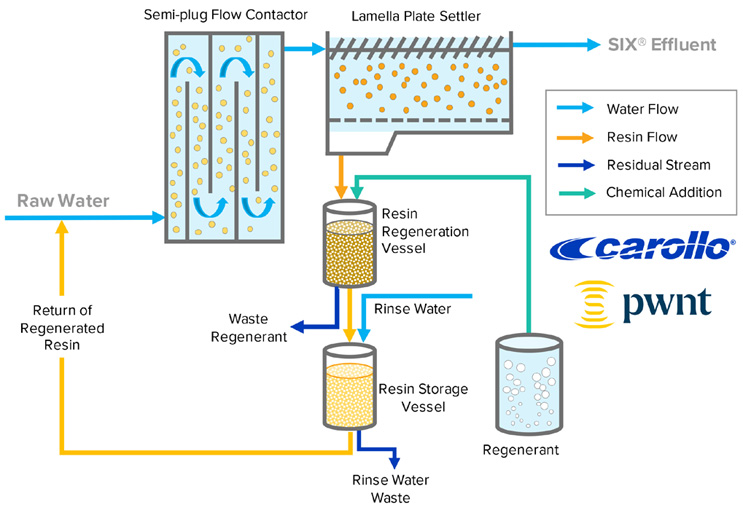

A distinctive feature of SIX® is its high resin regeneration frequency, which regenerates the spent resin after every single pass through the reactor. This keeps the resin’s ion exchange capacity only slightly utilized, allowing the resin to be regenerated by a weaker regenerant, such as bicarbonate, and at a much lower strength (3%) compared to a saturated sodium chloride solution typically used for resin regeneration. Resin regeneration using bicarbonate as the counter ion adds alkalinity to the SIX® effluent, making the treated water more suitable for lime softening and maximizes salinity reduction through calcium carbonate precipitation. Bicarbonate regeneration is the heart of XBAT, which synergizes the SIX® and lime softening processes.

Compared to RO, SIX® produces a regeneration waste stream that is only 0.8% of the total feed water flow. With XBAT, the bicarbonate nature of the waste regenerant also makes this residual stream more treatable and manageable than a concentrated chloride-based brine waste. For instance, bicarbonate, sulfate, phosphate, fluoride, arsenic, silica, and TOC in the waste brine stream could be further removed via softening reactions with magnesium hydroxide and calcium carbonate precipitation. It could also potentially serve as a beneficial amendment for alkalinity addition in biological nutrient removal processes in wastewater treatment applications, saving the costs associated with the addition of external chemicals.

Figure 1. Schematic diagram illustrating the overall XBAT chemistry and the removal mechanism for dissolved anionic and cationic solutes.

Bench-scale testing of XBAT with secondary and tertiary wastewater effluents has demonstrated a remarkable TOC removal rate of 50%, regardless of effluent type and initial TOC concentrations. High removal rates were also observed for sulfate (99%), nitrate (90%), bromide (94%), and chloride (74%). Subsequent lime softening resulted in 92% calcium removal, 96% magnesium removal, and an overall 50% net TDS reduction. These results are promising indicators of XBAT’s potential to reduce or prevent salinity upcycling in potable reuse systems.

Figure 2. Unlike conventional ion exchange in a fixed-bed configuration, SIX® is a steady-state ion exchange process that keeps the resin fluidized in a reactor.

Carollo Engineers is currently scaling up its evaluations of XBAT with an advanced wastewater treatment pilot at Tampa, FL, and a direct potable reuse treatment feasibility evaluation at Aurora Water, CO, with a pilot to follow soon.

XBAT is poised to reshape the industry by unlocking the potential of potable reuse in inland communities, including areas in Colorado, Arizona, Utah, Texas, and beyond, where moderate salinity would otherwise pose challenges in selecting an advanced treatment approach that does not include RO.

About The Authors

About The Authors

Rosa Yu, PhD, PE, is a lead technologist at Carollo Engineers. Rosa has over 10 years of experience in treating emerging contaminants via advanced treatment processes. Rosa works at the interface of engineering and applied research, and her primary focus is on the identification and development of innovative treatment technologies and control strategies in addressing emerging contaminants in drinking water and potable reuse.

Eva Steinle-Darling, PhD, PE, is Carollo Engineers’ water reuse technical practice director. She earned her doctorate from Stanford University, where she studied the removal of contaminants of emerging concern and PFAS in purified recycled water applications. Her work with Carollo focuses on all aspects of water reuse, including research, planning, feasibility studies, and design. Eva has authored over 100 publications on reuse-related topics and supported the development of sustainable regulatory approaches for potable reuse in several U.S. states and internationally. As a member of the National Legislative Committee of the Water Reuse Association and former Board Member, she is also taking part in shaping the future of water reuse policy across the U.S.

Eva Steinle-Darling, PhD, PE, is Carollo Engineers’ water reuse technical practice director. She earned her doctorate from Stanford University, where she studied the removal of contaminants of emerging concern and PFAS in purified recycled water applications. Her work with Carollo focuses on all aspects of water reuse, including research, planning, feasibility studies, and design. Eva has authored over 100 publications on reuse-related topics and supported the development of sustainable regulatory approaches for potable reuse in several U.S. states and internationally. As a member of the National Legislative Committee of the Water Reuse Association and former Board Member, she is also taking part in shaping the future of water reuse policy across the U.S.

Melanie Pickett, PhD, PE, is an engineer with Carollo Engineers. She received her PhD from the University of South Florida in environmental engineering, where her work focused on water purification technology development. She has been with Carollo for four years, spending most of her time working with organics removal technologies for drinking water and potable reuse.

Melanie Pickett, PhD, PE, is an engineer with Carollo Engineers. She received her PhD from the University of South Florida in environmental engineering, where her work focused on water purification technology development. She has been with Carollo for four years, spending most of her time working with organics removal technologies for drinking water and potable reuse.

Vincent Hart, PE, serves as executive vice president and managing director of technical practices at Carollo Engineers. With 30 years of dedicated experience in water treatment, Vincent has established himself as a leading expert in the field with a focus on innovative technologies such as pellet softening and suspended ion exchange. He has successfully led and managed multiple awardwinning microfiltration projects, both as a design engineer and project manager.

Vincent Hart, PE, serves as executive vice president and managing director of technical practices at Carollo Engineers. With 30 years of dedicated experience in water treatment, Vincent has established himself as a leading expert in the field with a focus on innovative technologies such as pellet softening and suspended ion exchange. He has successfully led and managed multiple awardwinning microfiltration projects, both as a design engineer and project manager.