A Flight Simulator For Treatment Facilities: The New Frontier For Modeling Complete Treatment Plant Operations

By Jason Curl, CH2M’s Global Service Team Leader, Software Applications and Integration, and Matt Deavenport, CH2M’s Global Technology Leader for Dynamic Simulation

Inconsistent water availability, reduced capital and operational budgets and tightening regulations are posing real challenges for our water conveyance and treatment infrastructure today. Working with clients around the world to meet these challenges, we strive to improve operational efficiency and ensure the highest water quality levels at all times. While these issues are not new, the stakes seem to be higher in recent years due to the 24-hour news cycle and potential public relations concerns that arise from these issues.

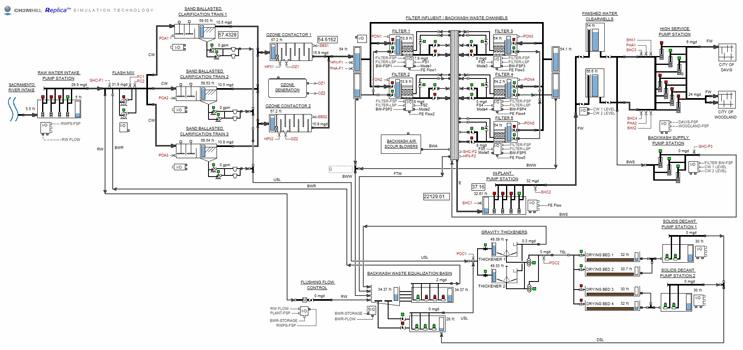

Dynamic simulation software, which leverages powerful computational capabilities and is founded on industry standard hydraulics, controls and water quality calculations, can be used to help mitigate and manage challenges with water conveyance and treatment infrastructure. CH2M’s Replica™ software is one tool that can be utilized to evaluate the abundant operational data that exists and fully understand the changing water quality, hydraulics and controls in an operational facility.

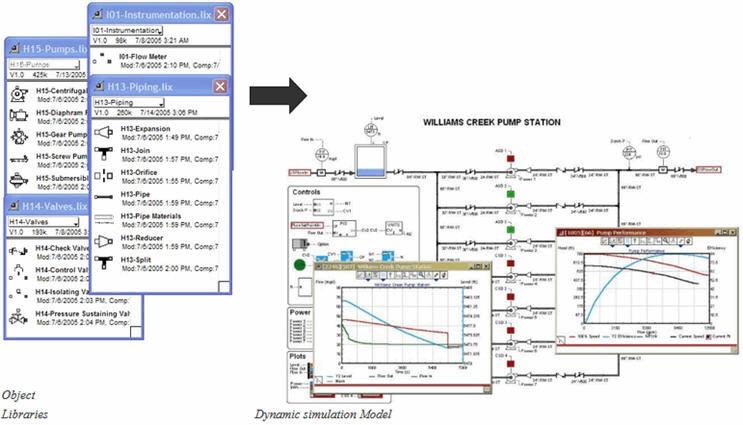

Replica is a suite of models and intelligent object libraries developed by CH2M for dynamic simulation and optimization of process systems. Figure 1 shows how Replica models are assembled from libraries of intelligent objects and can be used to simulate numerous aspects of a system, including:

- Hydraulics

- Operations and Controls

- Water Quality

- Components and Unit Operations

- Energy and Chemicals Consumption

By combining robust simulation power to evaluate extensive time-series of data with abundant data being collected at facilities, Replica truly operates like a flight simulator for the full-scale facility. The benefits of the software are many, including its ability to: (1) test extreme water quality or flow scenarios in a safe environment, (2) evaluate new control schemes against current and anticipated future demands, (3) train operators and (4) improve communication among operators, engineers and utility management with an intuitive interface.

Figure 1. Screenshots of Replica block libraries and model interface

Dynamic Simulation of Hydraulics, Controls and Water Quality

Comprehensive dynamic simulation enables improved system understanding, which leads to improved design coordination, more efficient solutions and optimized operations. CH2M’s Replica dynamic simulation model can be applied at various phases of a facility’s lifecycle, which can start with a theoretical model during facility design and can be calibrated during the operations phase.

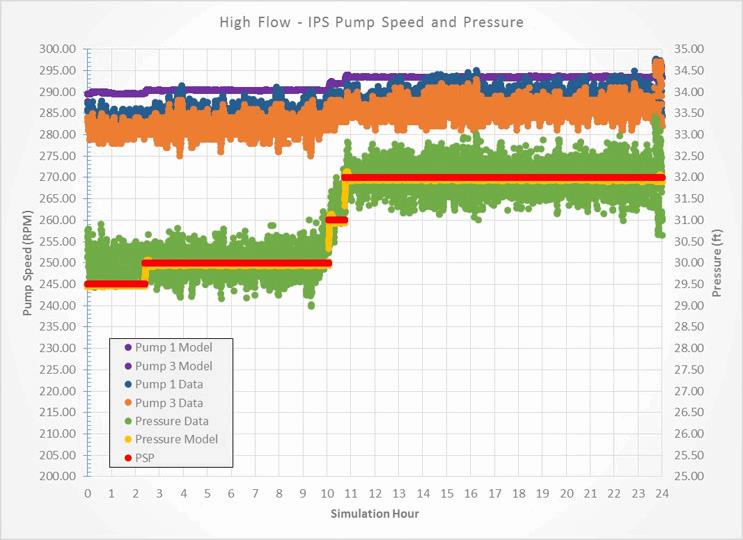

During the design phase of a facility, the dynamic simulation model can be used to confirm equipment sizing and selection, evaluate system pressure and gravity hydraulics and develop fundamental control strategies and preliminary control set-points. Further evaluation and optimization can be performed on the design for various parameters, such as operating costs, power consumption, chemical usage, water loss and process control tuning set-points. Figure 2 shows how testing the model in a computer environment can lead to deep insights into the real performance in the field.

Figure 2. Comparison of Pump Feedback and Pressure at a Pump Station

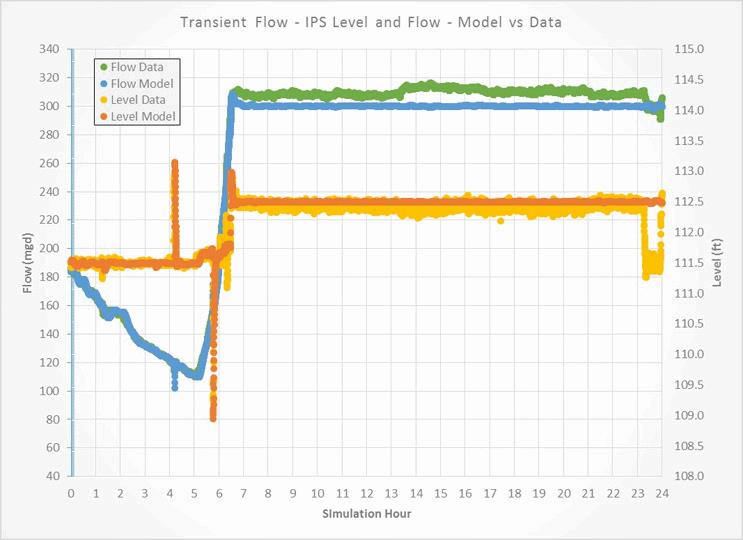

During the commissioning phase, a dynamic simulation tool such as Replica, can aid control system testing and operator training. The process control logic programmed in the programmable logic controllers (PLCs) installed in the field are tested and tuned against the model prior to field installation — minimizing programming changes in the field and ensuring programming reliability against future conditions. Next, the model can be linked to the supervisory control and data acquisition (SCADA) software to provide a realistic “flight simulator” of the system for operator training. This simulator provides operators insight in operating the system under expected hydraulics and water quality conditions with the actual PLCs, prior to actual facility operations. Figure 3 shows how the results of developing the process control philosophy with a full understanding of the system performance can result in highly stable operation.

Figure 3. Comparison of Flow and Level at a Pump Station during a Transient Flow Event

Being able to visualize the complex interconnectivity between systems while considering hydraulics, controls and process performance simultaneously has added value to hundreds of projects around the world. This increased system understanding reduces performance risk, increases performance under extreme conditions and aids in overall system optimization of energy, solids and chemicals. Dynamic simulation model application with tools like Replica, indicate a real market shift towards being able to truly optimize complex water and wastewater systems.

Jason Curl is a Principal Water Treatment Technologist and CH2M’s Global Service Lead (GSL) for Software Applications and Integration. Jason joined the firm in 2003 and is located in the Denver, Colorado, office. In his role as GSL, he is responsible for leading the development and leveraging of software technologies that improve team performance, communication and quality. As a Principal Technologist for water treatment, Jason focuses on conventional treatment and membrane filtration technologies for both public and private clients. He graduated from the University of Illinois at Urbana-Champaign with his B.S. and M.S. in Environmental Engineering in 2003.

Jason Curl is a Principal Water Treatment Technologist and CH2M’s Global Service Lead (GSL) for Software Applications and Integration. Jason joined the firm in 2003 and is located in the Denver, Colorado, office. In his role as GSL, he is responsible for leading the development and leveraging of software technologies that improve team performance, communication and quality. As a Principal Technologist for water treatment, Jason focuses on conventional treatment and membrane filtration technologies for both public and private clients. He graduated from the University of Illinois at Urbana-Champaign with his B.S. and M.S. in Environmental Engineering in 2003.

Matt Deavenport joined CH2M in 2006 as an intern and is currently a project technologist with CH2M’s Global Water Business Group in Pensacola. As CH2M’s Global Technology Leader for Dynamic Simulation, he leads development and application of our in-house software Replica™ dynamic simulation for optimization and simulation of water and wastewater systems, both municipal and private. Matt graduated from the University of Florida with his B.S. in Civil Engineering (2007) and M.S. in Coastal and Oceanographic Engineering (2008).

Matt Deavenport joined CH2M in 2006 as an intern and is currently a project technologist with CH2M’s Global Water Business Group in Pensacola. As CH2M’s Global Technology Leader for Dynamic Simulation, he leads development and application of our in-house software Replica™ dynamic simulation for optimization and simulation of water and wastewater systems, both municipal and private. Matt graduated from the University of Florida with his B.S. in Civil Engineering (2007) and M.S. in Coastal and Oceanographic Engineering (2008).