Fresenius Kabi Relies On Swan's AMI LineTOC

The Production Site

Fresenius Kabi is a global healthcare company that is specialized in lifesaving medicines and technologies for injection, transfusion and clinical nutrition.

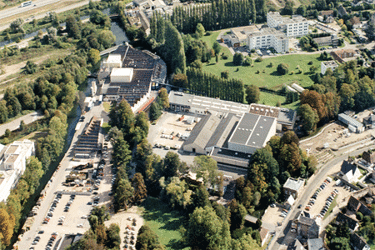

The Louviers production site is located in Upper Normandy, about 100 km northwest of Paris. This site is now one of Fresenius Kabi's competence centers for terminal sterilized IV bags for injection and irrigation solutions for European markets.

The manufacturing plant is designed for high volume batch sizes up to 30,000 liters.

Project Description

The Utilities Service Manager of the site contacted Best Water Technologies Permo (a global water treatment and services company) regarding online TOC measurement in September 2014.

Indeed, on initial installation the system offered no continuous measurement with TOC testing performed only as a follow-up measurement in the laboratory.

Why Swan Won

The site had previously been equipped mainly with a competitor's conductivity analyzers. The analyzers were available at a lower price than the Swan instruments. However, the lack of response from the competitor on the project, and Swan's proposal to provide a demonstration of the instrument convinced Fresenius to test the Swan analyzer.

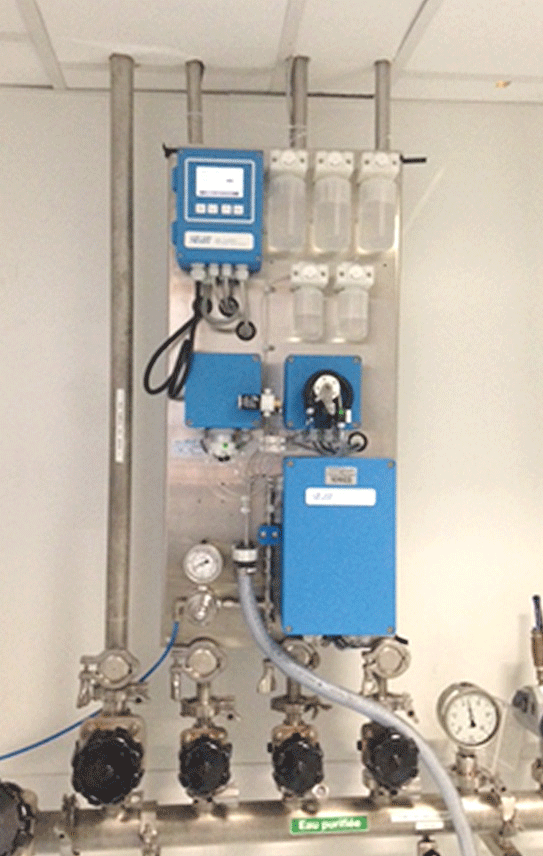

The AMI LineTOC analyzer was installed on September 30, 2014. The customer was able to test the instrument for a month. On October 28, the client confirmed their commitment to keep the instrument. They appreciated the high responsiveness and the easy operation of the Swan AMI LineTOC analyzer. Fresenius also appreciated that they could perform maintenance on the instrument themselves or contract with Swan for maintenance. In the end our service team's offer for a reasonably priced 3-year maintenance contract convinced the customer to have Swan provide maintenance.

Following a contamination problem at the WFI production, one of the ion exchange resin lines was replaced. The site decided to implement a continuous monitoring on the upstream purified water loop with alarms in case of problems to be able to intervene at the source.

The BWT Normandy agency manager contacted us to propose a technical test on the site.