WWEMA Window: Clarifying 'Precision' With Circular Clarifier Drives

By Michelle McNish

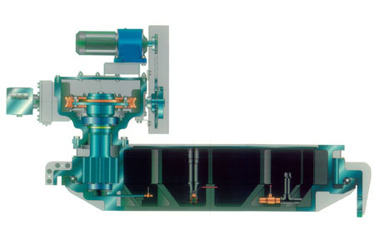

The thousands of circular clarifier mechanisms that have been a key component in our domestic treatment plants for generations create a large market for new, replacement, and rehabilitation of drive mechanisms. Not surprisingly, several of the manufacturers who produce these specialty drive assemblies compete for their share of the market in just about every way they can think of — one of which is touting the virtues of their drive units. Since most of us who have an interest in clarifier drives either from use, replacement, or crafting specifications for new ones are not specialists in gear design, we are subject to the influence of marketing efforts by the various manufacturers. This is the kind of thing psychologists do for marketing people — develop words and images that trigger the notion of superiority in a marketing message.

During the past decade or more, the term “precision” has infiltrated the area of circular clarifier drive marketing, and, certainly, precision and (gear) drive simply sound good together. The first thought that likely comes to mind when discussing a ‘precision gear’ is that ‘precision’ must make the gear better. Another associated concept would be the transference of the ‘precision’ of the gear to the entire system, including the integral or separate turntable bearing. Also, it would follow that those drives lacking the adjective ‘precision’ must be an inferior product.

In an effort to understand and more clearly define ‘precision’, we can investigate the American National Standards Institute (ANSI), standards. The American Gear Manufacturers Association (AGMA) develops standards that are reviewed by both AGMA and ANSI members prior to acceptance. In the ANSI/AGMA standards, there is a dramatic absence of any mention or definition of the term ‘precision’ or ‘precision gear’. On the other hand, there is a great deal of discussion concerning Quality Classifications as found in ANSI/AGMA 2000-A88, AMERICAN NATIONAL STANDARD: Gear Classification and Inspection Handbook—Tolerances and Measuring Methods for Unassembled Spur and Helical Gears (Including Metric Equivalents). AGMA Quality Class 3 is the lowest quality level and Class 15 is the highest quality level assigned by this standard.

A clarifier drive manufacturer might state that their internal spur gear cut to an AGMA Quality Class 6 and de-rated to an AGMA Quality Class 5 after heat treatment is a ‘precision gear’. By the manufacturer’s definition, this may be true, as ANSI/AGMA has no definition of ‘precision’. The question then becomes, if one or more drive manufacturers produce gears that have a higher AGMA Quality Class 6 rating as a minimum final gear rating but do not use the term ‘precision’, which gear is better? The one with the higher AGMA class rating without the term ‘precision’ or the gear with the lower AGMA Class rating that uses the term ‘precision?’

Perhaps, the much-touted ‘precision’ then resides in the bearing. ANSI and the American Bearing Manufacturers Association (ABMA) publish standards specifying rolling element bearings. The old Anti-Friction Bearing Manufacturers Association (AFBMA) Standard 1 Terminology for Anti-Friction Ball and Roller Bearing Parts defines internal clearance, axial clearance, radial clearance, and radial play. Standard 1 does not define ‘precision’, but does use precision in the definition of Annular Bearing Engineering Committee (ABEC) standard for tolerances for ABEC-1, ABEC-3, ABEC-5, ABEC-7, and ABEC-9, as the class or degree of precision of radial ball bearings.

ANSI/ABMA Standard 4, Tolerance Definitions and Gaging Practices for Ball and Roller Bearings, defines ‘Tolerance Terms’, ‘Internal Clearance’, and gives descriptions of methods of measuring commonly used that give accuracy sufficient for practical purposes. This standard, however, does not give ranges or recommended values for either tolerances or clearances for bearing design and does not refer to ‘precision’ at all.

ANSI/ABMA Standard 9, Load Ratings and Fatigue Life for Ball Bearings and ANSI/ABMA Standard 20, Radial Bearings of Ball, Cylindrical Roller and Spherical Roller Types, Metric Design do not include 4-point Gothic-Arch bearings within their scope. ANSI/ABMA Standard 20, Radial Bearings of Ball, Cylindrical Roller and Spherical Roller Types, Metric Design does define ABEC and Roller Bearing Engineering Committee (RBEC) Tolerance Classes; however, the 4-point Gothic-Arch bearing is not within its scope.

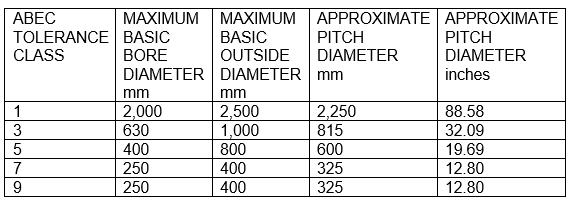

The following chart presents the maximum bearing diameters for the various ABEC tolerance classes.

As demonstrated in the above chart, for any ball bearing having a pitch diameter above 32 inches, only the ABEC-1 would apply. Thus, the ‘precision’ of the ‘precision gear’ must not be driven by the bearing tolerance and geometry, as ABEC-1 is the normal or customary tolerance.

The definition of ‘precision’ must then come from the manufacturer, and is not based on the gear Quality Classification Number nor the tolerances associated with the bearing.

One or more specialty companies (not clarifier gear manufacturers) do offer precision bearing and gear assemblies with runout tolerances of 0.0002” to 0.0006” with an integral AGMA Quality Class 10 gear. These bearing and gear assemblies are for test stands, medical diagnostic equipment, precision indexing tables, and radar or radio telescope antennae. An AGMA Quality Class 5 or 6 gearing described by a clarifier drive manufacturer would not be incorporated into a precision system.

Specifiers and buyers beware! Be informed of what you are specifying or buying and do your best to not be overly influenced by implied concepts when words like precision are used.

Michelle McNish is President of Walker Process Equipment, a Division of McNish Corporation. She is also a Board Member of the Water and Wastewater Equipment Manufacturers Association (WWEMA), a non-profit trade association that has been representing water and wastewater technology and service providers since 1908. WWEMA’s members supply the most sophisticated leading-edge technologies and services, offering solutions to every water-related environmental problem and need facing today’s society. For more information about WWEMA go to www.wwema.org.